A Reshaping Method for Quenching Deformation of Ultra-High Strength Steel Thin-walled Shell

A technology of ultra-high-strength steel and thin-walled shells, applied in the field of heat treatment, can solve problems such as increasing product development cycle, reducing pass rate, and assembly difficulties, and achieves the effects of ensuring dimensional stability, high pass rate, and eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

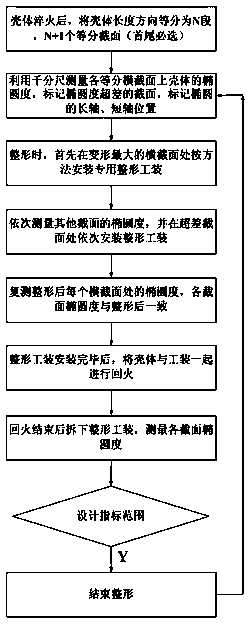

Method used

Image

Examples

example

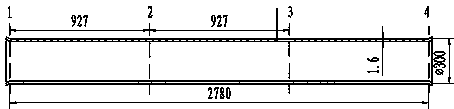

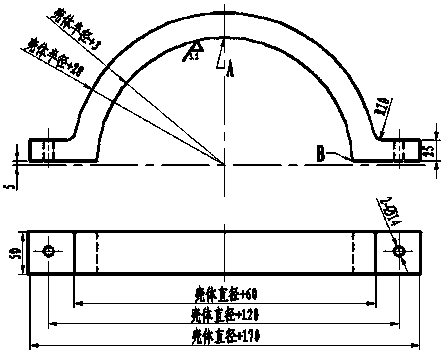

[0024] It is implemented on a 30Cr3SiNiMoVA thin-walled shell with a diameter of about 300mm, a length of 2780mm, and a wall thickness of 1.6mm. The design index is that the roundness of the shell is ≤2㎜ (the ellipticity is ≤4㎜). The specific method is as follows:

[0025] Step 1. After the shell is quenched, divide the shell into three sections in the length direction and four equal sections. The section must not be located at the non-linear sections at both ends, such figure 2 shown;

[0026] Step 2. Use a micrometer to measure the ellipticity of the shell on each equal cross-section, mark the sections 1, 2, and 4 where the ellipticity is out of tolerance, and mark the positions of the major and minor axes of the ellipse; see Table 1 for specific data:

[0027] Table 1 Quenching deformation data of 30Cr3SiNiMoVA thin-walled shell

[0028] section

Section 1

Section 2

Section 3

Section 4

Long axis (㎜)

300﹢4.75

300﹢3.27

300﹢1.96

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com