Iron-nickel metal monatomic water electrolysis catalyst and preparation method thereof

A catalyst, water electrolysis technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problem of low activity, etc., achieve low cost, easy molding, excellent The effect of electrolytic water catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

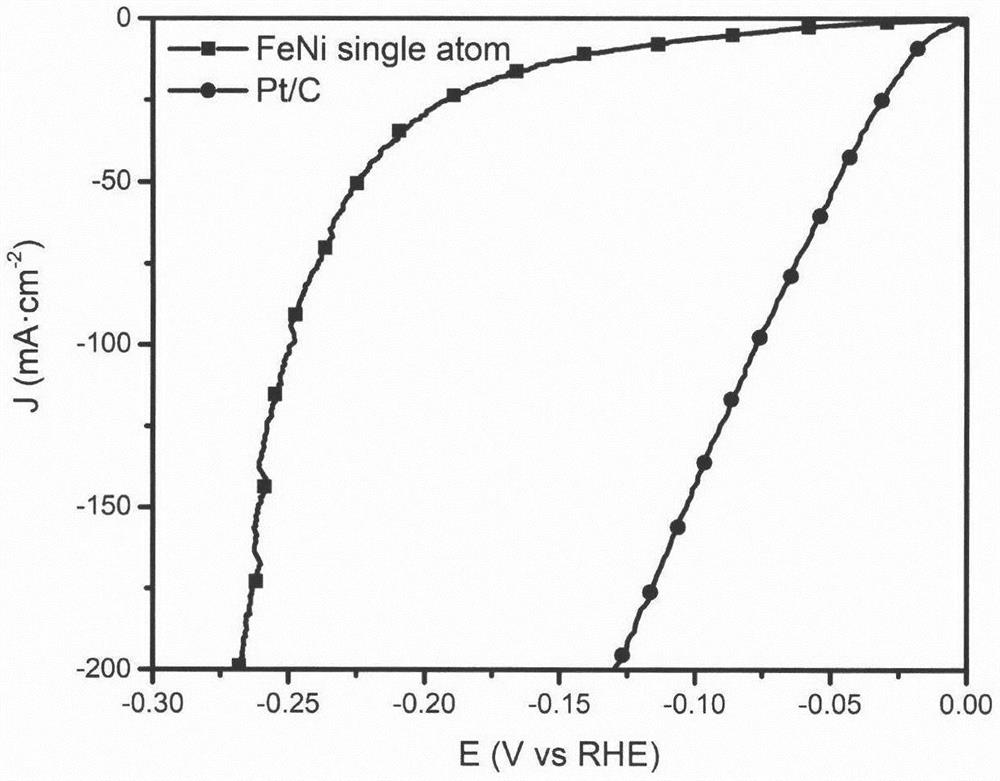

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

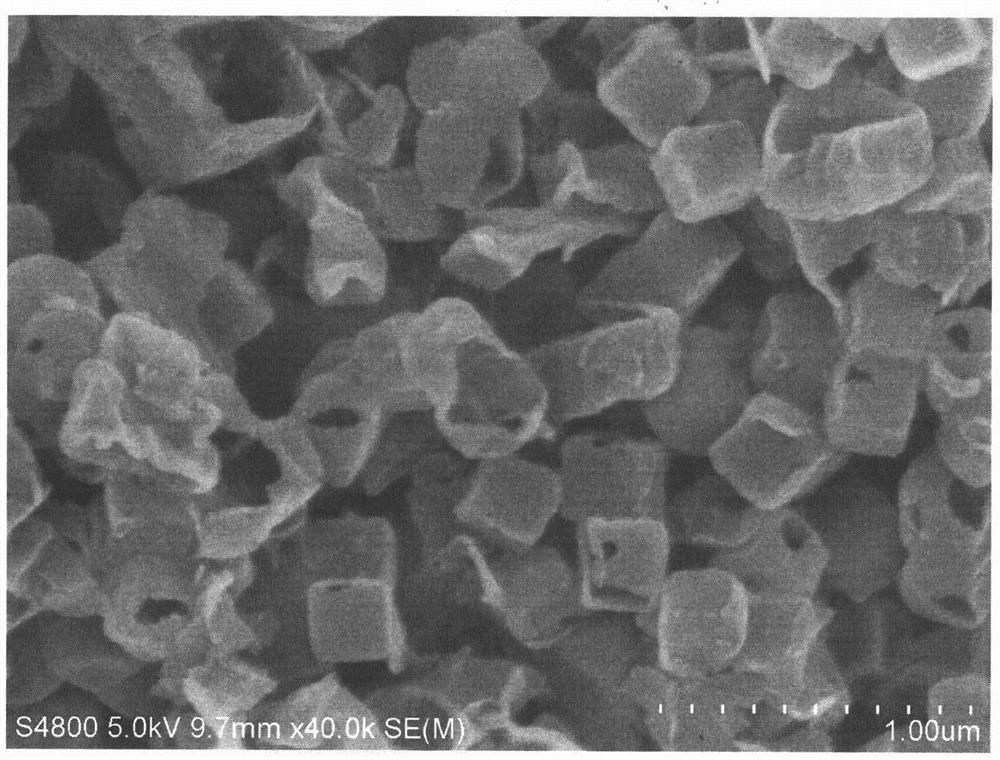

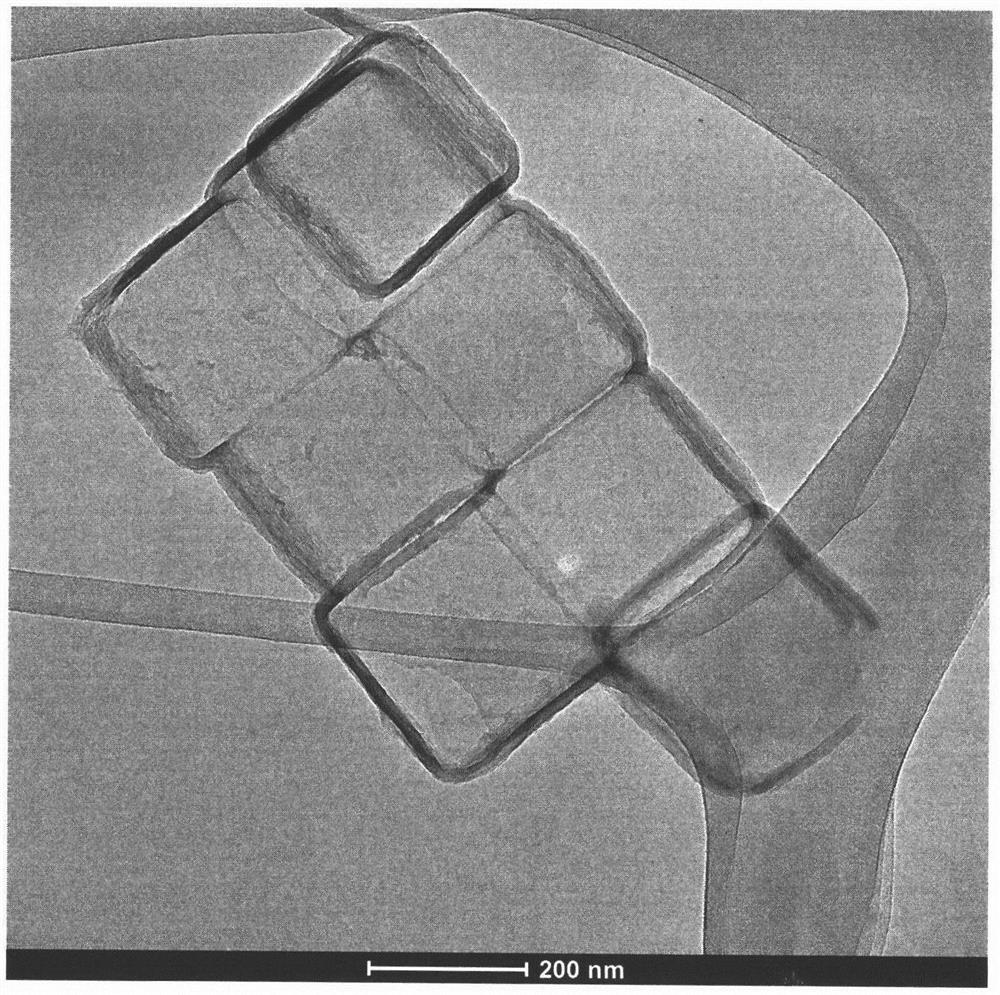

[0038] The preparation method of the FeNi metal single-atom electrolysis water catalyst of the present embodiment comprises the following steps:

[0039] 1) 0.87g nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and 1.32g sodium citrate are added in 100mL ultrapure water, and ultrasonic dispersion obtains solution A; 0.66g potassium cobaltcyanide (K 3 [Co(CN) 6 ]) was added into 100mL ultrapure water, ultrasonically dispersed to obtain solution B; solution A and solution B were mixed, magnetically stirred for 10min, then left at room temperature for 24h, centrifuged, and the solid was washed 3 times with ultrapure water and ethanol, Metal-organic frameworks (FeNi-MOFs) were obtained by vacuum drying overnight at 60 °C in a vacuum oven.

[0040] 2) Add 330 mg of the metal-organic frameworks (FeNi-MOFs) prepared in step 1) and 166.7 mg of dopamine into the Tris base buffer solution, and react with magnetic stirring for one day, then centrifuge, wash the solid with water, and...

Embodiment 2

[0045] The preparation method of the FeNi metal single-atom electrolysis water catalyst of the present embodiment comprises the following steps:

