Solvent-free epoxy prime coat for coating welded joints of pipelines and preparation method thereof

An epoxy primer, solvent-free technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of not meeting the requirements of buried steel pipeline joints, poor resistance to cathodic disbondment, and reduced bonding strength , to achieve the effect of ensuring long-term anti-corrosion effect and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

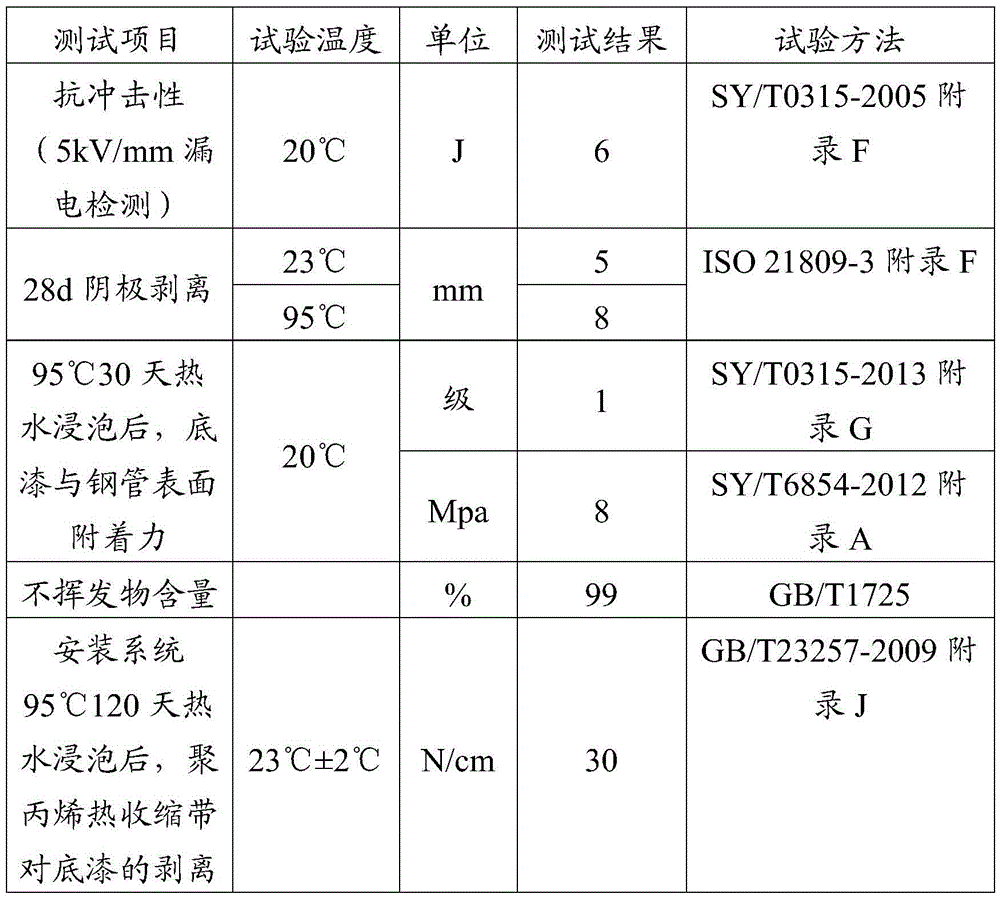

Embodiment 1

[0092] This embodiment provides a kind of solvent-free epoxy primer for pipeline joint, and this solvent-free epoxy primer comprises the following components by mass percentage:

[0093] A component:

[0094] JEh-023 type high temperature resistant epoxy resin, 42 parts;

[0095] ERISYS RDGE type resorcinol epoxy resin, 6 parts;

[0096] F40 type defoamer, 0.3 part;

[0097] Feldspar powder, 51.4 parts;

[0098] Carbon black, 0.3 part;

[0099] B component:

[0100] m-xylylenediamine, 74 parts;

[0101] Isophorone diamine, 26 parts;

[0102] ERISYS RDGE type resorcinol epoxy resin, 4 parts;

[0103] The weight ratio of A component and B component is 100:12.

[0104] The preparation method of the solvent-free epoxy primer of the present embodiment is as follows:

[0105] Step 1, 42 parts by weight of JEh-023 type high temperature resistant epoxy resin, 6 parts by weight of ERISYSRDGE type resorcinol epoxy resin, 0.3 parts by weight of F40 type defoamer, 51.4 parts by w...

Embodiment 2

[0113] This embodiment provides a kind of solvent-free epoxy primer for pipeline joint, and this solvent-free epoxy primer comprises the following components by mass percentage:

[0114] A component:

[0115] JEh-023 type high temperature resistant epoxy resin, 50 parts;

[0116] ERISYS RDGE type resorcinol epoxy resin, 6 parts;

[0117] F40 type defoamer, 0.2 part;

[0118] Feldspar powder, 44.7 parts;

[0119] Carbon black, 0.1 parts;

[0120] B component:

[0121] m-xylylenediamine, 70 parts;

[0122] Isophorone diamine, 30 parts;

[0123] ERISYS RDGE type resorcinol epoxy resin, 5 parts;

[0124] The weight ratio of A component and B component is 100:14.

