In-furnace oil tar self-stripping type organic solid fuel gasification device and method

A technology of fuel gasification and organic solids, which is applied in the gasification process, petroleum industry, chemical industry, etc., can solve the problems of easy precipitation and blockage of pipelines, difficult treatment, environmental pollution, etc., and achieves increased residence time, simple and compact structure, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

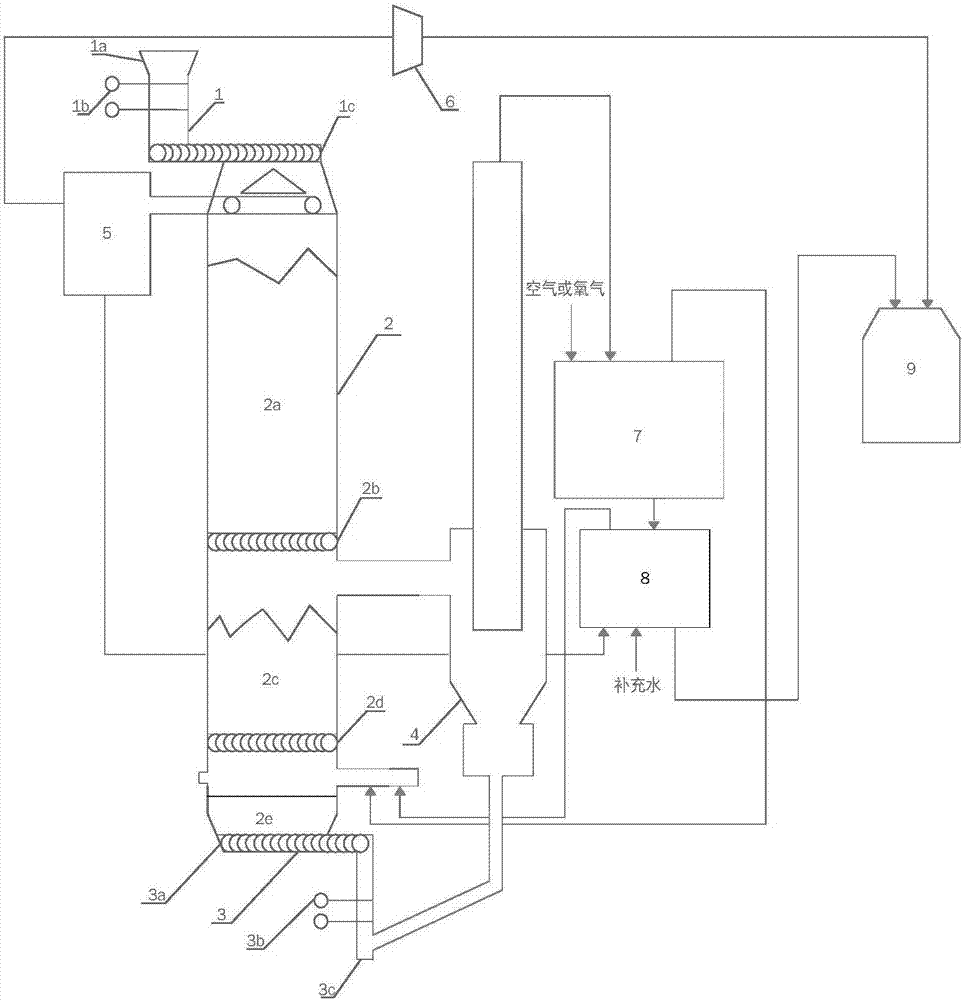

[0033] An in-furnace self-detarring type organic solid fuel gasification device and method, the device includes a feeding device 1, a gasification device 2, a gasification gas fly ash cyclone separation device or a fly ash separation and filtration device 4, a condensation device 5, Condensed water evaporation device 7, gasification medium preheating device 8, ash discharge device 3 and air storage tank 9; the feeding device 1 includes a feeding port 1a, a two-stage sealed feeding valve 1b and a screw feeder 1c , the outlet of the feed port 1a is connected to the inlet of the screw feeder 1c, and the outlet of the screw feeder 1c is connected to the top of the furnace of the gasification device 2; The gasification combustion section 2c and the ash section 2e, the gasification agent inlet is arranged between the gasification combustion section 2c and the ash section 2e; the ash discharge device 3 includes a screw discharger 3a, a two-stage sealed discharge valve 3b and the blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com