CdS/Ag/g-C3N4 heterojunction photocatalyst and preparation method thereof

A composite light and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low crystallinity, high exciton binding energy, photogenerated carrier mobility minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

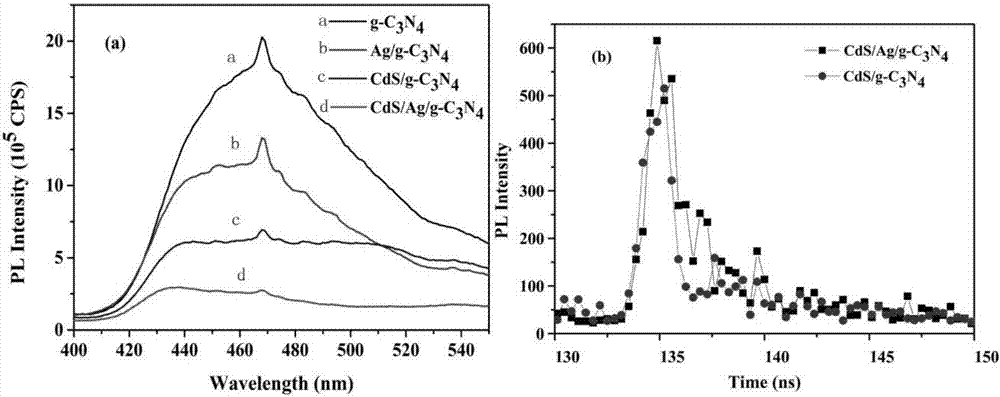

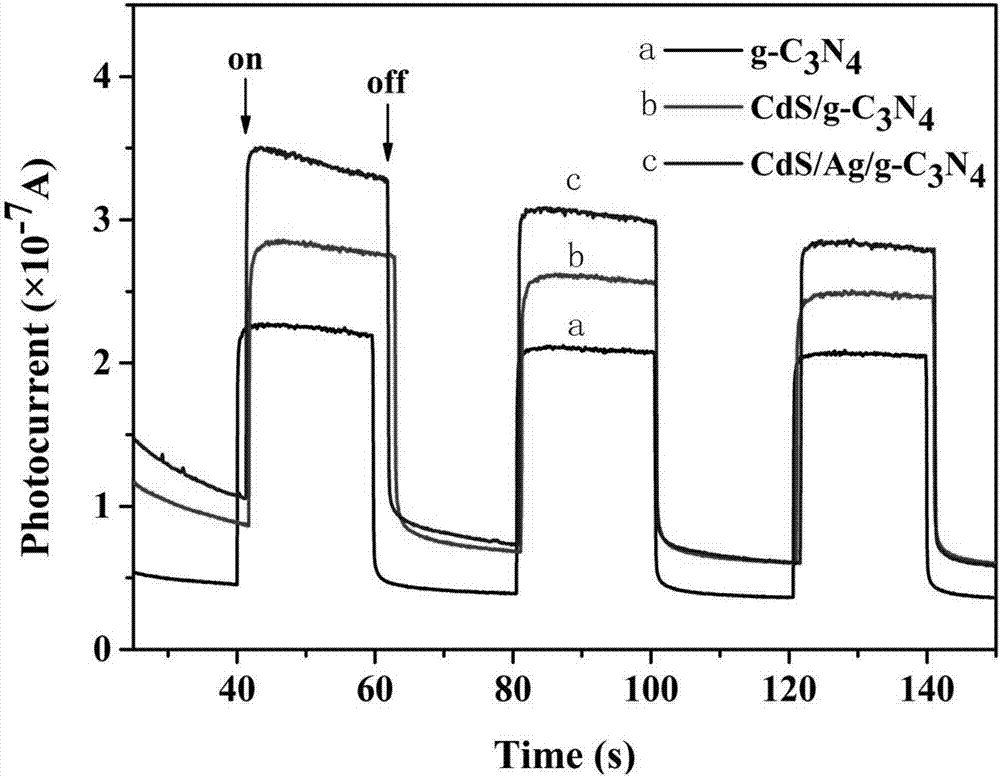

AI Technical Summary

Problems solved by technology

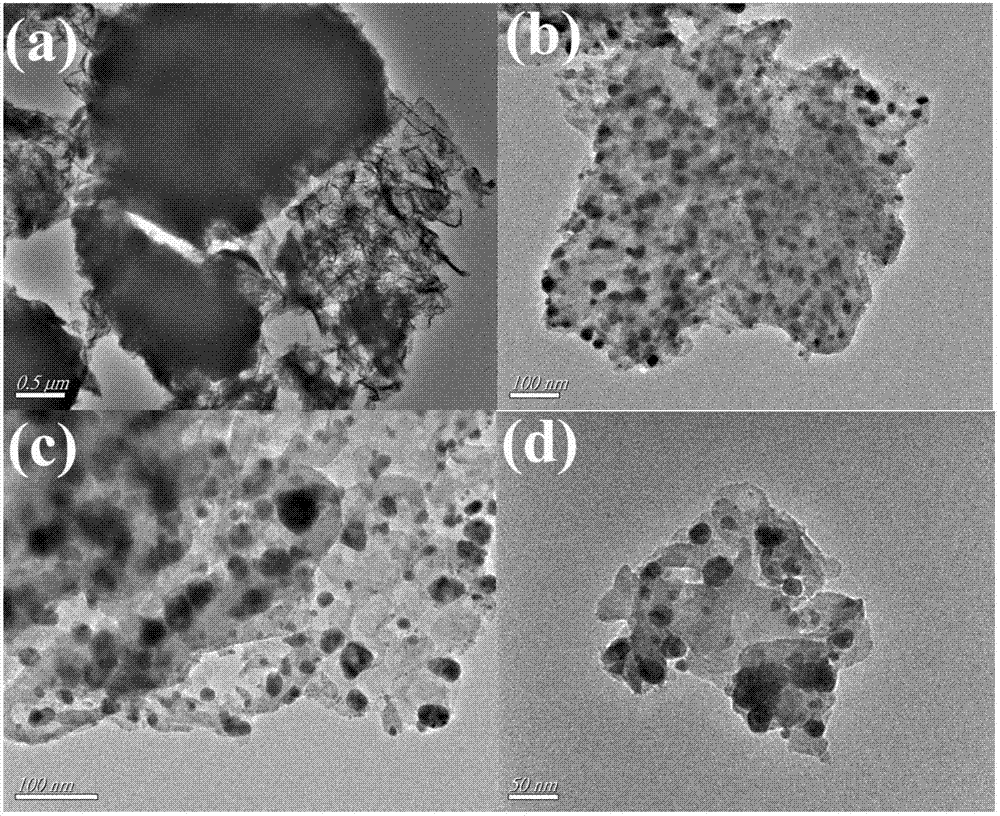

Method used

Image

Examples

Embodiment 1

[0033] (1) g-C 3 N 4 Preparation of nanosheets:

[0034] 5g of melamine was calcined, moved to a 550°C muffle furnace for calcination for 4 hours, and the heating rate was 2.5°C / min. After the calcination is finished, take out and grind; then the powder is calcined in the same procedure to obtain g-C 3 N 4 Nanosheets. Then add 1 g of g-C 3 N 4 The nanosheets are placed in a 90cm 3 Mechanically stir in a beaker of deionized water and 0.40g NaOH for 30min; then, transfer the solution to a 110°C reactor for 18h constant temperature thermal reaction; Dried to give g-C 3 N 4 Nanosheets.

[0035] (2) Ag / g-C 3 N 4 Preparation of:

[0036] 0.20g of g-C 3 N 4 nanosheets and 0.05g AgNO 3 Dissolve in 60ml deionized water and stir; then put the solution under UV light for 3h to reduce AgNO 3 , after the reaction is finished, wait until it drops to room temperature, wash the solid product with deionized water and ethanol, and dry to obtain Ag / g-C 3 N 4 ,spare;

[0037] ...

Embodiment 2

[0041] By the steps in Example 1, the difference is (2) the g-C of 0.20g 3 N 4 nanosheets and 0.01g AgNO 3 Dissolve in 60ml deionized water and stir; then put the solution under UV light for 3h to reduce AgNO 3 , after the reaction is finished, wait until it drops to room temperature, wash the solid product with deionized water and ethanol, and dry to obtain Ag / g-C 3 N 4 .

[0042] The sample in (2) was taken to carry out the photocatalytic degradation test in the photochemical reaction apparatus, and it was measured that the degradation rate of tetracycline by the photocatalyst reached 30.56% within 90 minutes.

Embodiment 3

[0044] By the steps in Example 1, the difference is (2) the g-C of 0.20g 3 N 4 nanosheets and 0.03g AgNO 3 Dissolve in 60ml deionized water and stir; then put the solution under UV light for 3h to reduce AgNO 3 , after the reaction is finished, wait until it drops to room temperature, wash the solid product with deionized water and ethanol, and dry to obtain Ag / g-C 3 N 4 .

[0045] The sample in (2) was taken to carry out the photocatalytic degradation test in the photochemical reaction apparatus, and it was measured that the degradation rate of tetracycline by the photocatalyst reached 50.41% within 90 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com