Method for producing raw material for needle-like coke

A technology of needle coke raw material and production method, which is applied to the refining and cracking process treatment of multi-stage series connection, petroleum industry, processing of hydrocarbon oil, etc. rate and other issues, to achieve the effects of low cost, high yield, and large operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

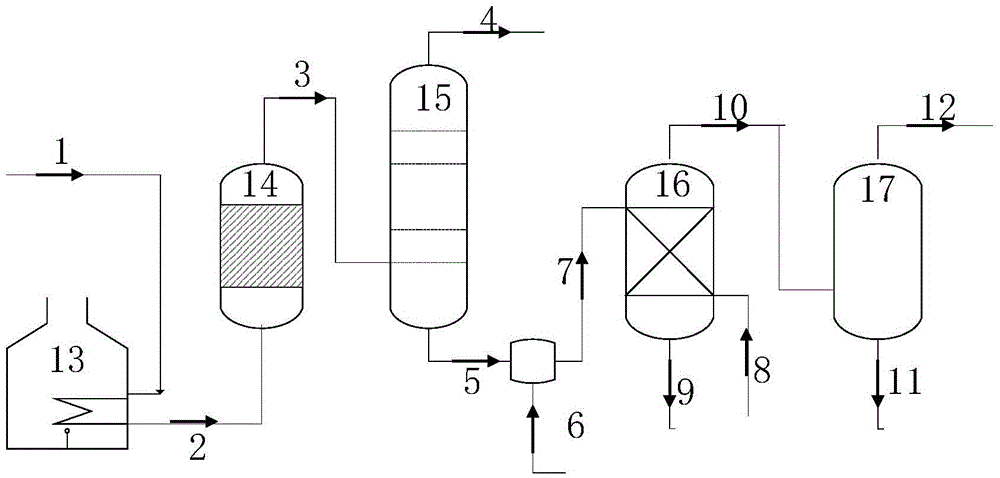

Method used

Image

Examples

Embodiment 1

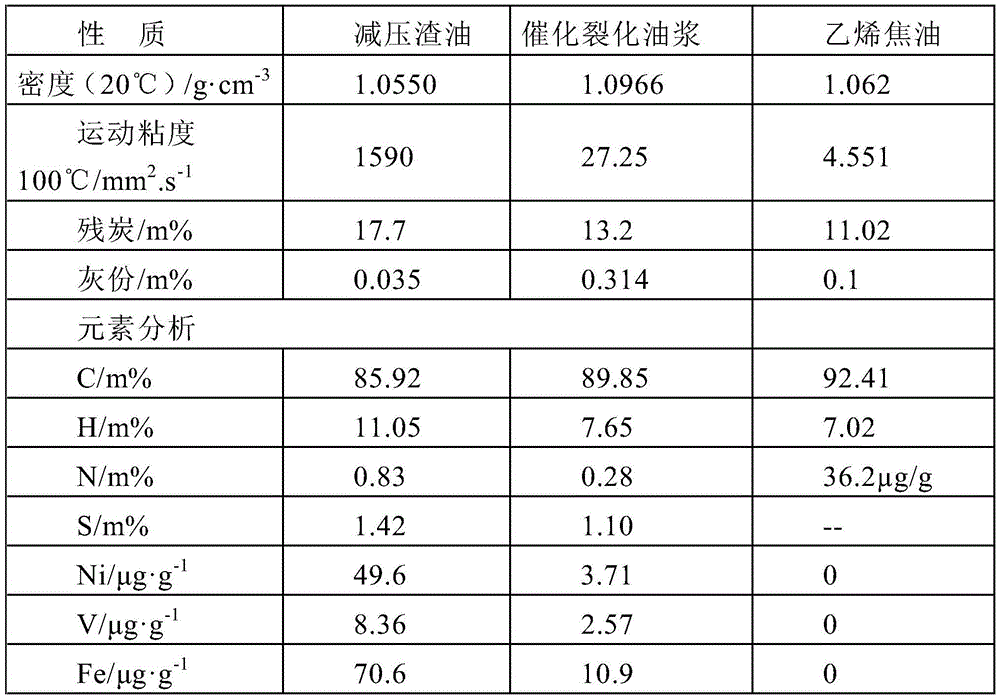

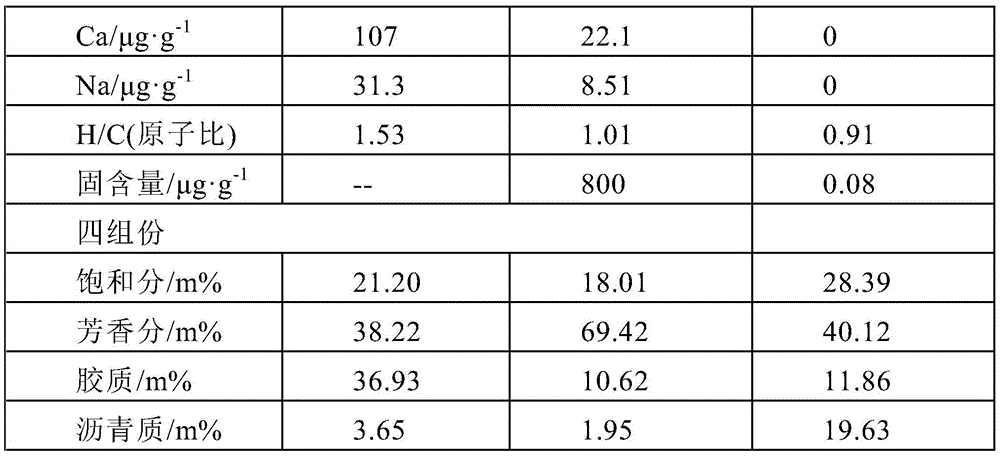

[0057] In Example 1, the raw material oil is a mixture of vacuum residue and catalytic cracking oil slurry with a mass ratio of 1:1, and the added catalyst is LBO-16 catalytic cracking catalyst, and the addition amount is 0.5% of the raw material oil quality; Example 2 The raw material oil is catalytic cracking oil slurry; the raw material oil in Example 3 is ethylene tar, and the added catalyst is CHN-1 residual oil catalytic cracking catalyst, and the added amount is 3% of the raw material oil quality. The properties of the raw oil are shown in Table 1, the main process conditions of visbreaking are shown in Table 2; the main process conditions of solvent deasphalting are shown in Table 3; the properties of the needle coke raw materials obtained in the examples are shown in Table 4.

[0058] The raw material oil properties used in the embodiment of table 1

[0059]

[0060]

[0061] Table 2 Main process conditions of visbreaking reaction

[0062] project E...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap