A multifunctional amorphous iron nanometer material, a preparing method thereof and applications of the material

A nanomaterial, iron nanotechnology, applied in the field of nanomaterials and biomedical materials, can solve problems such as harm and neurological dysfunction, and achieve the effects of avoiding side effects, improving specificity, and efficient cancer cell killing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

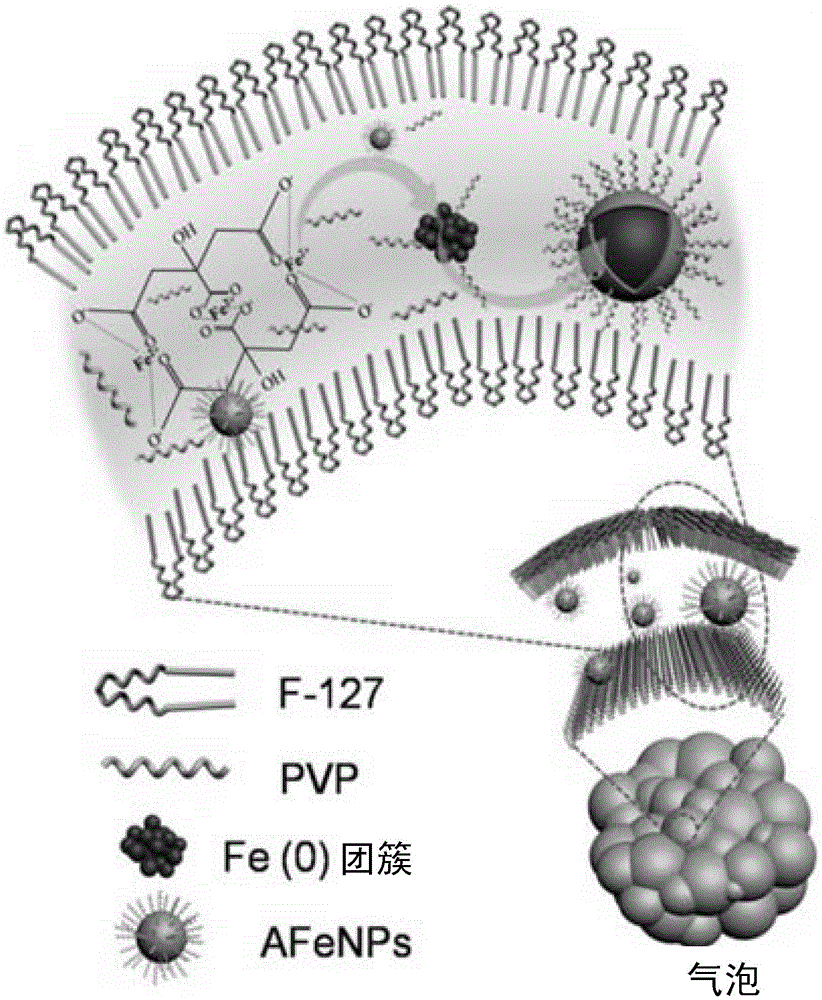

[0072] Ferric sulfate was selected as the iron source, the foaming agent used was Pluronic F127, and the coated organic matter was polyvinylpyrrolidone, wherein the molar ratio of Pluronic F127 to polyvinylpyrrolidone was 10:1, and the precursor solution was obtained by fully stirring , wherein the molar concentration of ferric sulfate solution is 0.02mol / ml, and the molar ratio of foaming agent to ferric sulfate is 1:1. The reducing agent used is sodium hypophosphite, and the molar ratio of reducing agent to iron sulfate is 5:1. The described boiling preparation method synthesizes amorphous iron nanoparticles, and its process includes the following operations:

[0073] a) dissolving ferric sulfate and foaming agent weighed in proportion in water, fully stirring at room temperature, making it evenly mixed to form a precursor solution;

[0074] b) Under the protection of argon, heat to 90°C, keep stirring for 3 hours, and remove dissolved oxygen in the water;

[0075] c) Pass...

Embodiment 1

[0085] Weigh 0.6mol of ferric sulfate, 0.55mol of Pluronic F127 and 0.055mol of polyvinylpyrrolidone, put them in a 100ml three-neck flask, and dissolve them with 30ml of deionized water; under the protection of argon, raise the temperature of the system to 90°C for 3h, fully Remove dissolved oxygen in water; put the argon gas tube into the precursor solution, and bubble for 1 hour; after the bubble system is stable, weigh 3 mol of sodium hypophosphite and dissolve it in 10ml of deionized water, and slowly add it into the reaction system at a rate of 10ml / hour through a syringe pump , and kept warm for 2h under an argon atmosphere; after the reaction was completed, the system temperature dropped to room temperature, and several times of centrifugation and cleaning were performed with deoxygenated water to prepare amorphous iron nanoglasses with polyvinylpyrrolidone surface-modified, which were dispersed in deoxygenated In water, sealed and stored for later use.

