A kind of method utilizing microchannel reaction device to prepare deuterated aniline compounds

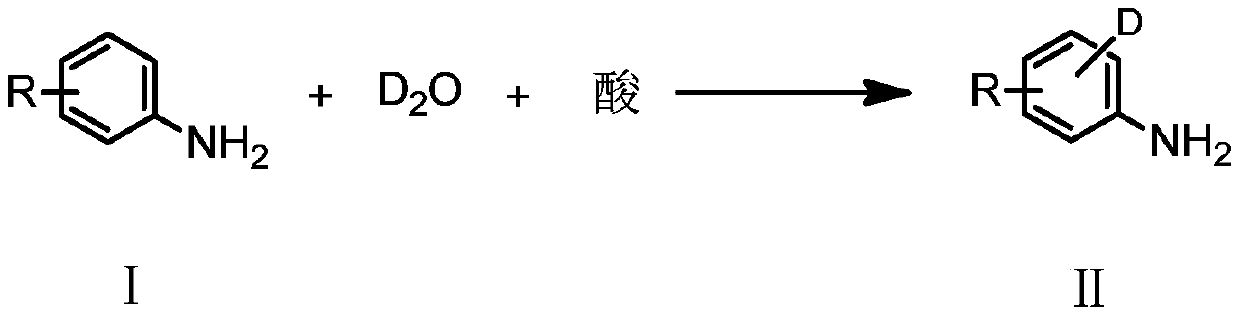

A technology of aniline compounds and microchannel reaction, which is applied in the preparation of amino compounds from amines, the preparation of organic compounds, organic chemical methods, etc., can solve the problems of large amount of heavy water usage, incomplete deuterium, long reaction time, etc., to achieve Reduced usage of heavy water, high deuterium rate, shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

