Aluminum ingot heating and melting furnace using biomass fuel

A technology of biomass fuel and melting furnace, which is applied in the field of aluminum ingot melting furnace, can solve the problems that have not been effectively solved, and achieve the effect of good promotion value, simple composition, good construction and system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

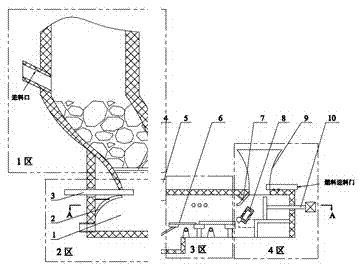

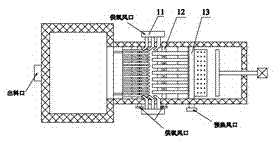

[0011] Combine below Attached picture The present invention is described in further detail.

[0012] Installation: The overall structure of the furnace is L-shaped. Zone 1 is the raw material heating part and Zone 2 is the melting pool at the bottom of the furnace. The structural relationship is superimposed, forming an L-shaped vertical part. The main function of Zone 1 is to accommodate alloy raw materials and absorb For convective heat heating, the melting furnace hearth (1) in zone 2 holds the molten liquid alloy, and the radiant heat reflection plate (2) uses radiant heat to heat the melting furnace hearth (1), and the convective heat heating control door (3) It is a structure that can be opened and closed to control the temperature of zones 1 and 2. The other end of zone 2 is connected to the combustion chamber of zone 3. The flame outlet control door (5) is an openable structure that can control the temperature of zones 1 and 2. The heating is controlled, and the dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com