Shock-insulating polyurethane elastomer material composition and preparation method thereof

A technology of polyurethane elastomer and material composition, which is applied in the field of two-component room temperature curing polyurethane elastomer composition and its preparation, and can solve the problems of heat insulation, sound insulation, unsatisfactory shock absorption, and unreported shock isolation performance, etc. , to achieve great economic significance, improve seismic isolation performance, and improve the effect of dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

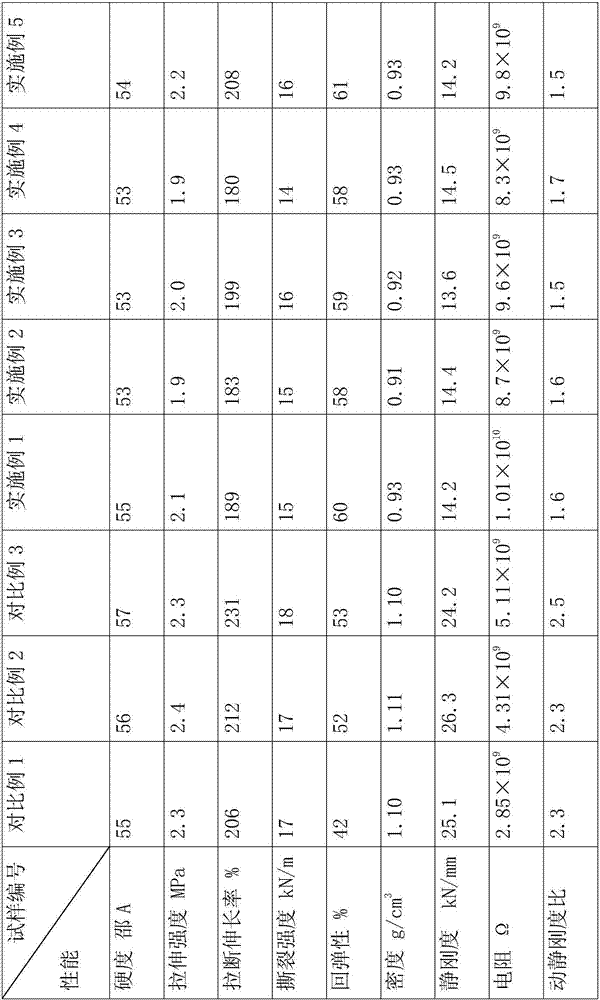

Embodiment 1

[0053] A component: polyol component: obtain according to following preparation method: by weight, the polypropylene oxide ether polyol (GEP-3600) 60 of molecular weight 6000, the graft polyether polyol (GPOP-3600) that molecular weight is 6000 36 / 28) 40, chain extender E-300, 14.5, chain extender 1,4-BDO6.4, ultraviolet absorber UV-P 0.5, catalyst dibutyltin dilaurate 0.05, catalyst A33 0.1, barium sulfate 15, Organic hollow microspheres WU-150W 0.5, antioxidant 1010, 0.5, defoamer BYK-066N0.6, mixed and stirred at 100±10°C, vacuum degree -0.1MPa, and vacuumed.

[0054] Component B: Isocyanate component: Obtained according to the following preparation method: In weight percentage, PM-200 and MDI-50 are mixed according to the mass ratio of 1:1

[0055] The isocyanate component and the polyol component are mixed and reacted with a chain extension coefficient of 0.90. The mixing temperature and curing temperature are at room temperature, and the gelation takes 40 minutes. The sa...

Embodiment 2

[0064] A component: polyol component: obtain according to following preparation method: by weight, the polypropylene oxide ether polyol (GEP-3600)70 of molecular weight 6000, the graft polyether polyol (GPOP-3600) that molecular weight is 6000 36 / 28) 30, chain extender E-30014.5, chain extender 1,4-BDO 6.4, ultraviolet absorber UV-P 0.5, catalyst dibutyltin dilaurate 0.05, catalyst A33 0.1, barium sulfate 15, organic hollow micro Ball WU-150W 0.8, antioxidant 1010 0.5, defoamer BYK-066N 0.6, mix and stir at 100±10°C, vacuum degree -0.1MPa, and vacuumize.

[0065] Component B: Isocyanate component: obtained according to the following preparation method: in weight percentage, PM-200 and MDI-50 are mixed according to the mass ratio of 60:40

[0066] The isocyanate component and the polyol component were mixed and reacted with a chain extension coefficient ratio of 0.90. The mixing temperature and curing temperature were at room temperature, gelled in 40 minutes, demolded after 24...

Embodiment 3

[0068] A component: polyol component: obtain according to following preparation method: by weight, the polypropylene oxide ether polyol (GEP-3600) 60 of molecular weight 6000, the graft polyether polyol (GPOP-3600) that molecular weight is 6000 36 / 28)40, chain extender E-30014.5, chain extender 1,4-BDO6.4, ultraviolet absorber UV-P 0.5, catalyst dibutyltin dilaurate 0.05, catalyst A33 0.1, barium sulfate 15, organic hollow Microsphere WU-150W 0.5, antioxidant 1010 0.5, defoamer BYK-066N 0.6, mix and stir at 100±10°C, vacuum degree -0.1MPa, and vacuumize.

[0069] Component B: isocyanate component: obtained according to the following preparation method: in weight percentage, 57% of polypropylene oxide ether polyol (Tdiol-1000 and Tdiol-2000) with 2 functionalities and molecular weight of 1000-2000, diphenyl Methane diisocyanate (MDI-100) 43%, react at 80°C for 2-3 hours to obtain a prepolymer with an isocyanate content of 13%.

[0070] The isocyanate component and the polyol c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com