Nanometer silver wire and preparing method thereof

A nano-silver wire and preparation process technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of cumbersome process, low yield of nano-silver wire, production cost pressure, etc., and achieve uniform size distribution and shape Controllable appearance and size, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

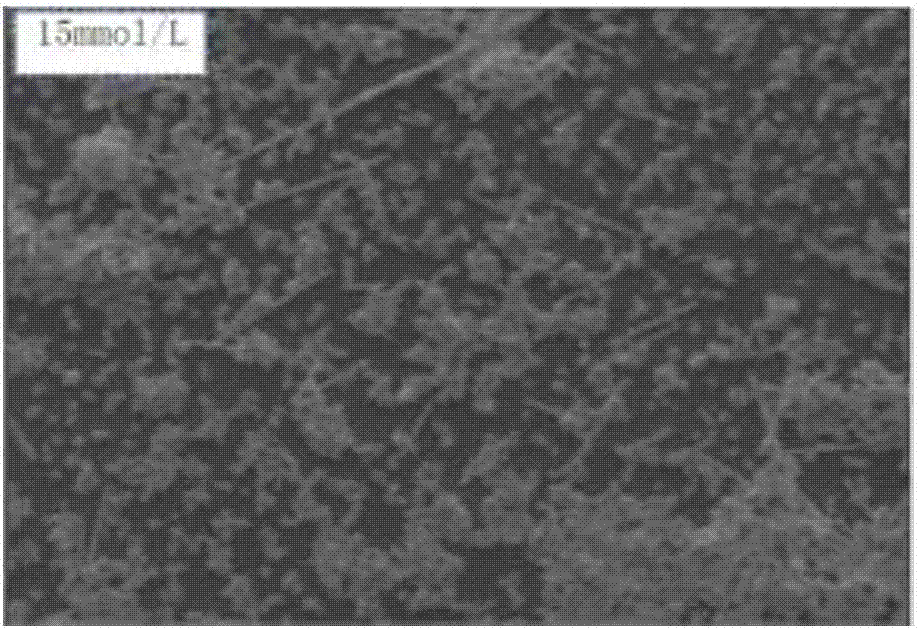

[0035] Embodiment 1Cl-concentration is 15mmol / L

[0036] 5ml CuCl 2 (AR) 15mmol / L, 5ml PVP (AR) 0.15mol / L, 5ml AgNO 3 (AR) 0.1mol / L, weigh the raw materials according to this ratio, and dissolve them in ethylene glycol solvent respectively; then slowly add the prepared three solutions into 10ml of ethylene glycol solvent, and stir evenly, Then put it into a reaction kettle, raise the temperature to 140°C in an electric constant temperature blast drying oven, and keep it warm for 24 hours; naturally cool to room temperature, take it out and centrifugally purify to obtain the nano-silver product. Test spectra such as figure 1 shown.

[0037] Such as figure 1 The nano-silver obtained under the concentration shown is mainly spherical.

Embodiment 2

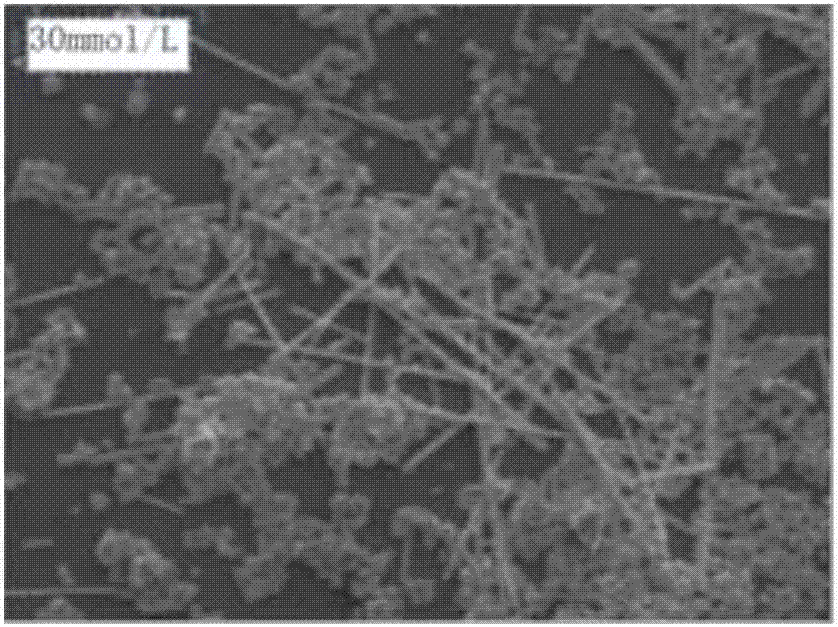

[0038] Embodiment 2Cl-concentration is 30mmol / L

[0039] 6ml NaCl (AR) 30mmol / L, 6ml PVP (AR) 0.15mol / L, 6ml AgNO 3 (AR) 0.1mol / L, weigh the raw materials according to this ratio, and dissolve them in ethylene glycol solvent respectively; then slowly add the prepared three solutions into 15ml of ethylene glycol solvent, and stir evenly, Then put it into the reaction kettle, raise the temperature to 160°C in an electric constant temperature blast drying oven, and keep it warm for 15 hours; naturally cool to room temperature, take it out and centrifugally purify to obtain the nano-silver product. Test spectra such as figure 2 shown.

[0040] Such as figure 2 The nano-silver wires obtained under the concentration shown in the figure are obviously increased and the particles are reduced.

Embodiment 3

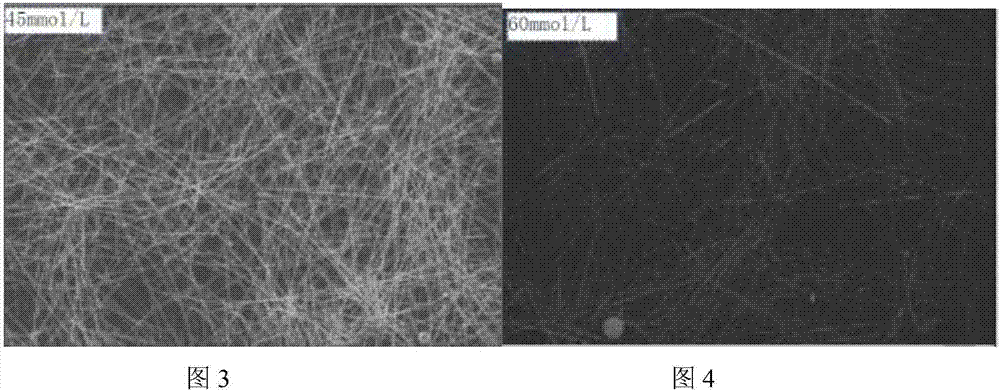

[0041] Embodiment 3Cl-concentration is 45mmol / L

[0042] 6ml NaCl (AR) 45mmol / L, 6ml PVP (AR) 0.15mol / L, 6ml AgNO 3 (AR) 0.1mol / L, weigh the raw materials according to this ratio, and dissolve them in the propylene glycol solvent respectively; In the kettle, the temperature was raised to 140°C in a muffle furnace, and kept for 20 hours; naturally cooled to room temperature, taken out and purified by centrifugation to obtain silver nanowires. The test spectrum is shown in Figure 3. One of the nano-silver wires was selected for measurement, with a diameter of about 42nm, a length of about 46um, and an aspect ratio of 1095.

[0043] As shown in Figure 3, the nano-silver obtained under this concentration is mainly linear. The yield is as high as 90%, and the concentration of Cl- is optimal at this time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com