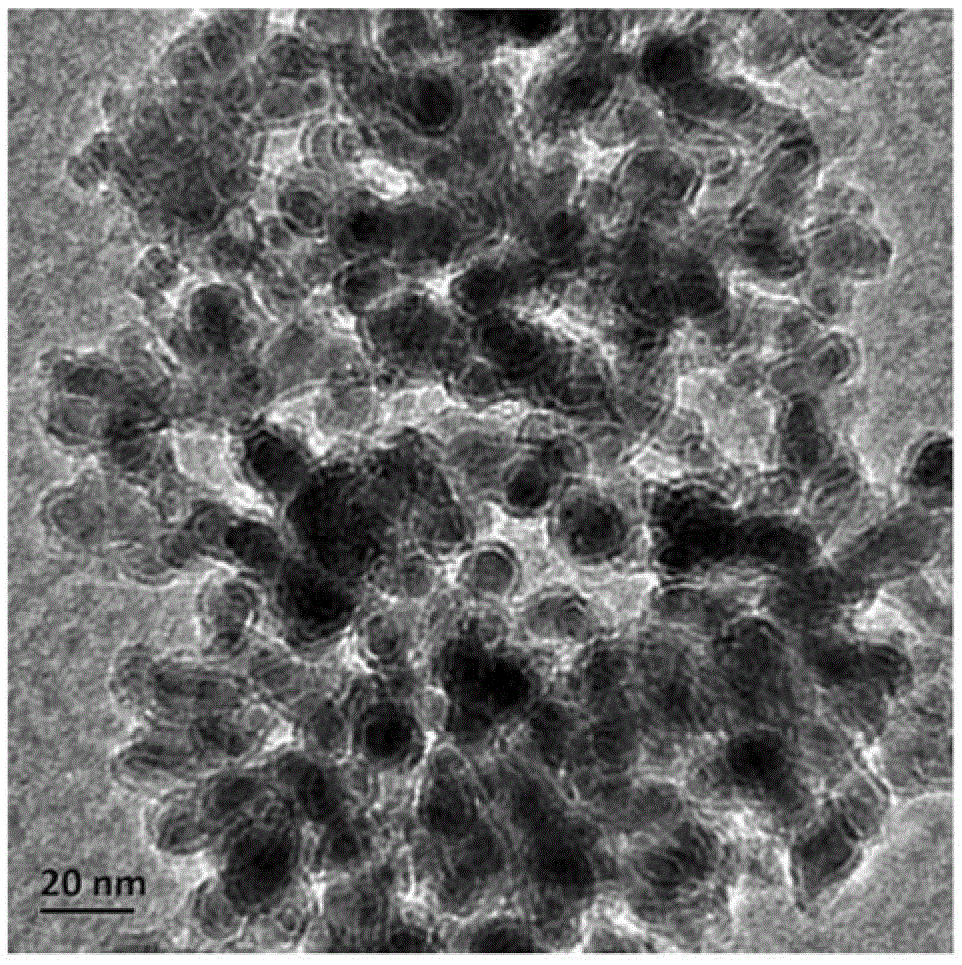

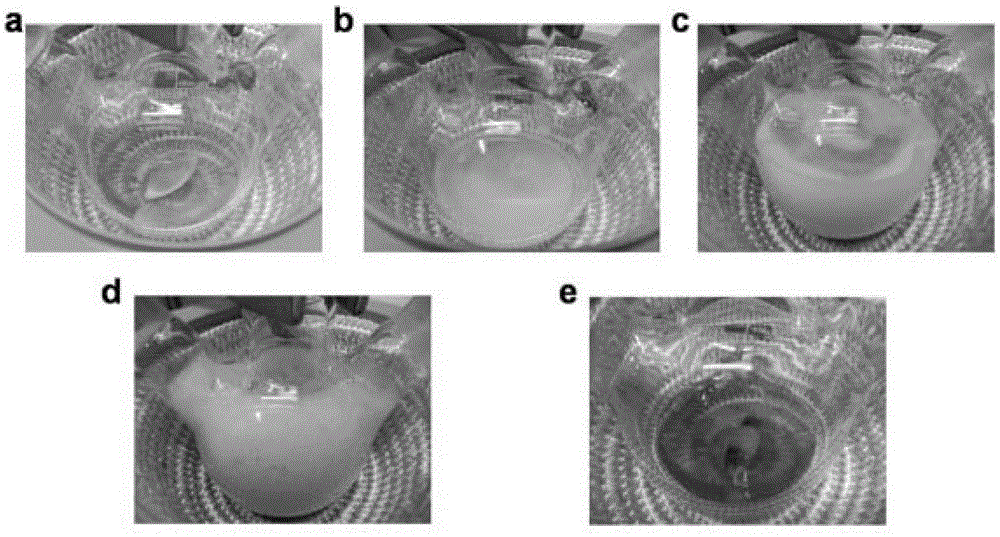

[0086] figur...

Embodiment 2

[0165] Weigh 0.5mol of ferric chloride, 1mol of Pluronic F127 and 0.05mol of polyvinylpyrrolidone, put them in a 100ml three-necked flask, and dissolve them with 30ml of deionized water; under the protection of argon, heat the system to 90°C for 3h, fully Remove dissolved oxygen in water; put the argon gas tube into the precursor solution, and bubble for 1 hour; after the bubble system is stable, weigh 3 mol of sodium borohydride and dissolve it in 10 ml of deionized water, and slowly add it into the reaction system at a rate of 10 ml / hour through a syringe pump , and kept warm for 2h under an argon atmosphere; after the reaction was completed, when the temperature of the system dropped to room temperature, several times of centrifugation and cleaning were performed with deoxygenated water to prepare amorphous iron nanoparticles with polyvinylpyrrolidone surface-modified, which were dispersed in deoxygenated In water, sealed and stored for later use.

[0166] Figure 26 The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com