A kind of preparation method of hollow spherical titanium dioxide modified polyacrylate emulsion

A technology of polyacrylate emulsion and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of little contribution to thermal insulation performance and anti-ultraviolet performance, and improve thermal insulation performance, anti-ultraviolet performance and light reflectance Improvement, the effect of elongation at break improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

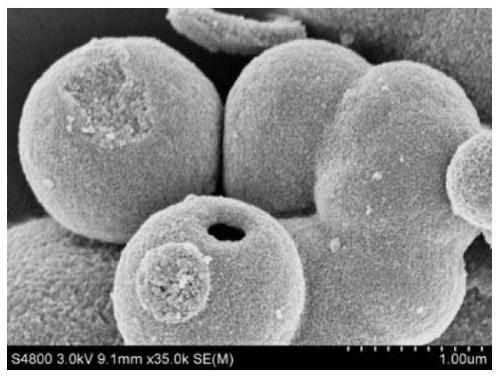

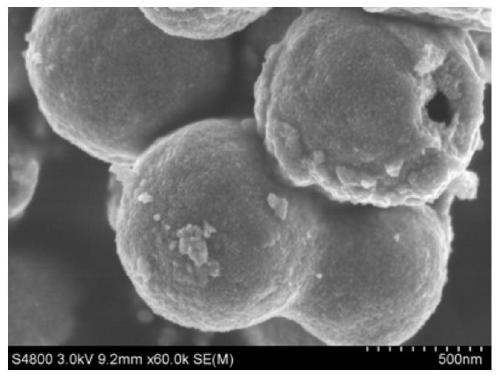

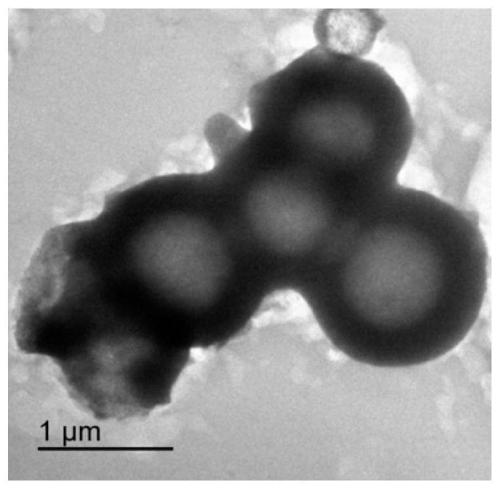

[0026] Disperse 0.1g of tetrabutyl titanate in 35mL of absolute ethanol, stir at a speed of 300rpm for 30min to obtain a suspension of tetrabutyl titanate in absolute ethanol, and then transfer it to a 100mL polytetrafluoroethylene reactor. Raise the temperature to 220°C, react for 2h, cool to room temperature, wash by centrifugation, dry in an oven at 60°C for 8h, and then calcinate in a muffle furnace at 500°C for 5h to obtain hollow spherical titanium dioxide.

[0027] Ultrasonic dispersion of 0.161g of hollow spherical titanium dioxide (the power of ultrasonic dispersion is 500W, and the time is 10min) in 20g of deionized water, and then added to 20g of polyacrylate emulsion, mixed evenly and stirred at 75°C and 300rpm for 8h, the obtained product It is hollow spherical titanium dioxide modified polyacrylate emulsion.

[0028] Wherein, the solid content of the hollow spherical titanium dioxide modified polyacrylate emulsion is 40%.

Embodiment 2

[0030] Disperse 0.3g of tetrabutyl titanate in 35mL of absolute ethanol, and stir at 450rpm for 1h to obtain a suspension of tetrabutyl titanate in absolute ethanol, which is then transferred to a 100mL polytetrafluoroethylene reactor. The temperature was raised to 220°C, the reaction time was 3h, cooled to room temperature, washed by centrifugation, dried in an oven at 60°C for 12h, and then calcined in a muffle furnace at 500°C for 5h to obtain hollow spherical titanium oxide.

[0031] Add 0.196g of hollow spherical titanium dioxide into 25g of polyacrylate emulsion in 20g of deionized water by ultrasonic dispersion (the power of ultrasonic dispersion is 200W, and the time is 20min). It is a hollow spherical titanium dioxide modified polyacrylate emulsion.

[0032] Wherein, the solid content of the hollow spherical titanium dioxide modified polyacrylate emulsion is 40%.

Embodiment 3

[0034] Disperse 0.5g of tetrabutyl titanate in 35mL of absolute ethanol, stir at 450rpm for 2h to obtain a suspension of tetrabutyl titanate in absolute ethanol, and then transfer it to a 100mL polytetrafluoroethylene reactor. The temperature was raised to 200°C, and the reaction time was 4h. After cooling to room temperature, it was centrifuged and washed, dried in an oven at 60°C for 12h, and then calcined in a muffle furnace at 550°C for 4h to obtain hollow spherical titanium dioxide.

[0035] Add 0.238g of hollow spherical titanium dioxide into 30g of polyacrylate emulsion in 20g of deionized water by ultrasonic dispersion (the power of ultrasonic dispersion is 300W, and the time is 18min). It is a hollow spherical titanium dioxide modified polyacrylate emulsion.

[0036] Wherein, the solid content of the hollow spherical titanium dioxide modified polyacrylate emulsion is 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com