[0046]1) 0.87g nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 (0) and 1.329g sodium citrate are added in 80mL ultrapure water, and ultrasonic dispersion obtains solution A; 0.5g potassium ferricyanide (K 3 [Fe(CN) 6 ]) was added to 50mL ultrapure water, ultrasonically dispersed for 10min, and completely dissolved to obtain solution B; solution A and solution B were mixed, stirred on a magnetic stirrer, and then left to stand at room temperature for 24h, centrifuged, and used for solid The metal-organic frameworks (FeNi-MOFs) were prepared by washing with ultrapure water and ethanol three times each, and drying in a vacuum oven at 50 °C for one day.

[0047] 2) Annealing the product obtained in step 4) at 800° C. under an argon atmosphere to obtain a FeNi single-atom electrolytic water catalyst.

Embodiment 3

[0049] The preparation method of the FeNi metal single-atom electrolysis water catalyst of the present embodiment comprises the following steps:

[0050] 1) 1.17g nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and 1.75g sodium citrate are added in 105mL ultrapure water, ultrasonic dispersion obtains solution A; 1.08g potassium ferricyanide (K 3 [Fe(CN) 6 ]) was added into 80mL ultrapure water, ultrasonically dispersed to obtain solution B; solution A and solution B were mixed, stirred on a magnetic stirrer, then left at room temperature for 24 hours, centrifuged, and the solid was washed with ultrapure water and ethanol 3 times, and dried overnight at 55°C in a vacuum oven to obtain metal-organic frameworks (FeNi-MOFs).

[0051] 2) Place the FeNi-MOF / PDA nanocube prepared in step 2) in an ammonia atmosphere, and anneal at 500°C for 2 hours to obtain a hollow nitrogen-doped carbon nanocube (FeNi-NP / NC).

[0052] 3) Add the nitrogen-doped carbon nanocubes prepared in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com