A kind of processing method of salted jellyfish desalted alum semi-dry packaged food

A processing method and desalted alum technology, which is applied in the field of processing salted jellyfish desalted alum semi-dry packaging products, can solve the problems of tissue fiber damage, jellyfish protein denaturation, hardness decrease, etc., and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

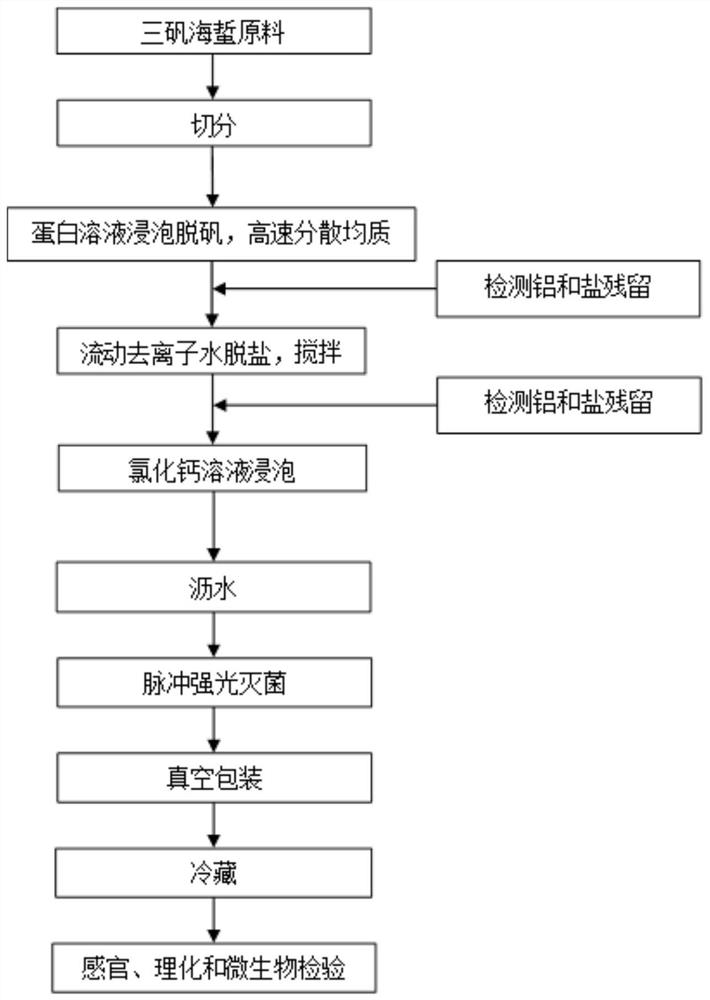

Method used

Image

Examples

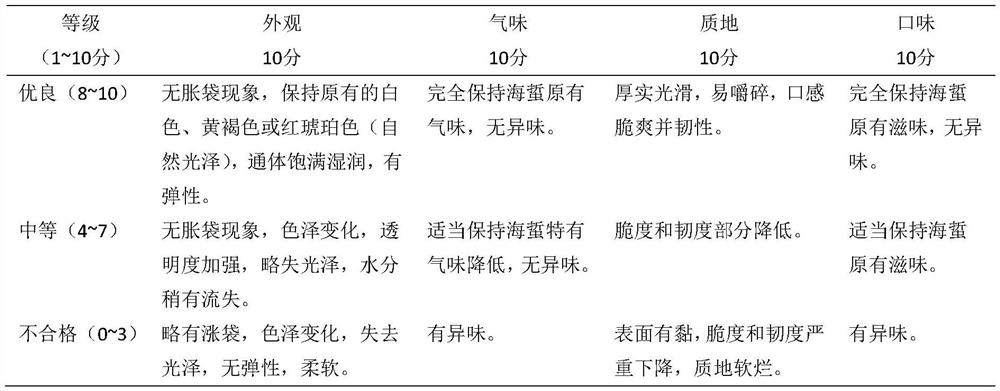

Embodiment 1

[0051] Take 500g of jellyfish head raw materials (moisture content 65.8%, aluminum content 485.2mg / kg, salt content 21.7%) → cut into 0.5cm × 3cm or so in size → add according to the mass ratio of jellyfish and mixed solution of 1:5 5L of a mixed solution of 0.01% casein solution and 0.1% food grade sodium bicarbonate, under the condition of ice bath at 2°C, act on a high-speed dispersing homogenizer for 1min, let it stand for 10min, pour off the liquid (measured aluminum content 72.1mg / kg, salt content 6.4mg / kg) → Pour 2.5L of deionized water into the original mass (500g) with a solid-to-liquid ratio of 1:5, and act on a high-speed dispersing homogenizer for 1min in an ice bath at 2°C. Pour off the liquid (the measured aluminum content is 48.4mg / kg, and the salt content is 3.1mg / kg) → add calcium chloride solution to the desalted jellyfish, and pour 2.5L of 1% food-grade calcium chloride, act in an ice bath at 2°C for 10 minutes → drain for 30 minutes → pulse strong light st...

Embodiment 2

[0054] Take 500g of jellyfish head raw materials (moisture content 65.8%, aluminum content 485.2mg / kg, salt content 21.7%) → cut into about 0.5cm×3cm in size → add according to the mass ratio of jellyfish and mixed solution of 1:10 5L of a mixed solution of 0.01% casein solution and 0.1% food grade sodium bicarbonate, under the condition of ice bath at 2°C, act on a high-speed dispersing homogenizer for 1min, let it stand for 10min, pour off the liquid (measured aluminum content 72.1mg / kg, salt content 6.4mg / kg) → Pour 5L of deionized water into the original mass (500g) with a solid-to-liquid ratio of 1:10. Under the condition of 2℃ ice bath, act on the high-speed dispersing homogenizer for 1min, pour Liquid (measured aluminum content 48.4mg / kg, salt content 3.1mg / kg) → add calcium chloride solution to the desalted jellyfish, pour 2.5L 0.1% of the original mass (500g) with a solid-liquid ratio of 1:5 Food-grade calcium chloride, act in an ice bath at 2°C for 30 minutes → drai...

Embodiment 3

[0057] Take 500g of jellyfish head raw material (moisture content 65.8%, aluminum content 485.2mg / kg, salt content 21.7%) → cut into pieces → add 10L 0.03% casein solution according to the mass ratio of jellyfish and mixed solution of 1:20 , 0.3% food-grade sodium bicarbonate, under the condition of 2 ℃ ice bath, high-speed dispersing homogenizer for 3 minutes, let stand for 30 minutes, pour off the liquid (measured aluminum content 43.6mg / kg, salt content 5.5mg / kg) → According to the solid-to-liquid ratio of the original mass (500g) of 1:20, pour 10L of deionized water into it. Under the condition of ice bath at 2°C, the high-speed dispersion homogenizer acts for 1min, and the liquid is poured out (the measured aluminum content is 25.2mg / kg , salt content 2.4mg / kg) → add calcium chloride solution to the desalted jellyfish, pour 5L 0.5% food grade calcium chloride into the original mass (500g) with a solid-to-liquid ratio of 1:10, ice bath for 60min → drain 60min→pulse strong ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com