Preparation method of plastic-biomass active carbon and prepared active carbon thereof

A biomass and activated carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of increasing the preparation cost of shaped activated carbon, loss of specific surface area of shaped activated carbon, and affecting adsorption and desorption performance, etc., to achieve large market applications Prospect, avoidance of loss of pore structure, effect of large iodine adsorption value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

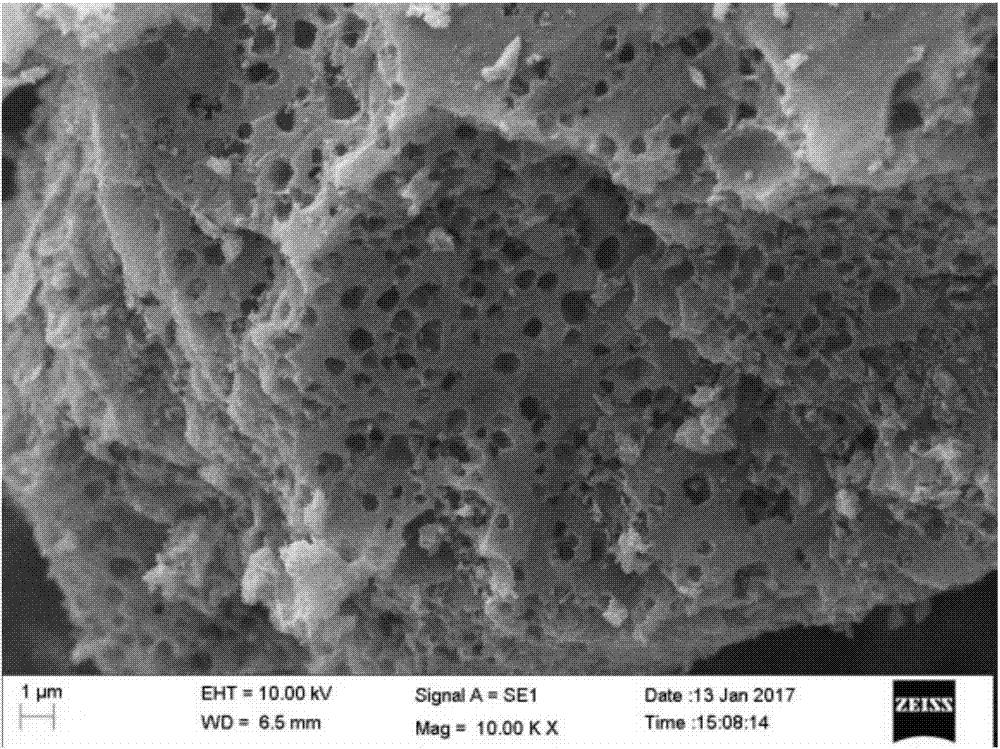

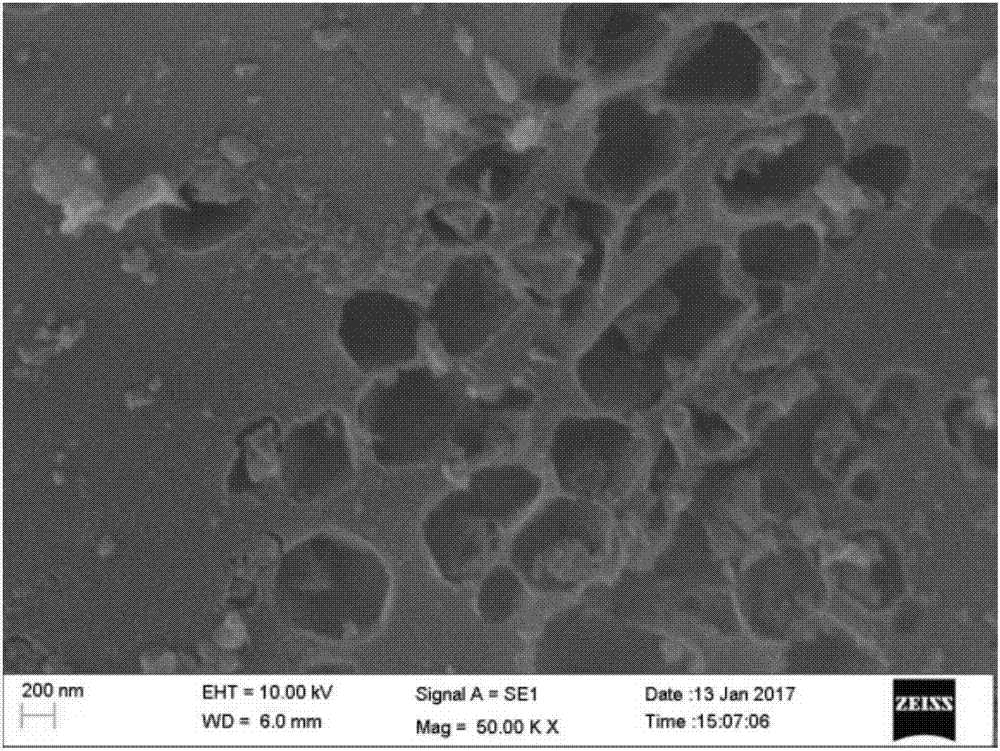

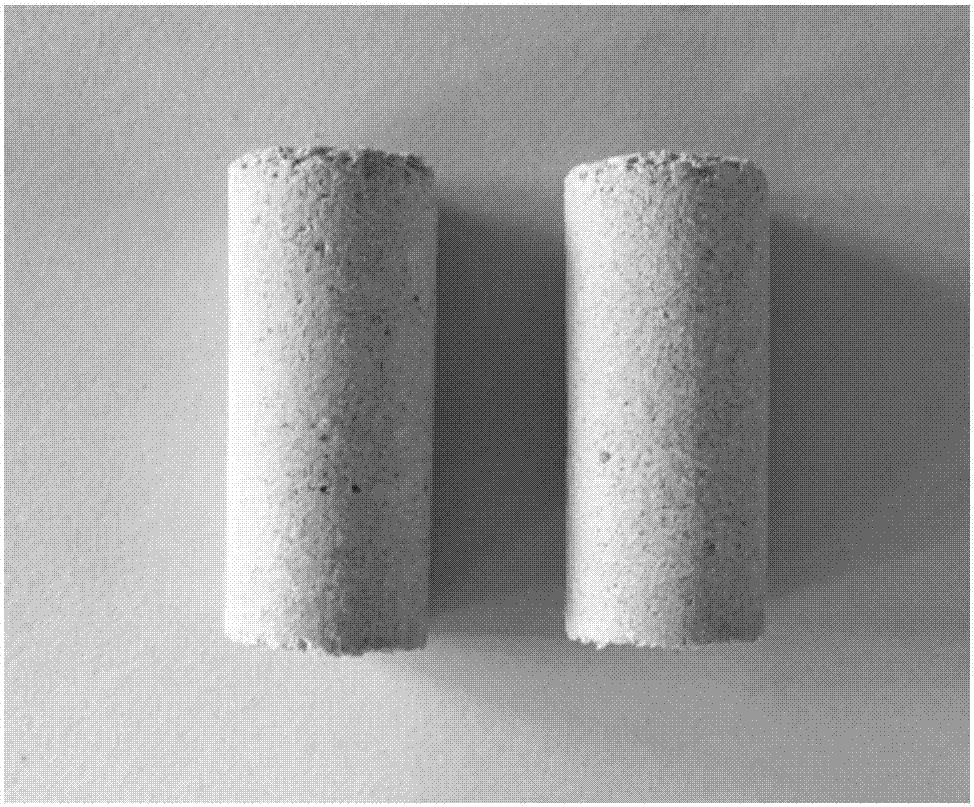

[0036] A kind of preparation method of plastic-biomass activated carbon is characterized in that comprising the following steps:

[0037] Step 1, the raw materials are pulverized and mixed, and recycled polypropylene plastic, wood sawdust and anhydrous K 2 CO 3 Grind the raw materials to 35 mesh respectively, and then stir and mix for 2 minutes; the mixing rate of the mixture is ω=5%, the ratio of salt to material γ=1.0, and the water content is 15%; the mixing of solid activator and raw materials in the raw material crushing and screening mixing process It is dry mixing at room temperature and does not require long-term solution immersion. During the processing, storage and use of plastics, due to the combined effects of internal and external factors, their performance gradually deteriorates, so that they eventually lose their use value. Plastic aging is an irreversible change that is common to materials. However, waste aging plastics are highly brittle, and the degree of ...

Embodiment 2