[0125]The preparation method of the solvent-free epoxy primer of the present embodiment is as follows:

[0126] Step 1, 50 parts by weight of JEh-023 type high temperature resistant epoxy resin, 6 parts by weight of ERISYSRDGE type resorcinol epoxy resin, 0.2 parts by weight of F40 type defoamer, 44.7 parts by w...

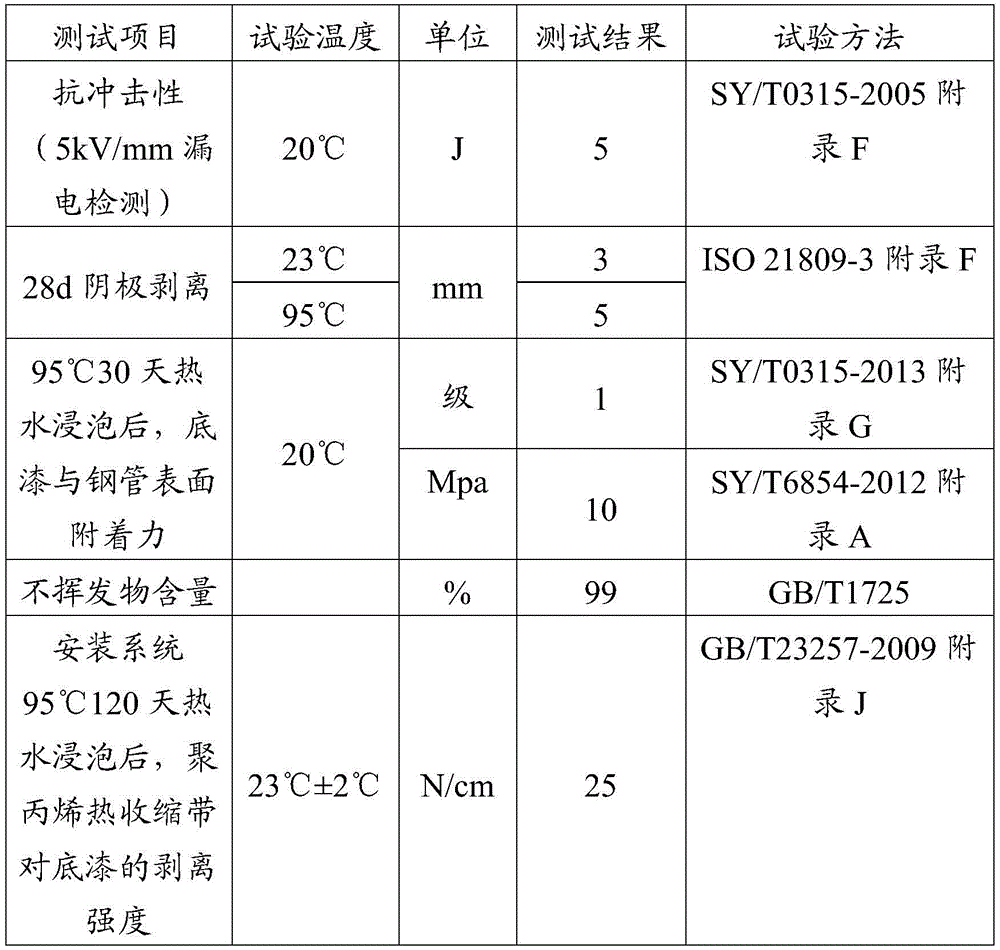

Embodiment 3

[0133] This embodiment provides a kind of solvent-free epoxy primer for pipeline joint, and this solvent-free epoxy primer comprises the following components by mass percentage:

[0134] A component:

[0135] JEh-023 type high temperature resistant epoxy resin, 46 parts;

[0136] ERISYS RDGE type resorcinol epoxy resin, 6 parts;

[0137] F40 type defoamer, 0.3 parts;

[0138] Feldspar powder, 47.5 parts;

[0139] Carbon black, 0.2 parts;

[0140] B component:

[0141] m-xylylenediamine, 75 parts;

[0142] Isophoronediamine, 25 parts;

[0143] ERISYS RDGE type resorcinol epoxy resin, 5 parts;

[0144] The weight ratio of A component and B component is 100:14.

[0145] The preparation method of the solvent-free epoxy primer of the present embodiment is as follows:

[0146] Step 1, 46 parts by weight of JEh-023 type high temperature resistant epoxy resin, 6 parts by weight of ERISYSRDGE type resorcinol epoxy resin, 0.3 part by weight of F40 type defoamer, 47.5 parts by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com