Preparation method of sulfide nano-compound counter electrode based on porous CuS architecture

A nanocomposite and sulfide technology, applied in the field of quantum dot-sensitized solar cells, can solve the problems of photoanode poisoning, increased contact resistance, and reduced adhesion, and achieve improved battery performance, improved catalytic activity, and improved electrode stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

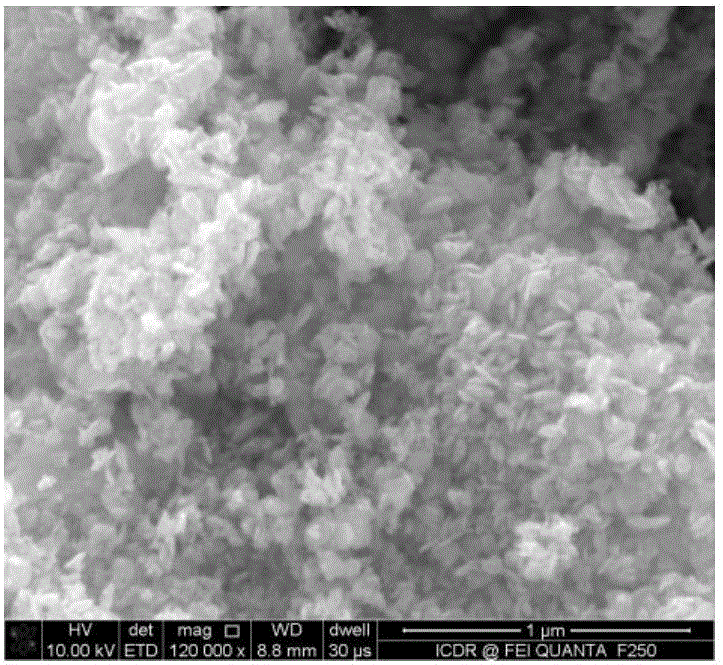

[0045] The preparation method of the sulfide nanocomposite counter electrode based on the porous CuS framework is specifically implemented according to the following steps:

[0046] Step 1, preparing CuS nanopowder;

[0047] Step 1.1, use a magnetic stirrer to equip Na with a concentration of 0.4M 2 S aqueous solution and CuSO 4 aqueous solution;

[0048] Step 1.2, Na 2 S aqueous solution was slowly injected into CuSO 4 In the aqueous solution, the CuS precipitate obtained by the reaction was collected by centrifugation after sufficient reaction;

[0049] Step 1.3, using deionized water to wash the CuS precipitate obtained in step 1.2 3-5 times, and then using absolute ethanol to wash the CuS precipitate 3-5 times;

[0050] Step 1.4, place the washed CuS precipitate in a vacuum drying oven at 40°C for drying, and finally grind and disperse the dried CuS precipitate into CuS nanopowder;

[0051] Step 2, making CuS slurry from the CuS nanopowder prepared in step 1;

[005...

Embodiment 2

[0068] The preparation method of the sulfide nanocomposite counter electrode based on the porous CuS framework is specifically implemented according to the following steps:

[0069] Step 1, preparing CuS nanopowder;

[0070] Step 1.1, use a magnetic stirrer to equip Na with a concentration of 0.5M 2 S aqueous solution and CuSO 4 aqueous solution;

[0071] Step 1.2, Na 2 S aqueous solution was slowly injected into CuSO 4 In the aqueous solution, the CuS precipitate obtained by the reaction was collected by centrifugation after sufficient reaction;

[0072] Step 1.3, using deionized water to wash the CuS precipitate obtained in step 1.2 3-5 times, and then using absolute ethanol to wash the CuS precipitate 3-5 times;

[0073] Step 1.4, place the washed CuS precipitate in a vacuum oven at 50°C for drying, and finally grind and disperse the dried CuS precipitate into CuS nanopowder;

[0074] Step 2, making CuS slurry from the CuS nanopowder prepared in step 1;

[0075] Step...

Embodiment 3

[0092] The preparation method of the sulfide nanocomposite counter electrode based on the porous CuS framework is specifically implemented according to the following steps:

[0093] Step 1, preparing CuS nanopowder;

[0094] Step 1.1, use a magnetic stirrer to equip Na with a concentration of 0.6M 2 S aqueous solution and CuSO 4 aqueous solution;

[0095] Step 1.2, Na 2 S aqueous solution was slowly injected into CuSO 4 In the aqueous solution, the CuS precipitate obtained by the reaction was collected by centrifugation after sufficient reaction;

[0096] Step 1.3, using deionized water to wash the CuS precipitate obtained in step 1.2 3-5 times, and then using absolute ethanol to wash the CuS precipitate 3-5 times;

[0097] Step 1.4, place the washed CuS precipitate in a vacuum drying oven at 60°C for drying, and finally grind and disperse the dried CuS precipitate into CuS nanopowder;

[0098] Step 2, making CuS slurry from the CuS nanopowder prepared in step 1;

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com