Titanium oxide supported sub-nano rhodium catalyst and preparation and application thereof

A rhodium catalyst, catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. The effect of low temperature catalytic oxidation performance and high decomposition activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

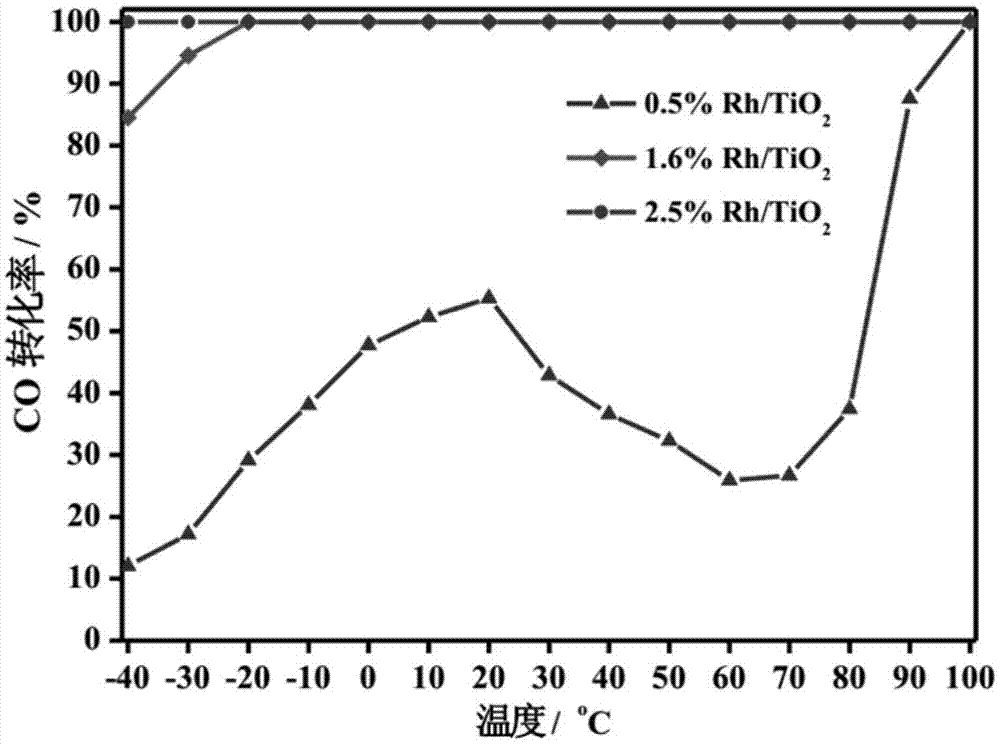

[0031] 1g mixed crystal phase titanium oxide (Degussa P25, 80% anatase and 20% rutile, the same below) carrier was ultrasonically dispersed in 100mL deionized water to form a suspension; take 8mL of 0.68mg / mL chlorination Rhodium solution, add 100mL deionized water to stir and dilute, and add dropwise to the carrier suspension under vigorous stirring, adjust the pH to 9.6, stir at 80℃ for 3h, stand for 1h, filter, wash with hot water, and oven at 80℃ Dry for 12h. After drying, the catalyst was calcined in the air at 400℃ for 4h to obtain 0.5wt.% Rh / TiO 2 catalyst.

Embodiment 2

[0033] Disperse 1g P25 carrier ultrasonically in 100mL deionized water to form a suspension; take 28mL of 0.68mg / mL rhodium chloride solution, add 100mL deionized water to stir and dilute, and add dropwise to the carrier suspension under vigorous stirring , Adjust the pH to 9.8, stir at 80°C for 3h, stand for 1h, filter, wash with hot water, and dry in an oven at 80°C for 12h. After drying, the catalyst was calcined in the air at 400℃ for 4 hours to obtain 1.6wt.% Rh / TiO 2 catalyst. Example 3:

Embodiment 3

[0034] Disperse 1g of P25 carrier ultrasonically in 100mL of deionized water to form a suspension; take 40mL of 0.68mg / mL rhodium chloride solution, add 100mL of deionized water, stir and dilute, and add dropwise to the carrier suspension under vigorous stirring , Adjust the pH to 9.4, stir at 80℃ for 3h, stand for 1h, filter, wash with hot water, and dry in an oven at 80℃ for 12h. After drying, the catalyst was calcined in the air at 400℃ for 4 hours to obtain 2.5wt.% Rh / TiO 2 catalyst. Example 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com