Infrared detector for preparing titanium oxide electrodes through ion implantation and preparation method of infrared detector

An infrared detector and ion implantation technology, applied in electrical radiation detectors, circuits, electrical components, etc., can solve problems such as poor compatibility of integrated circuit manufacturing processes, affect yield, contaminate equipment, etc., to improve productivity and efficiency , the effect of increasing production capacity and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

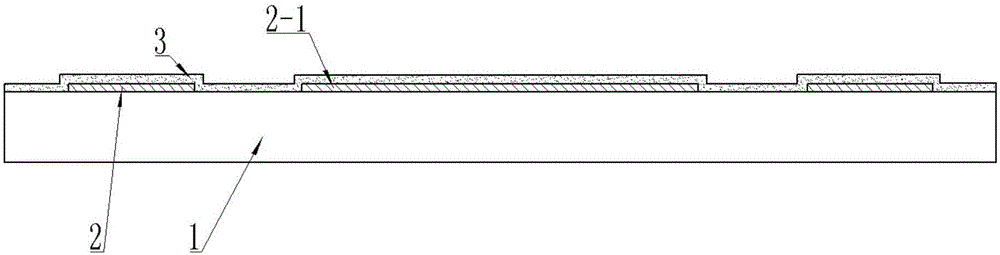

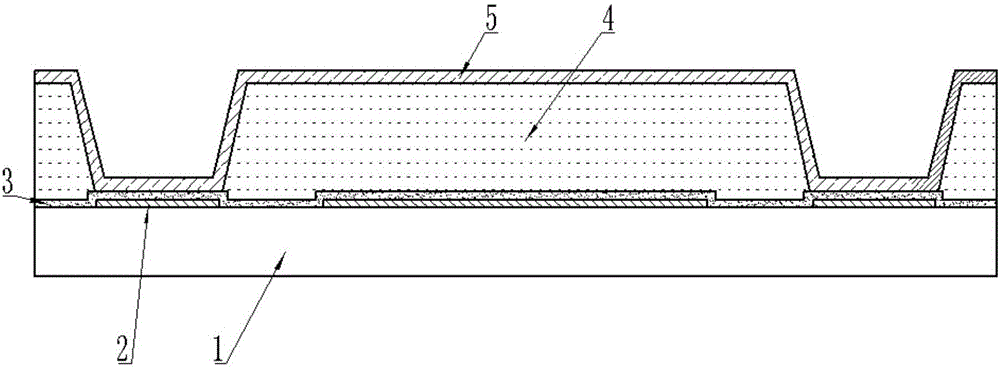

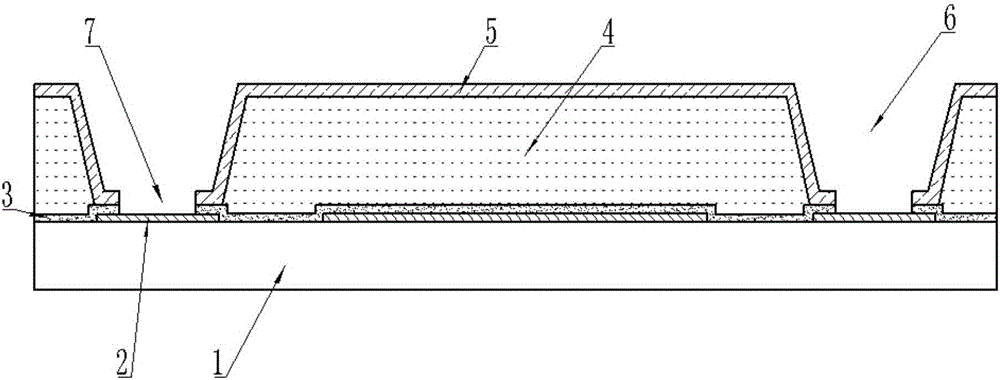

[0043] The invention relates to an infrared detector prepared by ion implantation into a titanium oxide electrode, such as Figure 11As shown, an infrared detector prepared by ion implantation with a titanium oxide electrode includes a semiconductor base 1 with a readout circuit and a detector body electrically connected to the semiconductor base 1, and the detector body includes a metal reflective layer 2 , an insulating medium layer 3, a supporting layer 5 and a titanium oxide film 9, the semiconductor base 1 is provided with a metal reflective layer 2 and an insulating medium layer 3, and the metal reflective layer 2 includes several metal blocks 2-1;

[0044] The insulating medium layer 3 is provided with a supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com