Water migration detection method in cooling process after killing of pig

A detection method and cooling process technology, applied in the direction of material analysis through resonance, measuring devices, and analysis materials, etc., can solve the problems of small meat samples, large sample damage, and affecting the accuracy and representativeness of measurement results, and meet the requirements of The need for the determination of large samples and the effect of accurate sample information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

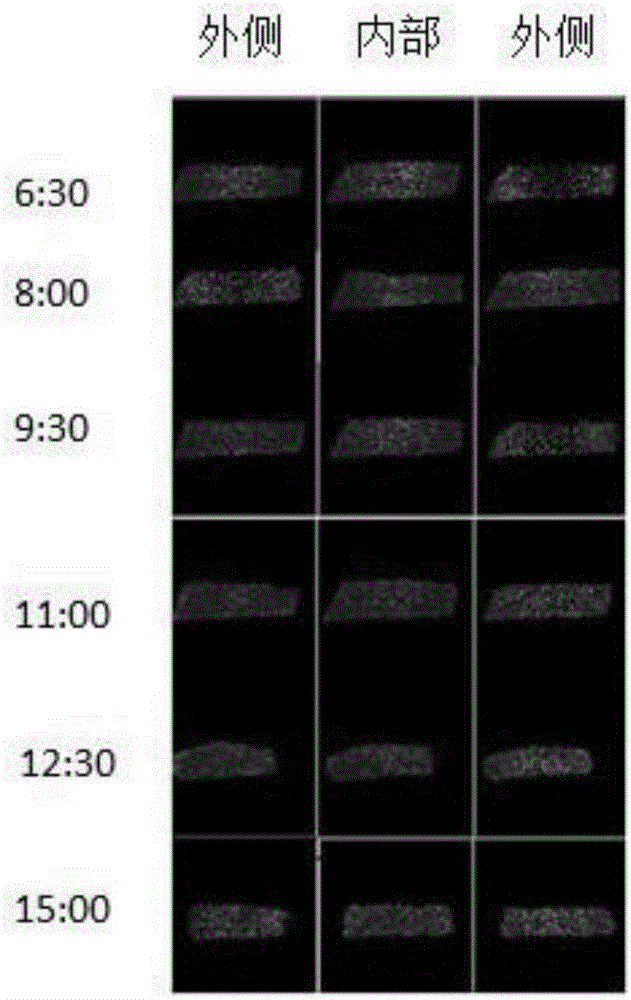

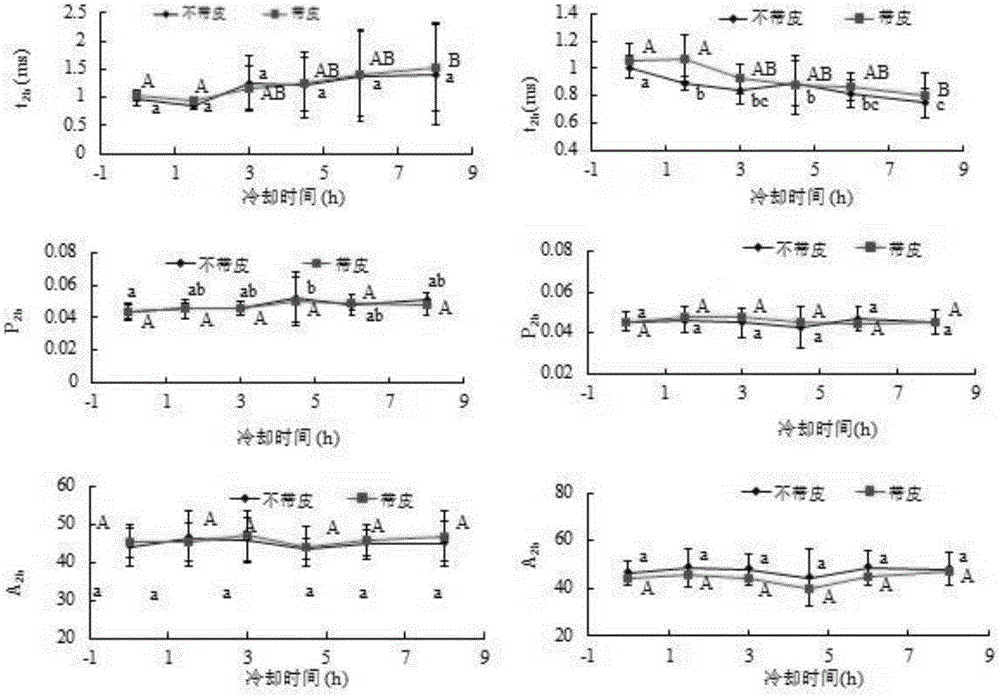

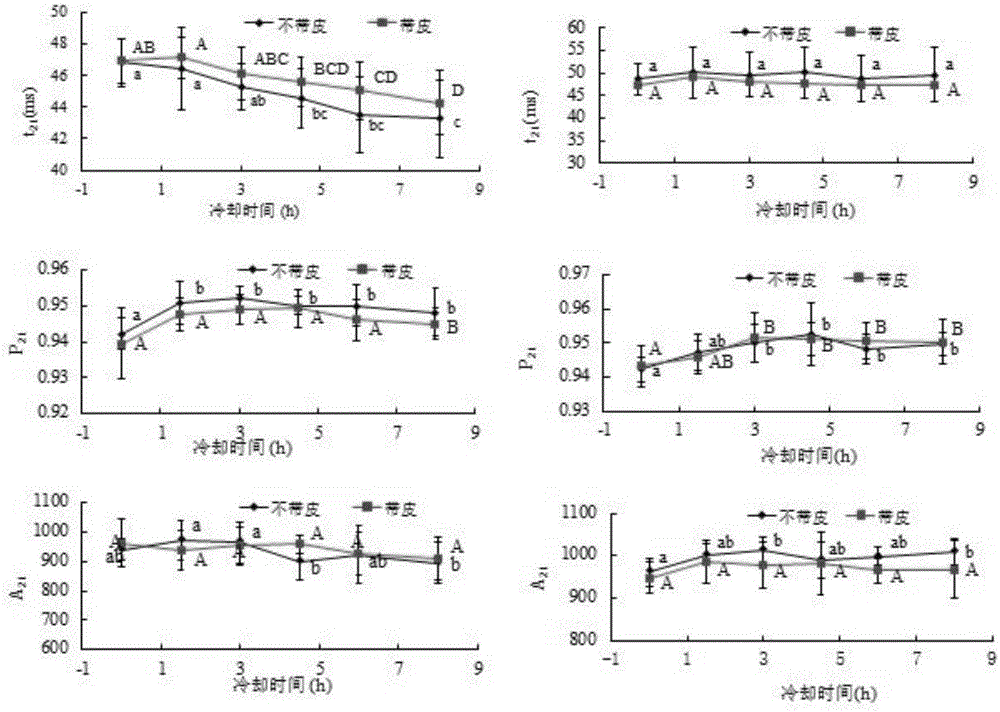

[0026] (1) Raw material selection: select the whole longissimus dorsi (tong ridge) within 2 hours after slaughter, take meat pieces with a size of 14×10×6 cm along the direction perpendicular to the muscle, and divide them into 2 groups (one group removes pigs The fascia tissue on the surface of the skin and pork is used as the red strip group; one group retains the fascia tissue on the surface of the pig skin and pork, and the fascia tissue with a dense structure and a certain thickness is simulated as a fat layer, which is used as the white strip group). Blowing cooling and atomizing spray cooling were carried out in the cold storage environment, and the meat samples were subjected to low-field nuclear magnetic resonance transverse relaxation time at 6:30, 8:00, 9:30, 11:00, 13:30 and 15:00, respectively. (T2) and low-field MRI measurements.

[0027] (2) Low-field nuclear magnetic imaging: The SE imaging sequence test was used to change the proton density and the influence o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com