A method for preparing rice wine with high oxidation resistance by screw extrusion, enzymatic method and ultrasonic aging technology

A screw extrusion and oxidizing technology, which is applied in the field of rice wine fermentation technology, can solve the problems affecting the production and capital operation of the winery, the long natural aging storage period, and the large area of the pottery ancient warehouse, so as to ensure high oxidation resistance and promote Effect of mechanized process and poor wine quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

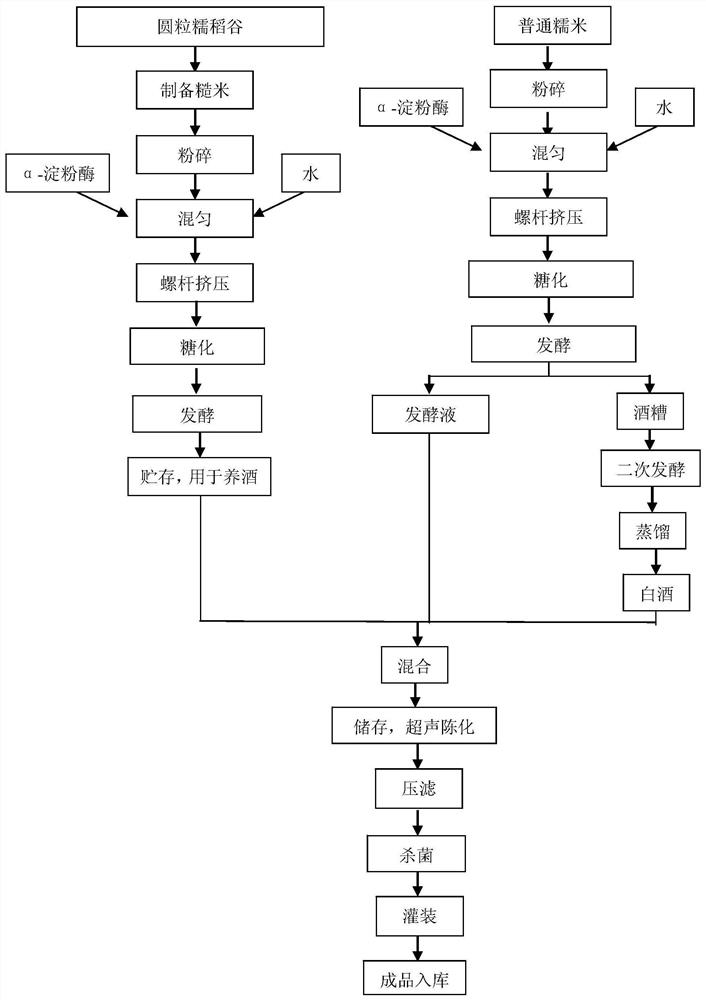

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of brown rice wine body: select round grain glutinous rice grains, shell to obtain brown rice, sieve brown rice flour after brown rice milling, weigh 100kg brown rice flour, add 25kg tap water, 100g α-amylase, stir; In a screw extruder, the barrel temperature is 105° C., and the screw speed is 35 rpm for extrusion. The extruded paste is kept in a boiling water bath at 95°C for 25 minutes; the paste is naturally cooled to a temperature of 62°C, 0.1kg of glucoamylase is added, and kept for saccharification for 4 hours; the mash is naturally cooled to room temperature, and put in 0.1kg of the activated yeast was left to ferment, and when the temperature reached 32°C, it was raked and cooled so that the final temperature was 20°C, fermented for 4 days, and then left to ferment at about 16°C for 20 days; the obtained brown rice wine body directly into storage tanks;

[0031] (2) Preparation of glutinous rice fermentation liquid: select common glutinous rice,...

Embodiment 2

[0042] (1) Select round glutinous rice grains, remove the shells to obtain brown rice, sieve brown rice flour after grinding the brown rice, weigh 200kg of brown rice flour, add 86kg of tap water, 200g of high temperature resistant α-amylase, and stir evenly; In the press, the temperature of the barrel is 115° C., and the screw speed is 50 rpm for extrusion. The extruded paste is kept in a boiling water bath at 95°C for 30 minutes; the paste is cooled to a temperature of 55°C, 0.2 kg of glucoamylase is added, and kept for saccharification for 5 hours; the mash is naturally cooled to room temperature, and placed in 0.24kg of activated yeast was left to ferment, and when the temperature reached 32°C, it was raked and cooled to make the final temperature at 15°C, fermented for 4 days, and then left to ferment at 13°C for 20 days; the obtained brown rice wine body was directly into storage tanks;

[0043] (2) Preparation of glutinous rice fermented liquid: select common glutinous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com