Carbon fiber woven ball top, vibrating diaphragm structure and manufacturing method

A carbon fiber weaving and carbon fiber cloth technology, applied in the fields of carbon fiber weaving dome, diaphragm structure and production, can solve the problems of broken aluminum foil, insufficient material strength, inability to withstand pressure, etc., to reduce the thickness of the dome and increase the material strength , good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

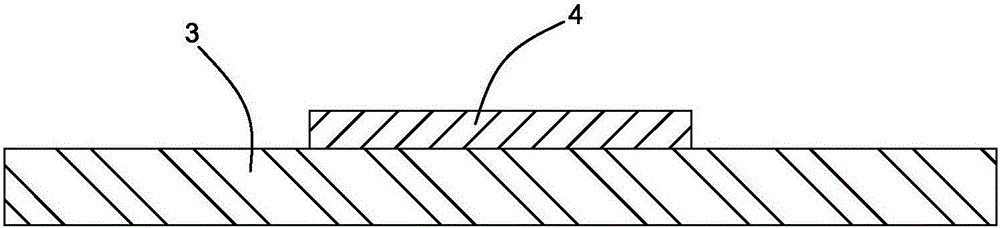

[0020] A carbon fiber braided dome is made of carbon fiber cloth. In the present invention, the carbon fiber cloth may be one layer, or may be composed of multiple layers of carbon fiber cloth, and each layer of carbon fiber cloth may be combined by bonding or weaving.

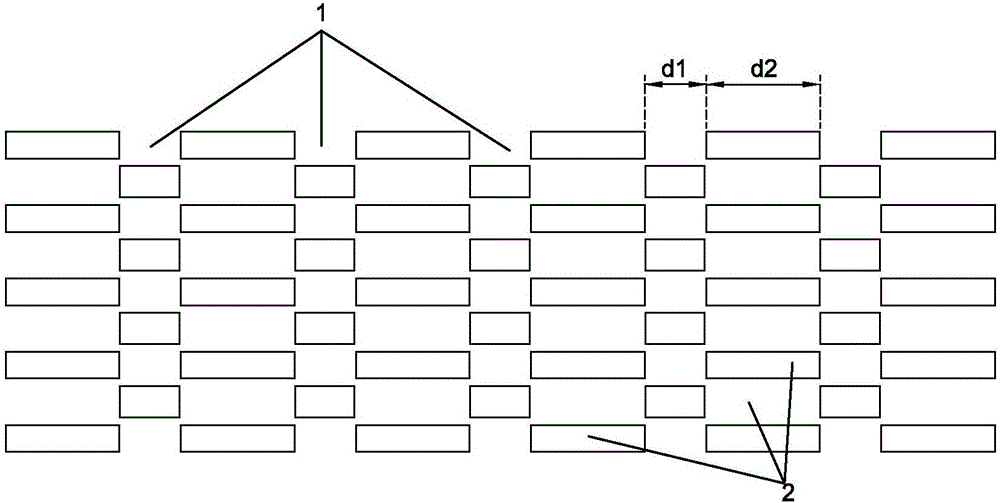

[0021] Such as figure 1 As shown, in the present invention, the weaving proportions of the carbon fiber cloth in the vertical and horizontal directions are different, which can provide unidirectional strength and make it adaptable to spherical tops of different shapes. The weaving ratio of carbon fiber cloth includes an aspect ratio of 1:20 to 1:2. The so-called aspect ratio refers to the ratio of the width (diameter) d1 of a longitudinal carbon fiber filament 1 to the distance d2 between two adjacent longitudinal carbon fiber filaments 1 , that is, d1:d2 is 1:20~1:2. exist figure 1 Among them, the aspect ratio between the so-called longitudinal carbon fiber filaments 1 and the transverse carbon fiber filam...

