Manufacturing method for producing high-temperature alloy GH4169 fine-grained bar through combined high-speed and radial forging

A GH4169, combined production technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of coarse structure, legacy, and low final forging temperature of finished products, and achieve the improvement of microstructure uniformity, The effect of stable batch production and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, embodiment 2 jointly carry out technique:

[0026] ⑴ Blank opening process of fast forging machine (see Table 1):

[0027] Use the fast forging machine to repeatedly upsetting and drawing the alloy ingot, and the temperature is lowered one by one to open the billet. The cooling gradient is 1110°C±10°C→1100°C±10°C, and the upsetting deformation per fire is 30%; 1080°C±20°C→ 1040°C±20°C, elongated; after fast forging, the billet is directly transferred to the radial forging machine process.

[0028] Example 1

[0029] Alloy ingot ingot shape: Φ508mm, forging specification: Φ165mm, the black skin on the surface is removed by lathe to the finished material specification: Φ150mm;

[0030] ⑵ Diameter forging machine forging process

[0031] After rapid forging, transfer to the radial forging machine process. Before the radial forging, the refiring temperature is 1020°C, and the temperature is kept for 90 minutes.

[0032] ⑶ Organization inspection

[0033] ...

Embodiment 2

[0040] Alloy ingot shape: Φ508mm, forging specification: Φ295mm, finished material specification: Φ280mm;

[0041] ⑵ Diameter forging machine forging process

[0042] Alloy ingot shape: Φ508mm, forging specification: Φ295mm, after lathe removal of black skin on the surface, the finished material specification: Φ280mm;

[0043] ⑵ Diameter forging machine forging process

[0044] After rapid forging, transfer to the radial forging machine process. Before the radial forging, the refiring temperature is 1020 ℃, and the temperature is kept for 120 minutes.

[0045] ⑶ Organization inspection

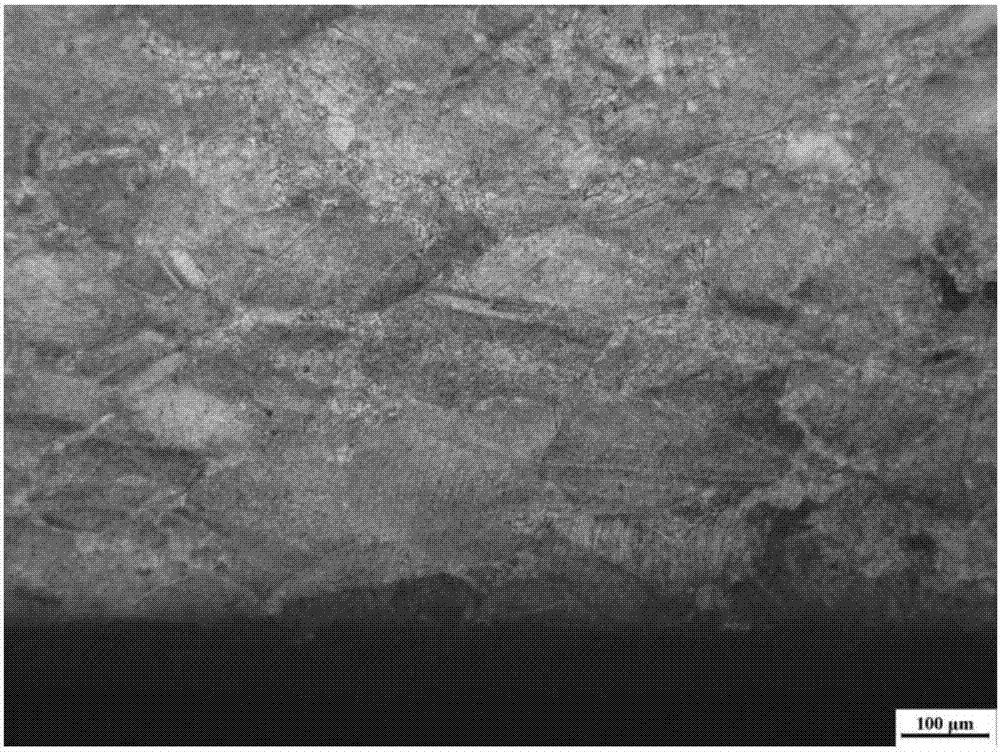

[0046] Lateral hypotissue such as Figure 9 shown;

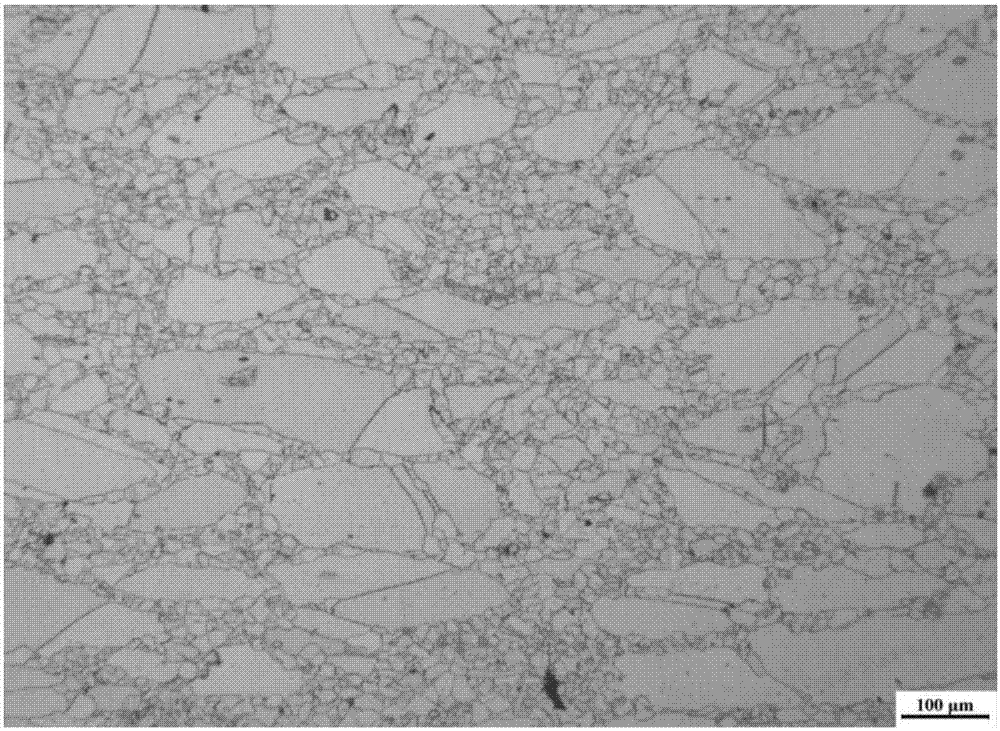

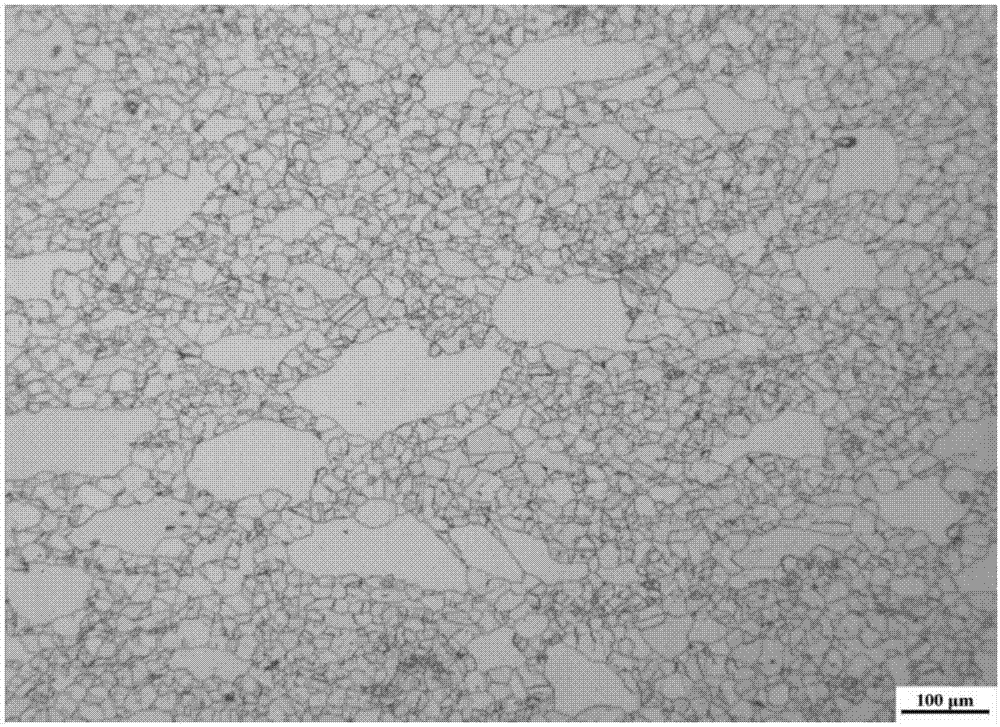

[0047] Longitudinal hypotissue such as Figure 10 shown;

[0048] The microstructure at the outer edge of the bar is as follows Figure 11 shown;

[0049] The microstructure of rod R / 2 position is as follows Figure 12 shown;

[0050] The microstructure at the center of the bar is as Figure 13 shown;

[0051] The grain size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com