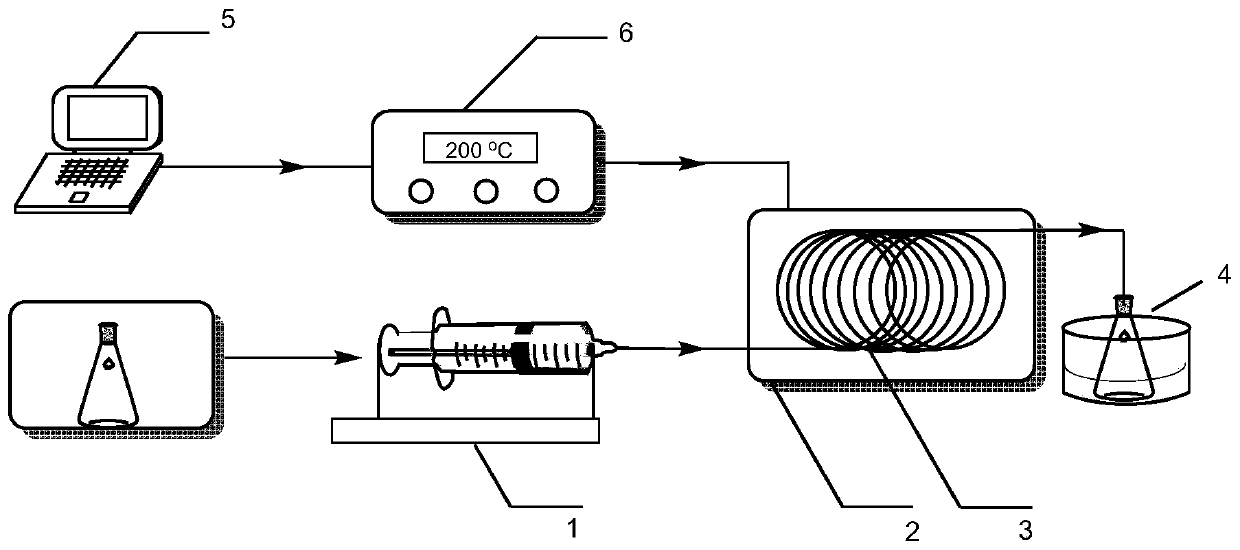

Method used

Image

Examples

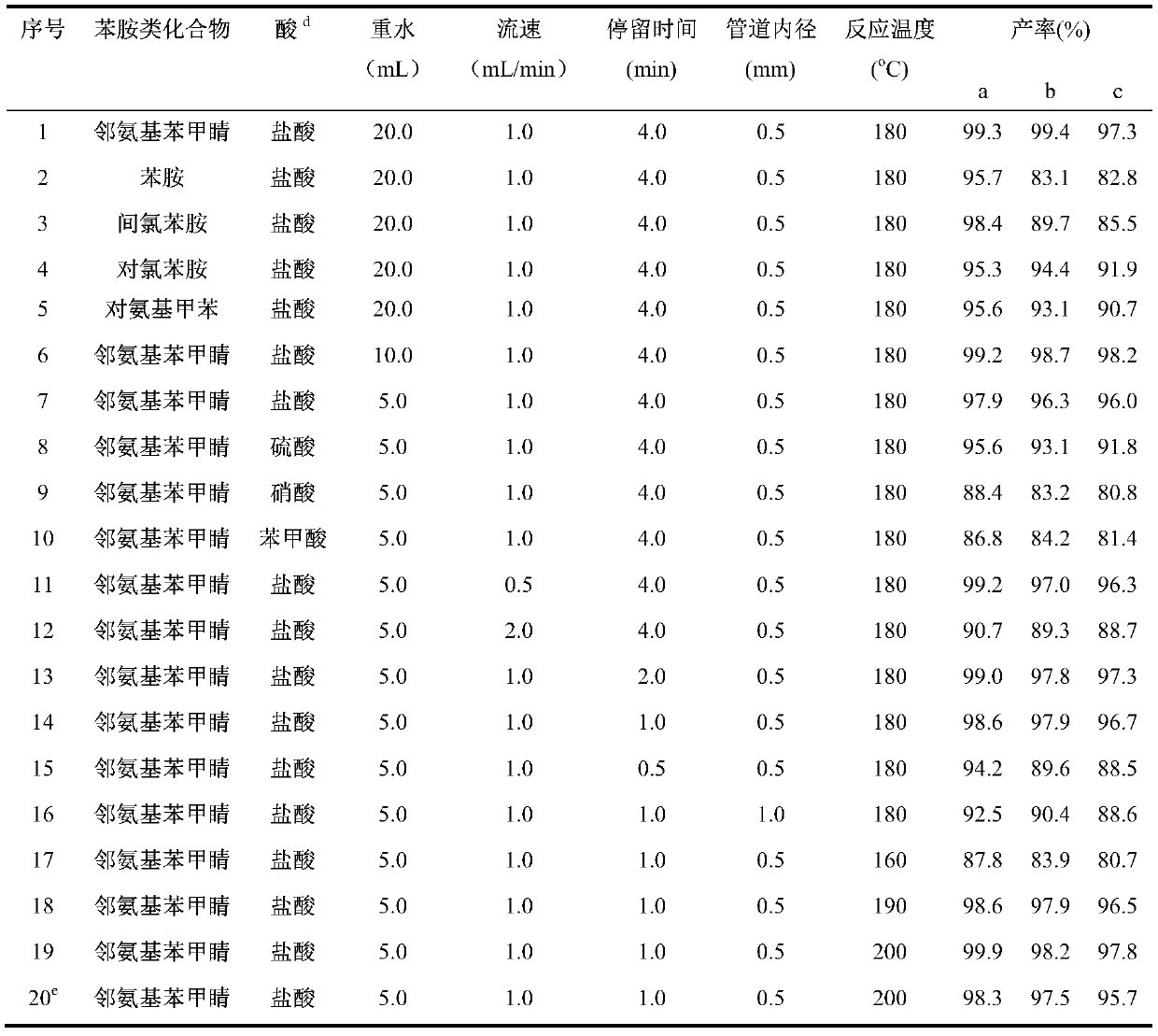

Embodiment 1

[0034] Weigh anthranilonitrile (1.0equiv, 4.0mmol), measure hydrochloric acid heavy aqueous solution (1.0equiv, 0.2M, 20.0mL) and place in a sealed conical flask for ultrasonic mixing for 30min; The solution was pushed into the microchannel reactor at a flow rate of 1.0 mL / min by a syringe pump after exhausting the air in the syringe, and the residence time was 4 min. The above-mentioned microchannel reactor is placed in a microwave field with an inner diameter of 0.5mm. The above reaction temperature is 180° C., and the reaction liquid is collected after the reaction is completed. The conversion rate was 99.3%, the deuteration rate was 99.4%, and the isolated yield was 97.3%.

Embodiment 2

[0036] Weigh aniline (1.0equiv, 4.0mmol), measure hydrochloric acid heavy aqueous solution (1.0equiv, 0.2M, 20.0mL) and place in a conical flask, seal and ultrasonically mix for 30min; The air in the syringe is then pushed into the microchannel reactor at a flow rate of 1.0 mL / min by a syringe pump, and the residence time is 4 min. The above-mentioned microchannel reactor is placed in a microwave field with an inner diameter of 0.5mm. The above reaction temperature is 180° C., and the reaction liquid is collected after the reaction is completed. The conversion rate was 95.7%, the deuteration rate was 83.1%, and the isolated yield was 82.8%.

Embodiment 3

[0038] Weigh m-chloroaniline (1.0equiv, 4.0mmol), measure hydrochloric acid heavy aqueous solution (1.0equiv, 0.2M, 20.0mL) and place in a sealed conical flask for ultrasonic mixing for 30min; use a syringe to extract the mixed solution after ultrasonic mixing, After exhausting the air in the syringe, push it into the microchannel reactor at a flow rate of 1.0 mL / min with a residence time of 4 min through a syringe pump. The above-mentioned microchannel reactor is placed in a microwave field with an inner diameter of 0.5mm. The above reaction temperature is 180° C., and the reaction liquid is collected after the reaction is completed. The conversion rate was 98.4%, the deuteration rate was 89.7%, and the isolated yield was 85.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com