Radio frequency chip connecting piece assembly and preparation technology thereof

A radio frequency chip and preparation process technology, applied in the field of radio frequency, can solve the problems of high manufacturing cost, complex manufacturing process, large waste water, etc., and achieve the effects of small overall thickness, low manufacturing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further described below in conjunction with accompanying drawing and embodiment:

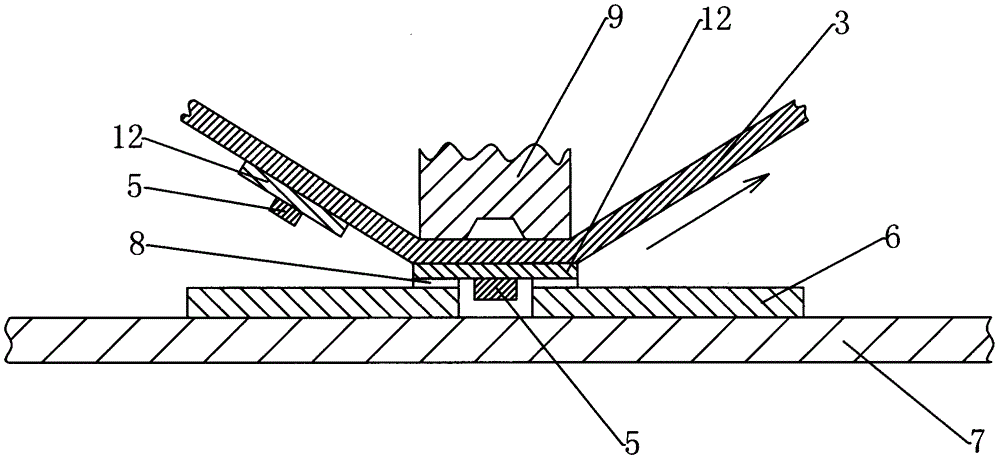

[0046] Such as figure 1 As shown, a radio frequency chip connection sheet assembly, including a PET-aluminum foil composite film and a schematic diagram of the application of the radio frequency chip 5 installed on the aluminum foil antenna.

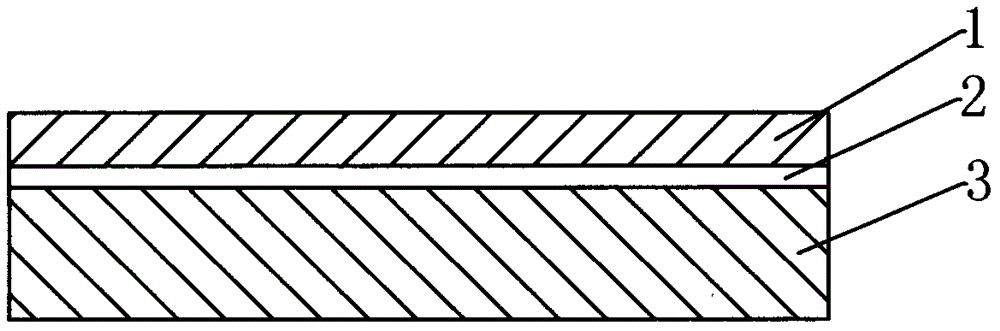

[0047] Such as figure 2 As shown, the PET-aluminum foil composite film material includes chip stakes connecting the aluminum foil 1 and the PET base film 3, and the aluminum foil 1 and the PET base film 3 are connected by a composite glue 2, and the composite glue 2 loses adhesion at 80°C to 90°C Force, easy to separate aluminum foil and PET film.

[0048] The thickness of the PET base film 3 is not less than 40 microns, and the thickness of the aluminum foil 1 is 9-5 microns.

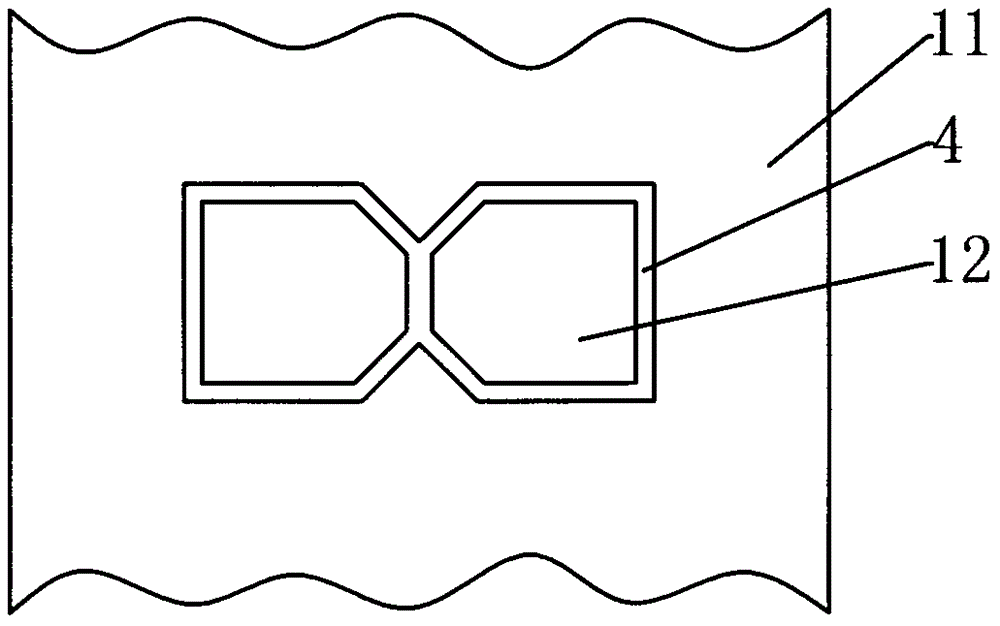

[0049] Such as Figure 3-17 Shown, a kind of preparation technology of radio frequency chip connecting sheet assembly comprises the following s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com