Ramie fiber modified dibutyl benzenedicarboxylate composite and preparation method thereof

A technology of non-butylene phthalate and butylene terephthalate, applied in the field of ramie fiber modified butylene phthalate composite material and its preparation, can solve the problems of high cost and insufficient tensile strength , to achieve the effects of poor elasticity, enhanced mechanical properties, and high degree of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

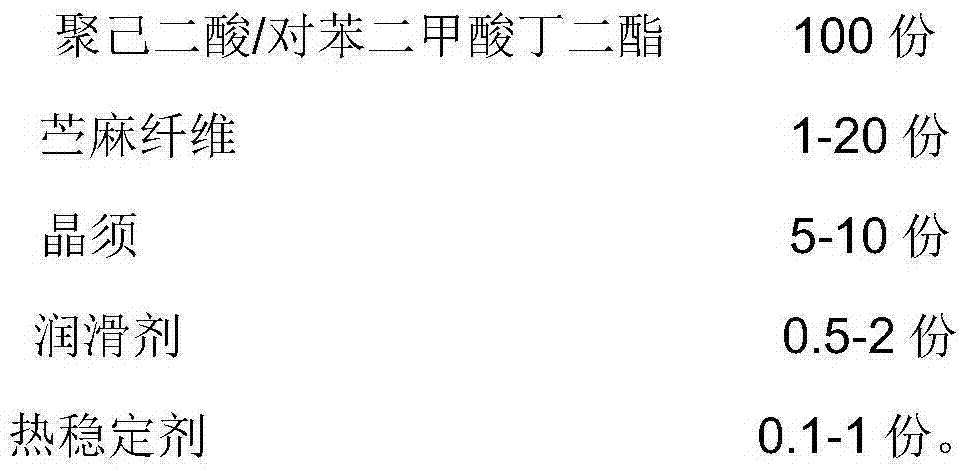

[0025] In the present embodiment, calculated by mass parts, the composition and content are as follows:

[0026]

[0027] Above-mentioned formula reacts according to the following steps:

[0028] (1) First immerse the ramie fibers in lye with a mass concentration of 4% (mixing ratio of solid to liquid weight: 1:20), treat them at 25°C for 2 hours, wash out the alkali with water, remove the alkali in an acid bath, and wash with water until neutral , after drying to obtain ramie

[0029] Fiber spare.

[0030] (2) Mix the whiskers with 50ml of absolute ethanol, and ultrasonically disperse for 10 minutes to obtain a uniformly dispersed suspension; add γ-aminopropyltriethoxysilane coupling agent (KH550) (0.5% by mass fraction of whiskers) Dissolve in 50ml of absolute ethanol; mix the homogeneous suspension with the coupling agent solution and reflux at 80°C for 3 hours; cool to room temperature, centrifuge, and dry in a vacuum oven at 80°C

[0031] (3) above-mentioned whisker...

Embodiment 2

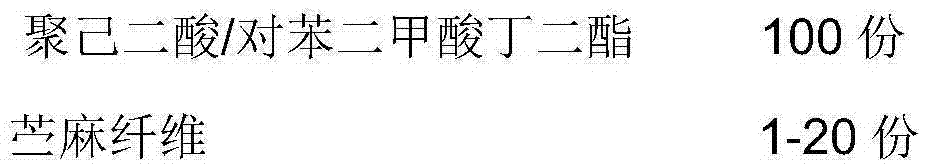

[0036] In the present embodiment, calculated by mass parts, the composition and content are as follows:

[0037]

[0038] Above-mentioned formula reacts according to the following steps:

[0039] (1) First, ramie fibers were immersed in lye with a mass concentration of 3% (solid-liquid weight mixing ratio 1:20), treated at 25°C for 3 hours, washed with water, de-alkalied with acid bath, and washed with water until neutralized. After drying, ramie fibers are obtained for future use.

[0040] (2) Mix the whiskers with 50ml of absolute ethanol, and ultrasonically disperse for 10 minutes to obtain a uniformly dispersed suspension; dissolve the titanate coupling agent NZD-201 (0.5% by mass fraction of the whiskers) in 50ml of absolute ethanol; Mix the homogeneous suspension and the coupling agent solution evenly and reflux at 80°C for 3 hours; cool to room temperature, centrifuge and dry in a vacuum oven at 80°C

[0041] (3) above-mentioned whisker, ramie fiber and polyadipate...

Embodiment 3

[0046] In the present embodiment, calculated by mass parts, the composition and content are as follows:

[0047]

[0048] Above-mentioned formula reacts according to the following steps:

[0049] (1) First immerse the ramie fiber in lye solution with a mass concentration of 2.5% (solid-liquid weight mixing ratio 1:20), treat it at 25°C for 3 hours, wash it with water, remove the alkali with acid bath, and wash with water until neutral , after drying, the ramie fiber is obtained for future use.

[0050] (2) Mix the whiskers with 50ml of absolute ethanol, and ultrasonically disperse for 10 minutes to obtain a uniformly dispersed suspension; add γ-aminopropyltriethoxysilane coupling agent (KH550) (0.5% by mass fraction of whiskers) Dissolve in 50ml of absolute ethanol; mix the homogeneous suspension with the coupling agent solution and reflux at 80°C for 3 hours; cool to room temperature, separate by centrifugation, and dry in a vacuum oven at 80°C

[0051] (3) above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com