[0051] Step 1, the raw materials are pulverized and mixed, and recycled polypropylene plastic, wood sawdust and anhydrous K 2 CO 3 Grind the raw materials to 40 mesh respectively, and then stir and mix for 2 minutes; the mixing ratio of the mixture is ω=30%, the ratio of salt to material γ=2.5, and the water content is 25%; the mixing of solid activator and raw materials in the process of crushing, screening and mixing of raw materials It is dry mixing at room temperature and does not require long-term solution immersion. During the processing, storage and use of plastics, due to the combined effects of internal and external factors, their performance gradually deteriorates, so that they eventually lose their use value. Plastic aging is an irreversible change that is common to materials. However, waste aging plastics are highly brittle, and the degree of pulverization after crushing is higher. Directly mixing recycled plastics into biomass materials to make activated carbon ...

Embodiment 3

[0066] Step 1, the raw materials are pulverized and mixed, and recycled polypropylene plastic, wood sawdust and anhydrous K 2 CO 3 Grind the raw materials to 40 mesh respectively, and then stir and mix for 2 minutes; the mixing rate of the mixture is ω=5%, the ratio of salt to material γ=2.0, and the water content is 20%; the mixing of solid activator and raw materials in the raw material crushing and screening mixing process It is dry mixing at room temperature and does not require long-term solution immersion. During the processing, storage and use of plastics, due to the combined effects of internal and external factors, their performance gradually deteriorates, so that they eventually lose their use value. Plastic aging is an irreversible change that is common to materials. However, waste aging plastics are highly brittle, and the degree of pulverization after crushing is higher. Directly mixing recycled plastics into biomass materials to make activated carbon can recycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com