Nickel manganese selenide heterojunction electrocatalyst as well as preparation method and application thereof

An electrocatalyst, nickel manganese oxide technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of cost and natural scarcity hindering application, hindering the development of electrolytic water hydrogen production, short service life, etc., to achieve good electrolysis. Water catalytic performance, excellent electrochemical activity, and the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

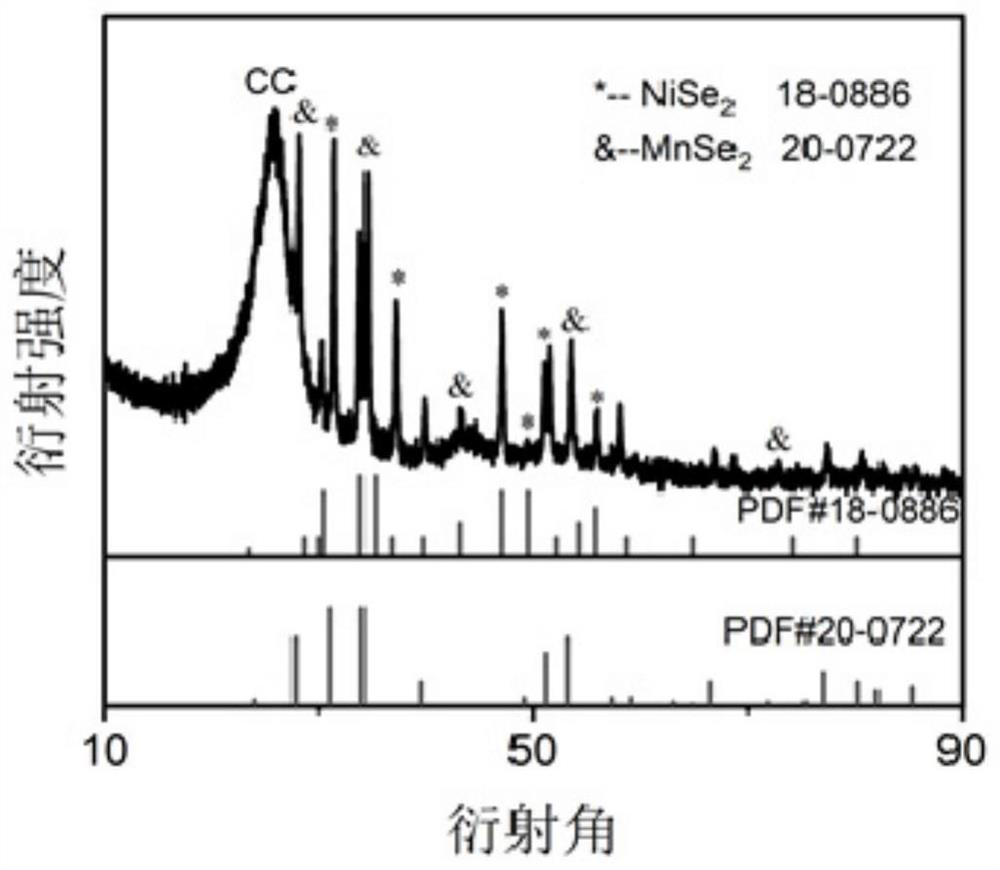

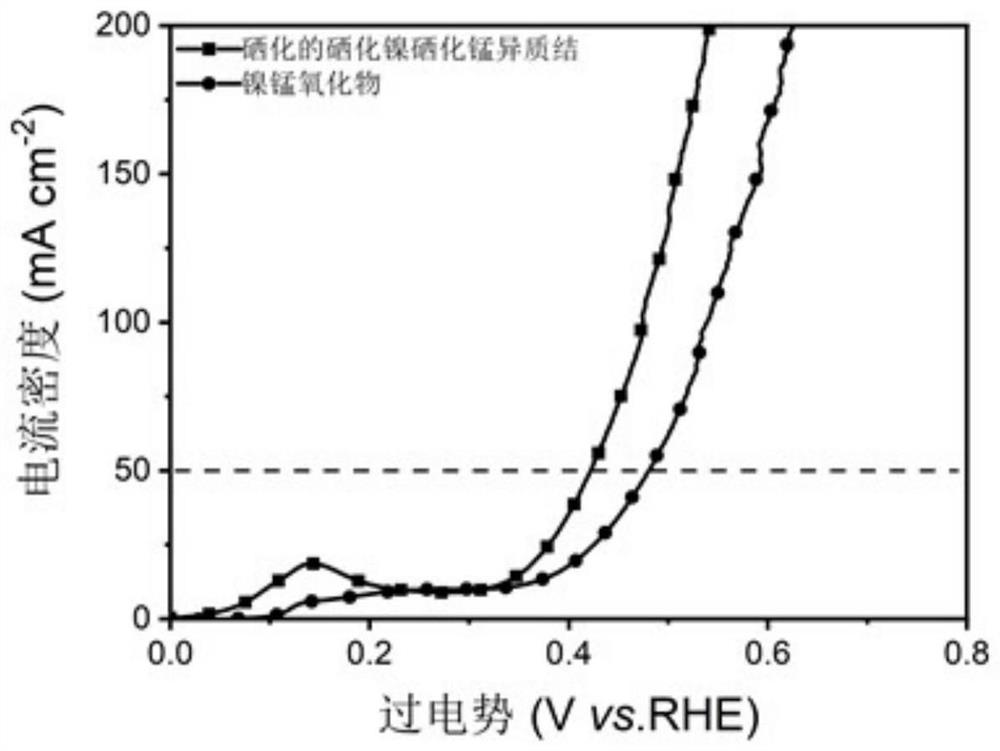

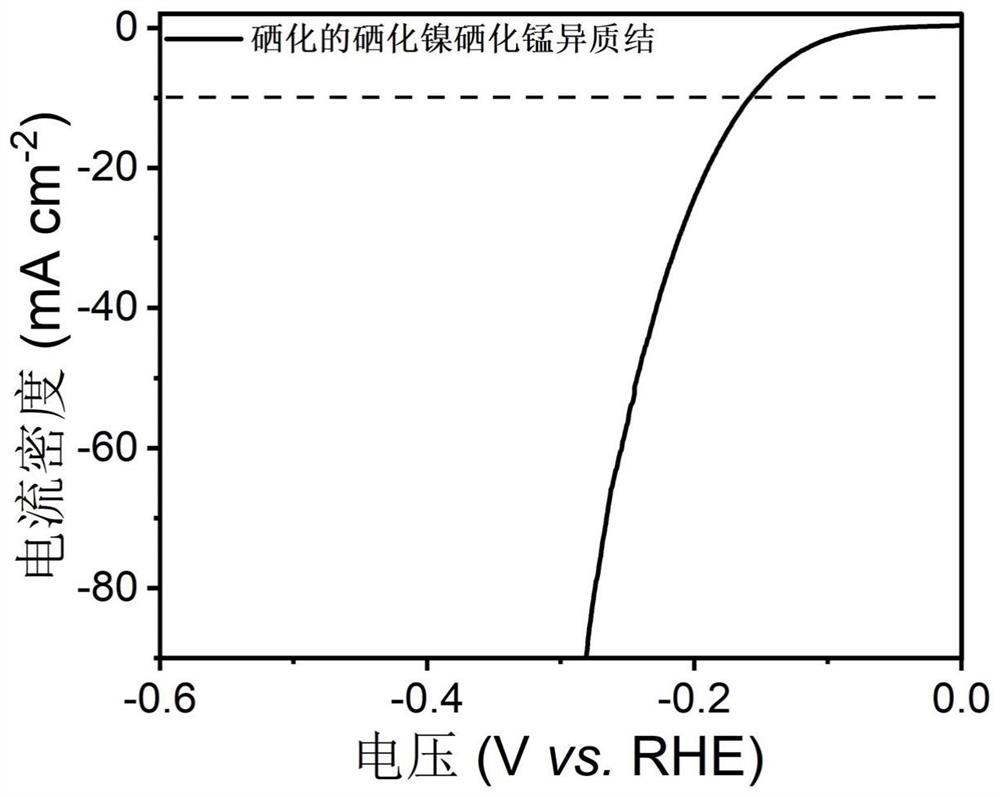

[0029] A nickel manganese selenide heterojunction electrocatalyst, the specific steps of its preparation method are as follows:

[0030] Dissolve 0.08mol of nickel chloride, 0.08mol of manganese nitrate, and 0.003mol of potassium persulfate in 300mL of deionized water, and stir for 10 minutes to obtain a mixed solution. 2 Carbon cloth (pre-placed in deionized water and ultrasonically treated to remove surface grease and impurities) was added to the mixed solution, stirred for 3 minutes, and then 4 mL of ammonia solution with a pH value of 8 was added dropwise to the solution at 15°C while stirring, and the dropwise addition was completed. Take it out after standing for 20min, put it into a tube furnace after drying, heat up to 300°C from room temperature with a heating rate of 5°C / min, and keep it warm for 30min to obtain a carbon cloth (500mg ), the prepared carbon cloth coated with layered nanosheets of nickel-manganese oxide was washed with deionized water and alcohol for 3...

Embodiment 2

[0037] A nickel manganese selenide heterojunction electrocatalyst, the specific steps of its preparation method are as follows:

[0038] Dissolve 0.08mol nickel chloride, 0.16mol manganese nitrate, and 0.003mol potassium persulfate in 300mL deionized water, stir for 10 minutes to obtain a mixed solution, and use ultrasonic treatment to remove 9cm of surface grease and impurities. 2Add carbon cloth into the mixed solution, stir for 3 minutes, then add 4 mL of ammonia solution with a pH value of 9 to the solution dropwise while stirring at 15°C, let it stand for 20 minutes after the addition, take it out, dry it and put it in a tube furnace, Raise the temperature from room temperature to 350°C at a rate of 5°C / min, and keep it warm for 30min to obtain a carbon cloth (700mg) coated with nickel-manganese oxide layered nanosheets, and wrap the prepared nickel-manganese oxide layered nanosheets The covered carbon cloth is washed with deionized water and alcohol for 3-5 times, put in...

Embodiment 3

[0040] A nickel manganese selenide heterojunction electrocatalyst, the specific steps of its preparation method are as follows:

[0041] Dissolve 0.08mol nickel chloride, 0.32mol manganese nitrate, and 0.003mol potassium persulfate in 300mL deionized water, stir for 10 minutes to obtain a mixed solution, and use ultrasonic treatment to remove 9cm of surface grease and impurities. 2 Carbon cloth was added to the mixed solution, stirred for 3 minutes, and then 4 mL of ammonia solution with a pH value of 8 was added dropwise to the solution while stirring at 15°C. Raise the temperature from room temperature to 400°C at a rate of 5°C / min, and keep it warm for 30min to obtain a carbon cloth (600mg) coated with nickel-manganese oxide layered nanosheets, and wrap the prepared nickel-manganese oxide layered nanosheets The covered carbon cloth is washed with deionized water and alcohol for 3-5 times, put into a blast drying oven at 60°C for drying, and then placed in the downstream of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com