Embodiment 2

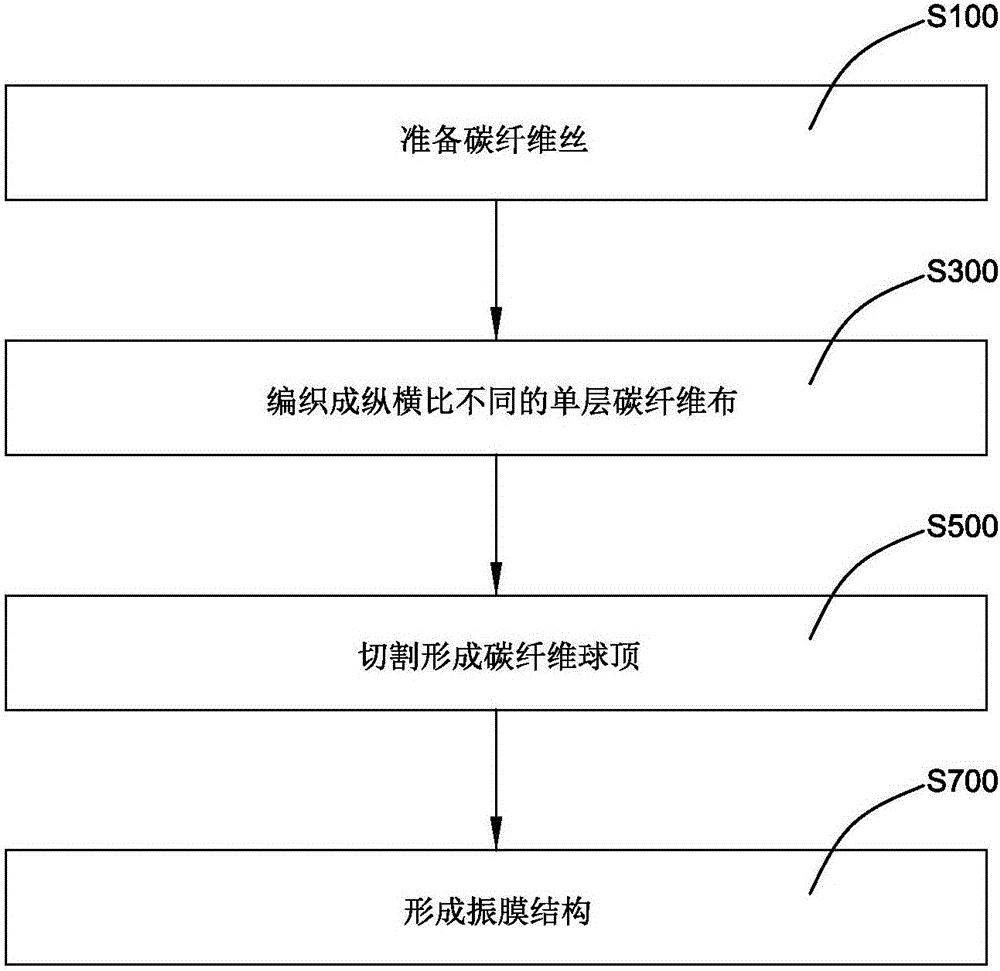

[0027] Combine below image 3 The manufacturing method of the carbon fiber braided dome and diaphragm structure in the present invention is further introduced.

[0028] S100: Prepare carbon fiber filaments. The tensile modulus of the carbon fiber filament is above 300Gpa. Further, the carbon fiber filaments are carbon fiber filaments that have been pre-impregnated with resin. Prepreg resins include epoxy resin, PEEK (polyether ether ketone), PI (polyimide), PPS (polyphenylene sulfide), PBO (poly-paraphenylene benzobisoxazole), aramid 1414, etc.

[0029] S300: Weaving the carbon fiber filaments in step S100 into single-layer carbon fiber cloths with different aspect ratios. The aspect ratio of the carbon fiber cloth is 1:20~1:2, and the thickness range is 20~200um, preferably 80~150um.

[0030] S500: Cutting to form the carbon fiber dome, for example, laser cutting, trimming die cutting, die cutting machine die cutting, etc. can be used.

[0031] S700: The cut carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com