Nickel-cobalt compound nanowire with controllable composition, and preparation method and application thereof

A technology of nanowires and compounds, applied in the field of nickel-cobalt compound nanowires and its preparation, can solve the problems of unsatisfactory electrolytic water catalytic performance, high price, low solubility, etc., achieve good electrolytic water catalytic performance, low cost, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Specifically, the preparation method of the composition-controllable nickel-cobalt compound nanowire may include the following steps:

[0028] Step A, mixing nickel nitrate, cobalt nitrate and urea together in water, so that the concentration of nickel nitrate is 0.5~2.0 mmol / liter, the concentration of cobalt nitrate is 0.25~1.0 mmol / liter, and the concentration of urea is 5~10 mmol / L precursor mixed solution. In practical application, nickel nitrate, cobalt nitrate and urea may be added to water so that nickel nitrate, cobalt nitrate and urea are mixed together in water.

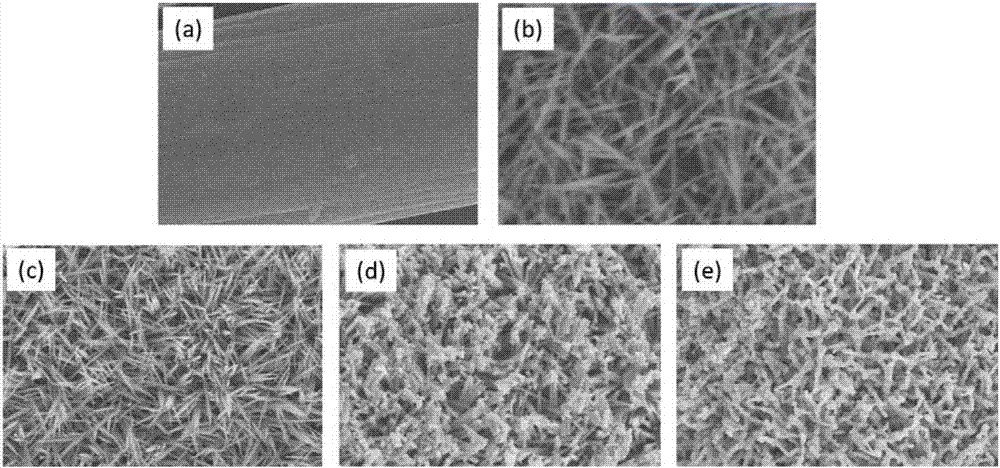

[0029] Step B, transferring the substrate and the precursor mixed solution to an autoclave, and reacting at 80-150°C for 200-400 minutes, so as to prepare NiCo on the substrate 2 (OH)(CO 3 ) 2Nanowires. In practical applications, the substrate is carbon fiber cloth (Carbon Fiber Cloth, CFC), nickel foam or titanium foil, but it is better to use carbon fiber cloth (for example: carbon fiber cloth...

