Continuous testing method for platinum and palladium in ore

A measurement method and ore technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, etc., can solve the problems of unsuitable batch sample determination, extraction agent volatilization, human hazards, etc. problem, to achieve the effect of eliminating the interference of a small amount of iron, wide acidity range, and easy to grasp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

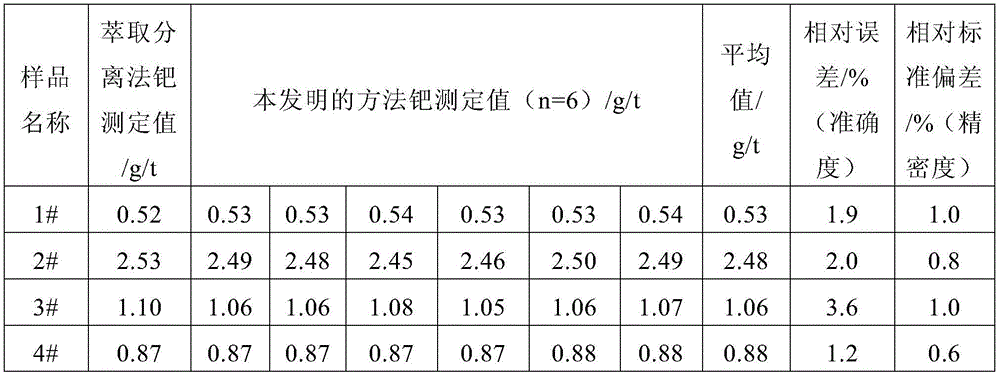

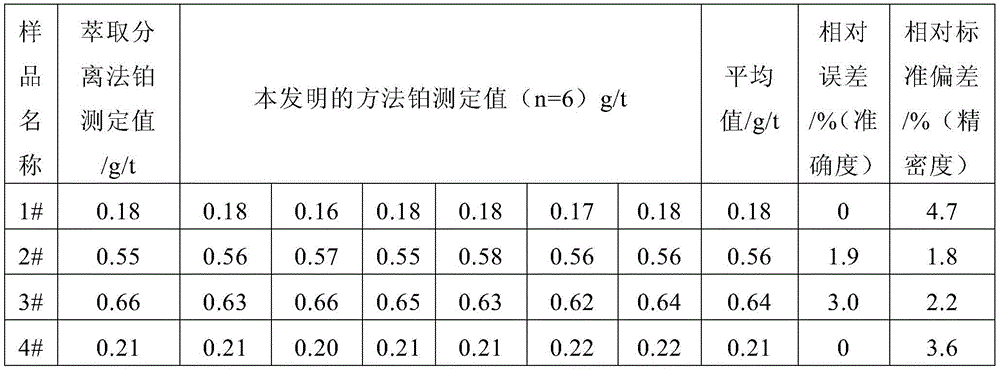

Embodiment 1

[0033] Accurately weigh 23.5698g of sample 1# into a porcelain boat, place the porcelain boat in a muffle furnace, heat up to 750°C, burn for 4 hours, transfer the sample into a 250mL beaker after cooling, add 30mL of concentrated hydrochloric acid, 5mL of hydrogen peroxide ( Concentration is 30%), heated and melted on electric furnace for 30 minutes. Add water to dilute to 100mL, boil on an electric stove, cool to 40-50°C, filter with Buchner funnel equipped with activated carbon adsorption column, wash with dilute hydrochloric acid with a concentration of 0.24mol / L, and then wash with water. The activated carbon column was taken out, placed in a porcelain crucible, put into a muffle furnace, and fired at 750°C for 3 hours. After taking out and cooling, moisten the residue with a small amount of water, add 4mL of aqua regia, dissolve on an electric furnace at 150°C, transfer the solution into a beaker, add 2 drops of saturated sodium chloride solution, evaporate to nearly dry...

Embodiment 2

[0035]Accurately weigh 20.0560g of sample 2# into a porcelain boat, place the porcelain boat in a muffle furnace, heat up to 730°C, burn for 3 hours, transfer the sample into a 250mL beaker after cooling, add 40mL of concentrated hydrochloric acid, 7mL of hydrogen peroxide ( Concentration is 30%), heated and melted on electric furnace for 30 minutes. Add water to dilute to 100mL, boil on an electric stove, cool to 40-50°C, filter with Buchner funnel equipped with activated carbon adsorption column, wash with dilute hydrochloric acid with a concentration of 0.24mol / L, and then wash with water. The activated carbon column was taken out, placed in a porcelain crucible, put into a muffle furnace, and fired at 750°C for 3 hours. After taking out and cooling, moisten the residue with a small amount of water, add 5mL of aqua regia, dissolve on an electric furnace at 170°C, transfer the solution into a beaker, add 3 drops of saturated sodium chloride solution, evaporate to nearly dry ...

Embodiment 3

[0037] Accurately weigh 21.1687g of sample 3# into a porcelain boat, place the porcelain boat in a muffle furnace, heat up to 750°C, burn for 5 hours, transfer the sample into a 250mL beaker after cooling, add 40mL of concentrated hydrochloric acid, 8mL of hydrogen peroxide ( Concentration is 30%), heated and melted on electric furnace for 40 minutes. Add water to dilute to 110mL, boil on an electric furnace, cool to 40-50°C, filter with Buchner funnel equipped with activated carbon adsorption column, wash with dilute hydrochloric acid with a concentration of 0.24mol / L, and then wash with water. The activated carbon column was taken out, placed in a porcelain crucible, and the porcelain crucible was put into a muffle furnace, and fired at 740° C. for 4 hours. After taking out and cooling, moisten the residue with a small amount of water, add 5mL of aqua regia, dissolve it on an electric furnace at 180°C, transfer the solution into a beaker, add 2 drops of saturated sodium chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com