Equipment system suitable for carbon dioxide cycle power generation using biomass as energy in rural areas

A technology of carbon dioxide and cycle power generation, which is applied in mechanical equipment, transportation and packaging, steam engine devices, etc., can solve the problems of unsuitable cycle power generation, high energy consumption of compressors, and large system investment, so as to achieve simple mechanism and reduce self-consumption energy, stable operating conditions and the effect of power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

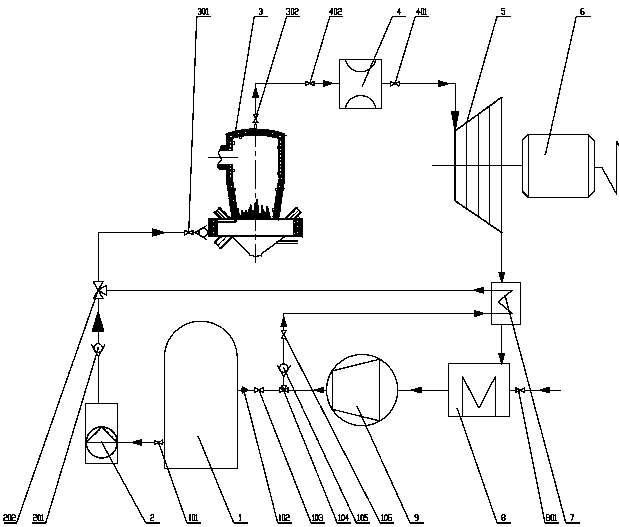

Embodiment 1

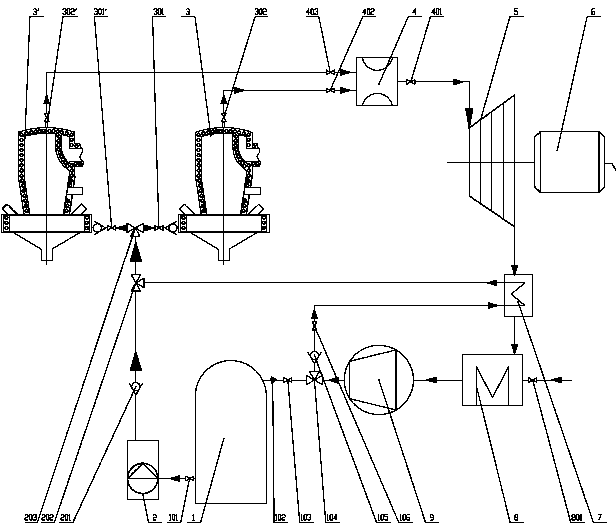

[0041] refer to figure 2 , one adopts 2 sets of boiling furnace CO 2 The equipment system of the energy storage device, mainly including liquid CO 2 Tank 1, CO 2 High-pressure pumping device 2, biomass furnace CO 2 Energy storage device 3, the second biomass furnace CO 2 Energy storage device 3′, steady flow regulator 4, turbine 5, generator 6, regenerator 7, cooler 8 and compressor 9, the liquid CO 2 The outlet of storage tank 1 is connected with CO through the first pipeline valve 101 2 The inlet of the high-pressure pumping device 2 is connected, and the CO 2 The outlet of the high-pressure pumping device 2 communicates with the first three-way valve 202 through the first check valve 201, the first three-way valve 202 communicates with the third three-way valve 203, and the third three-way valve 203 communicates with the third three-way valve 203 through the second pipeline valve 301. Biomass furnace CO 2 The inlet of the energy storage device 3 is connected, and th...

Embodiment 2

[0043] refer to image 3 , one featuring 2 sets of liquid CO 2 Storage tank + 3 sets of high pressure pumps + 3 sets of boiling furnace CO 2 The equipment system of the energy storage device, mainly including liquid CO 2 Storage tank 1, the second liquid CO 2 Storage tank 1ˊ, CO 2 High-pressure pumping device 2, the second CO 2 High-pressure pumping device 2ˊ, the third CO 2 High-pressure pumping device 2", biomass furnace CO 2 Energy storage device 3, the second biomass furnace CO 2 Energy storage device 3ˊ, third biomass furnace CO 2 Energy storage device 3", steady flow regulator 4, turbine 5, generator 6, regenerator 7, cooler 8 and compressor 9, the liquid CO 2 Storage tank 1, the second liquid CO 2The inlet of the storage tank 1' is connected through the second check valve 102, the seventh pipeline valve 103, the second three-way valve 104, the twelfth pipeline valve 103', and the third check valve 102', and the liquid CO 2 The outlet of storage tank 1 is conne...

Embodiment 3

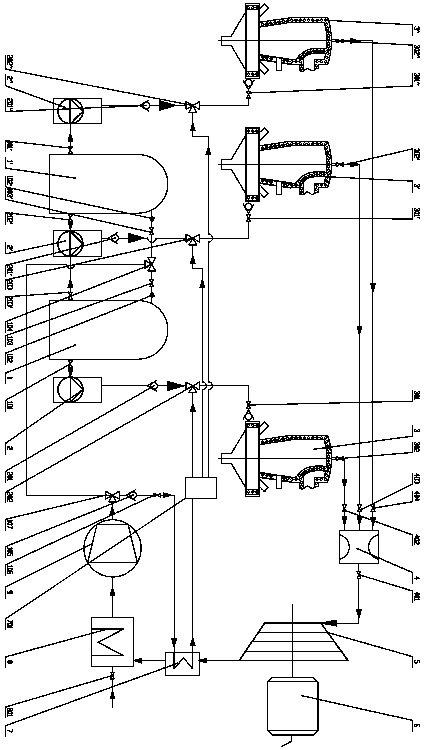

[0046] refer to Figure 4 , one using 2 sets of liquid CO 2 Storage tank + 2 sets of high pressure pumps for 2 sets of boiling furnace CO respectively 2 Energy storage device and 2 sets of grate furnace CO 2 The equipment system of the energy storage device, mainly including liquid CO 2 Storage tank 1, etc. 2 Liquid CO 2 Storage tank 1ˊ, CO 2 High-pressure pumping device 2, etc. two CO 2 High-pressure pumping device 2ˊ, boiling furnace CO 2 Energy storage device 3B, etc. 2 fluidized furnace CO 2 Energy storage device 3Bˊ, grate furnace CO 2 Energy storage device 3A, etc. the second grate furnace CO 2 Energy storage device 3A′, steady flow regulator 4, turbine 5, generator 6, regenerator 7, cooler 8 and compressor 9, the liquid CO 2 Storage tank 1, etc. 2 Liquid CO 2 The inlet of the storage tank 1' is connected through the second check valve 102, the seventh pipeline valve 103, the second three-way valve 104, the twelfth pipeline valve 103', and the third check valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com