Ethyl alcohol dyeing accompanying technology

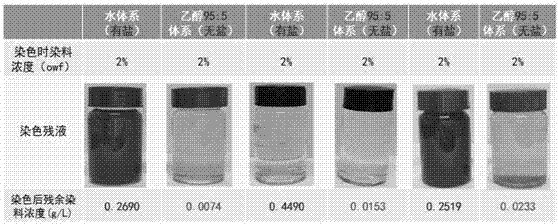

An ethanol and process technology, applied in the field of ethanol accompanying dyeing process, can solve the problems of high environmental pressure, long dyeing time, ecological environment damage, etc., and achieve the effects of reducing the pressure of desalination, shortening the dyeing time, and improving the color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Alkali replacement with bobbin yarn: Add water to the chemical material pool, the amount of water is subject to the amount of water that can submerge the dyed object, water at a temperature of 45°C, add soda ash at an amount of 35g / L and stir for 5 minutes, then add cotton yarn at a rate of 1 per minute ℃ speed to 70 ℃, keep warm for 30 minutes and take it out.

[0038] (2) Liquid-carrying rate control: the liquid-carrying rate processing equipment is used for the alkali-substituting package yarn to make the liquid-carrying rate reach 100%.

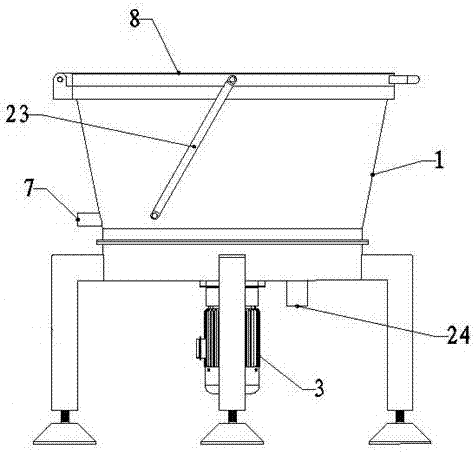

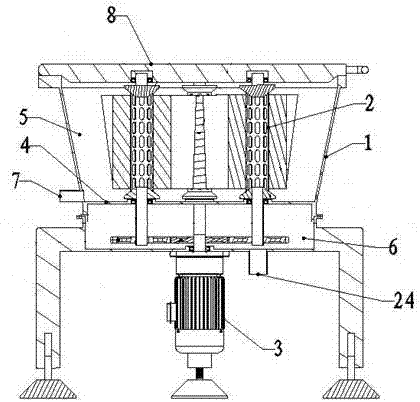

[0039] The liquid-carrying rate processing equipment described in the description attached Figure 2-4 As shown, a barrel body 1, a reel shaft 13, a reel 2 and a drive motor 3 are included.

[0040] The barrel body 1 is divided into an upper dehydration chamber 5 and a lower negative pressure chamber 6 by a horizontal partition 4 . The barrel body 1 is provided with a drain port 7 communicating with t...

Embodiment 2

[0054] cloth dyeing

[0055] (1) Alkali replacement: In the chemical material pool, use a certain amount of water, the amount of water is subject to submerging the dyed object, the water temperature is 50°C, add soda ash in an amount of 30g / L and stir for 5 minutes, then add cotton yarn. Raise the temperature to 70°C at a rate of 1°C per minute, keep it warm for 30 minutes, and take it out with special equipment.

[0056] (2) Liquid-carrying rate control: drying equipment is used to dry at a speed of 15 meters per minute under the condition of 80° C., so that the liquid-carrying rate reaches 80%.

[0057] (3) Dye liquor preparation: dissolve 3% reactive dye by weight of the dyed object into warm water with 5% weight of the dyed object, control the water temperature at 35°C, and fully stir for 20 minutes to form an aqueous dye solution. Pour the dye aqueous solution into an ethanol solution with 95% real weight of the dyed object and stir for 10 minutes to form an ethanol-wate...

Embodiment 3

[0064] cloth dyeing

[0065] (1) Alkali replacement: In the chemical material pool, use a certain amount of water, the amount of water is subject to submerging the dyed object, the water temperature is 50°C, add soda ash in an amount of 30g / L and stir for 5 minutes, then add cotton yarn. Raise the temperature to 70°C at a rate of 1°C per minute, keep it warm for 30 minutes, and take it out with special equipment.

[0066] (2) Liquid-carrying rate control: use liquid-carrying rate processing equipment to carry out liquid-carrying rate treatment, so that the liquid-carrying rate reaches 80%.

[0067] The liquid-carrying rate processing equipment described in the description attached Figure 2-4 As shown, a barrel body 1, a reel shaft 13, a reel 2 and a drive motor 3 are included.

[0068] The barrel body 1 is divided into an upper dehydration chamber 5 and a lower negative pressure chamber 6 by a horizontal partition 4 . The barrel body 1 is provided with a drain port 7 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com