Preparation method of high-purity daptomycin lactone hydrolysate

A daptomycin and hydrolyzate technology, applied in the direction of peptides, etc., can solve the problems of daptomycin resistance, disrupting translocation, affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

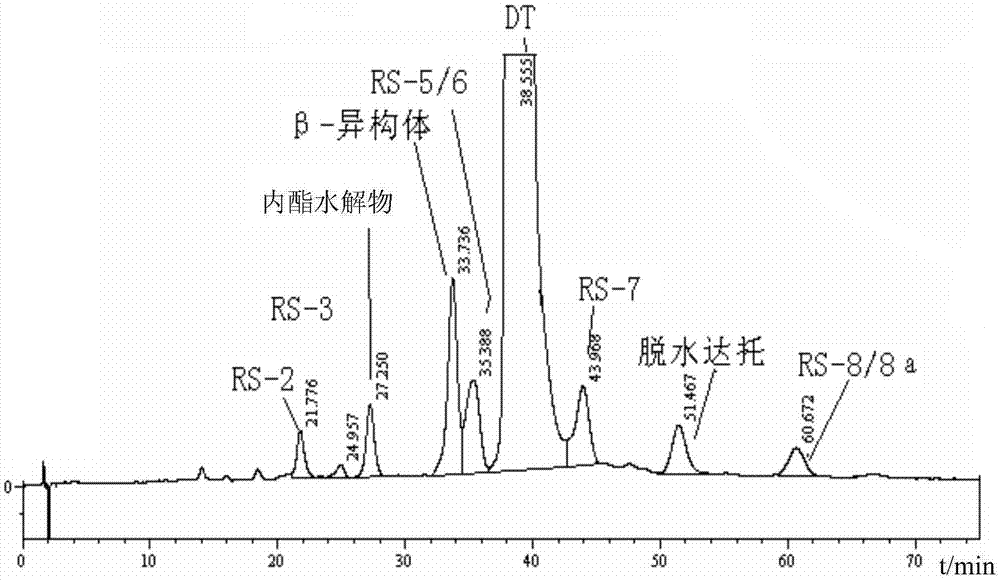

Image

Examples

Embodiment 1

[0026] After filtering the daptomycin fermentation broth, the filtrate is chromatographed on FPDA13 resin, and the column is washed with 0.03N sodium chloride, 0.06N sodium acetate, acetic acid to adjust the pH 6.5-7.0 solution 2BV, 0.3N sodium chloride, 0.06N acetic acid Sodium and acetic acid adjust the pH 6.5-7.0 solution to elute, collect the chromatographic solution of daptomycin lactone hydrolysate with chromatographic purity greater than 10%, adjust the pH to 2.5, and store at a constant temperature of 20°C for 24 hours to obtain a chromatographic purity of 20% Daptomycin lactone hydrolysate solution.

[0027] The daptomycin lactone hydrolysate solution was separated and purified by preparative chromatography (mobile phase: methanol:0.01% trifluoroacetic acid=25:75), and followed by high-performance liquid phase detection (detection conditions are the same as the European patent "PROCESS FOR THE PURIFICATION OFDAPTOMYCIN" (EP 1 586 580 A2) discloses the same method), colle...

Embodiment 2

[0030] After filtering the daptomycin fermentation broth, the filtrate is chromatographed on FPDA13 resin, 0.03N sodium chloride, 0.06N sodium acetate, acetic acid to adjust pH 6.5-7.0 solution 2BV to wash the column, 0.3N sodium chloride, 0.06N sodium acetate , Acetic acid adjusts the pH 6.5-7.0 solution to elute, collect the chromatographic solution of daptomycin lactone hydrolysate with chromatographic purity greater than 10%, adjust pH 3, store at 20°C for 24h, obtain daptomyces with 25% chromatographic purity Hydrolysate solution of prime lactone.

[0031] The daptomycin lactone hydrolysate solution was separated and purified by preparative chromatography (mobile phase: methanol:0.01% trifluoroacetic acid=25:75), and followed by high-performance liquid phase detection (detection conditions are the same as the European patent "PROCESS FOR THE PURIFICATION OFDAPTOMYCIN" (EP 1 586 580 A2) discloses the same method), collect chromatographic purity> 90% daptomycin lactone hydroly...

Embodiment 3

[0034] After filtering the daptomycin fermentation broth, the filtrate is chromatographed on FPDA13 resin, 0.03N sodium chloride, 0.06N sodium acetate, acetic acid to adjust pH 6.5-7.0 solution 2BV to wash the column, 0.3N sodium chloride, 0.06N sodium acetate , Acetic acid adjusts the pH 6.5-7.0 solution to elute, collect the chromatographic solution of daptomycin lactone hydrolysate with chromatographic purity greater than 10%, adjust the pH 4, store at 20°C for 24 hours, obtain daptomyces with chromatographic purity 37% Hydrolysate solution of prime lactone.

[0035] The daptomycin lactone hydrolysate solution was separated and purified by preparative chromatography (mobile phase: methanol:0.01% trifluoroacetic acid=25:75), and followed by high-performance liquid phase detection (detection conditions are the same as the European patent "PROCESS FOR THE PURIFICATION OFDAPTOMYCIN" (EP 1 586 580 A2) discloses the same method), collect chromatographic purity> 90% daptomycin lacton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com