A processing auxiliary agent having compatibility-enabling and coupling functions and a preparing method thereof

A technology of processing aids and functions, which is applied in the field of processing aids and preparations with compatibility and coupling functions, can solve the problems of low grafting rate of oligomers, uncontrollable problems, etc., to improve surface gloss performance and reduce processing Energy consumption, effect of reducing melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

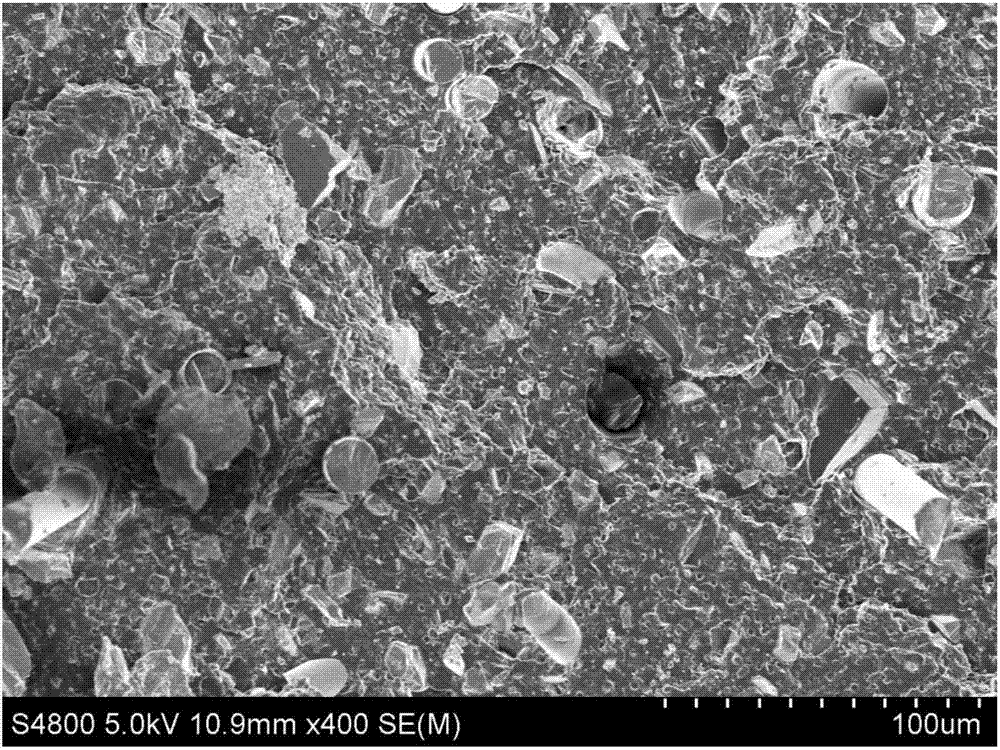

Image

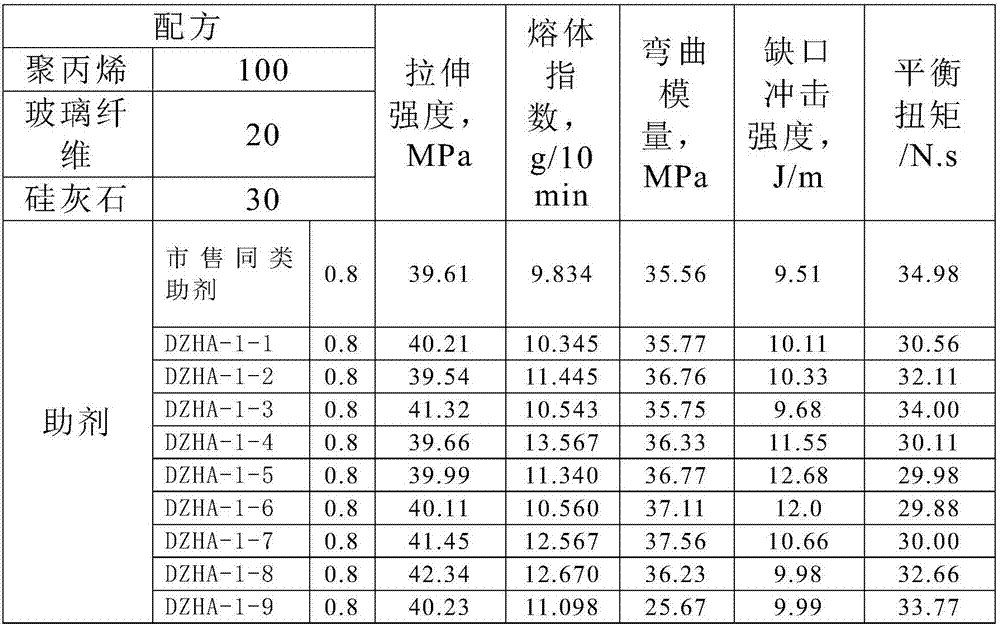

Examples

Embodiment 1

[0027] Get 65 grams of polypropylene wax and 20 grams of polyethylene wax and place in the 250ml four-necked flask of condenser, stirrer, equal pressure funnel and thermometer, place the four-necked flask in the electric heater with program temperature control. Take 5 grams of maleic anhydride, 15 grams of vinyltrimethoxysilane, and 1 gram of dibenzoyl peroxide, mix them uniformly, and place them in an equal-pressure funnel. The four-necked flask was heated to completely melt the polypropylene wax and the polyethylene wax, and the temperature in the four-necked flask was controlled at 180°C. Turn on the cooling water in the condensing tube, turn on the stirrer, open the equal pressure funnel valve, start to drop the mixture in the equal pressure funnel, and the speed of dropping is controlled at 150ml / hour. After the dropwise addition, the temperature in the four-neck flask was controlled at 200° C., and after 3 hours of reaction, the cooling water in the condenser tube was tu...

Embodiment 2

[0029] Get 85 grams of polypropylene wax and 10 grams of polyethylene wax and place in the 250ml four-necked flask of condenser, agitator, equal pressure funnel and thermometer, and place the four-necked flask in the electric heater with programmed temperature control. Take 10 grams of maleic anhydride, 5 grams of vinyltrimethoxysilane, and 2 grams of dibenzoyl peroxide, mix them uniformly, and place them in an equal-pressure funnel. The four-necked flask was heated to completely melt the polypropylene wax and the polyethylene wax, and the temperature in the four-necked flask was controlled at 170°C. Turn on the cooling water in the condensing tube, turn on the stirrer, open the valve of the equal pressure funnel, start to drop the mixture in the equal pressure funnel, and the speed of dropping is controlled at 200ml / hour. After the dropwise addition, the temperature in the four-neck flask was controlled at 200° C., and after 3 hours of reaction, the cooling water in the conde...

Embodiment 3

[0031]Get 65 grams of polypropylene wax and 20 grams of semi-refined wax and place in the 250ml four-necked flask of condenser, agitator, equal pressure funnel and thermometer, and place the four-necked flask in an electric heater with programmed temperature control. Take 5 grams of methyl acrylate, 15 grams of vinyltriethoxysilane, and 1 gram of dicumyl peroxide, mix them uniformly, and place them in an equal-pressure funnel. The four-necked flask is heated to completely melt the polypropylene wax and the semi-refined wax, and the temperature in the four-necked flask is controlled at 180°C. Turn on the cooling water in the condensing tube, turn on the stirrer, open the equal pressure funnel valve, start to drop the mixture in the equal pressure funnel, and the speed of dropping is controlled at 150ml / hour. After the dropwise addition, the temperature in the four-neck flask was controlled at 200° C., and after 3 hours of reaction, the cooling water in the condenser tube was tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com