Embodiment 1

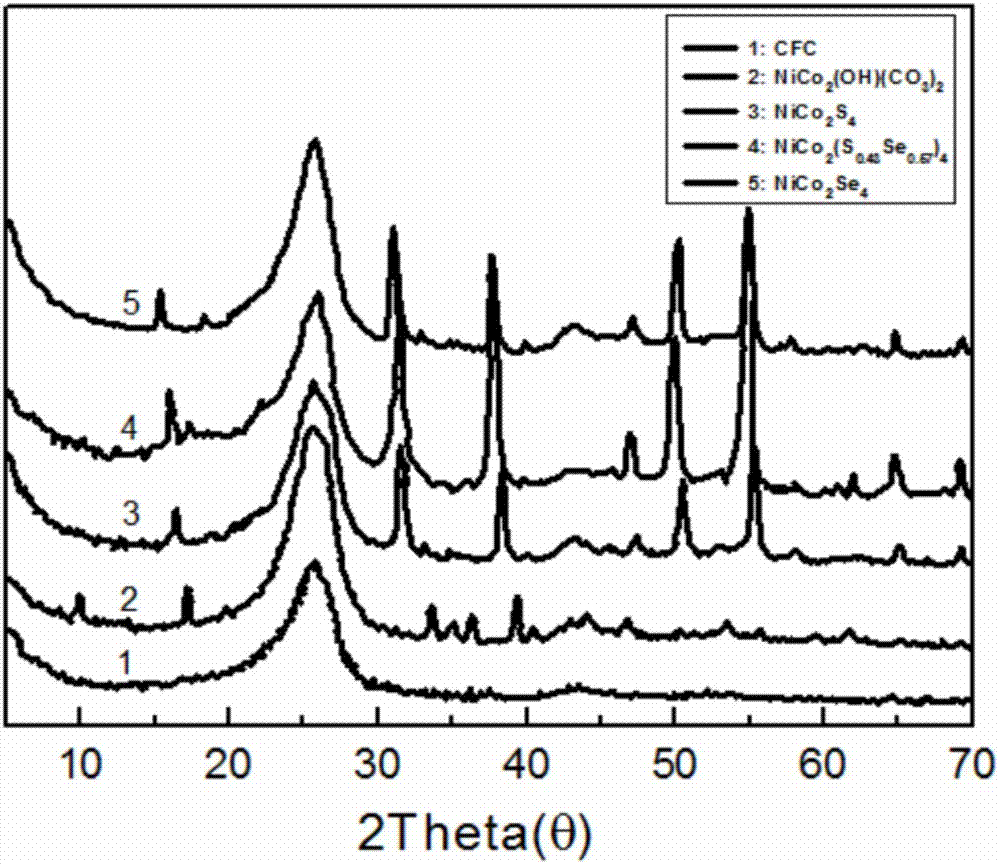

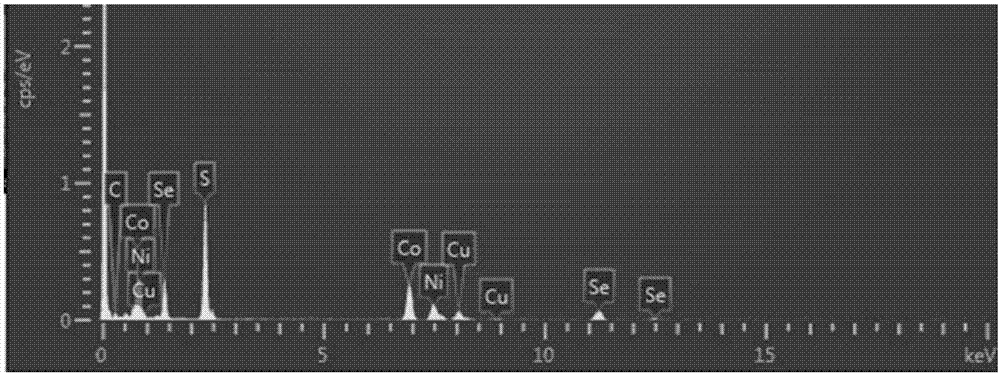

[0041] A NiCo based on CFC 2 (S 0.43 Se 0.57 ) 4 Nanowires, prepared by the following steps:

[0042] Step a1, adding nickel nitrate, cobalt nitrate and urea to the water and mixing to prepare a precursor with a nickel nitrate concentration of 1.5 mmol / L, a cobalt nitrate concentration of 0.75 mmol / L, and a urea concentration of 7.5 mmol / L mixture.

[0043] Step b1, using the CFC with a size of 1X3cm as the base, transfer the CFC and the precursor mixed solution described in step a1 to a 20-100mL autoclave, and react at 110°C for 300 minutes to obtain a CFC NiCo 2 (OH)(CO 3 ) 2 Nanowires.

[0044] Step c1, for NiCo based on CFC 2 (OH)(CO 3 ) 2 The nanowires are dried, and then according to the mixed solution of the precursor: the mass ratio of the mixed powder of sulfur powder and selenium powder=1:20, the NiCo based on CFC will be 2 (OH)(CO 3 ) 2 The nanowire is placed in a porcelain boat filled with 20mg sulfur powder and 20mg selenium powder mixed powder (that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com