Method for preparing nickel cobalt lithium manganate lithium-ion battery positive material from waste lithium batteries

A lithium-ion battery, nickel-cobalt-lithium-manganese-oxide technology, which is applied in the field of waste lithium batteries to prepare nickel-cobalt-lithium-manganate-lithium-ion battery cathode materials, can solve the problems of low product capacity, uneven element distribution, and low energy density, and achieve The effect of saving resources and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

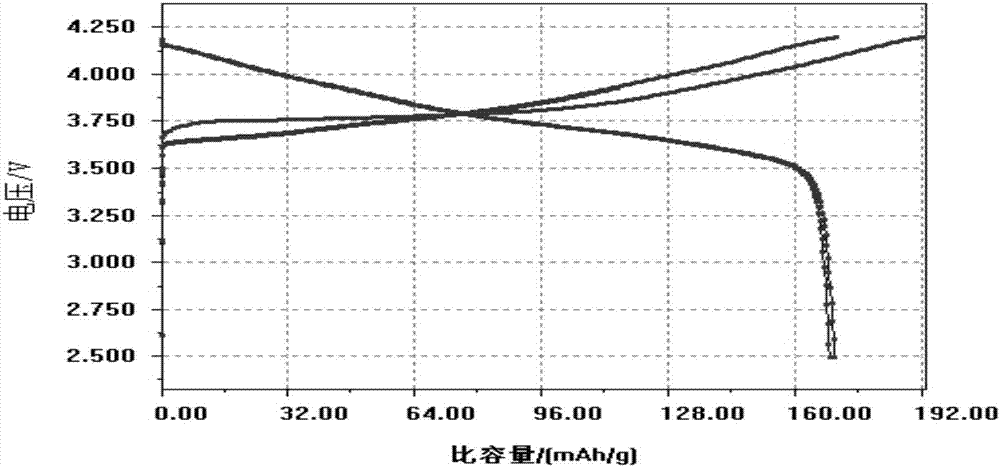

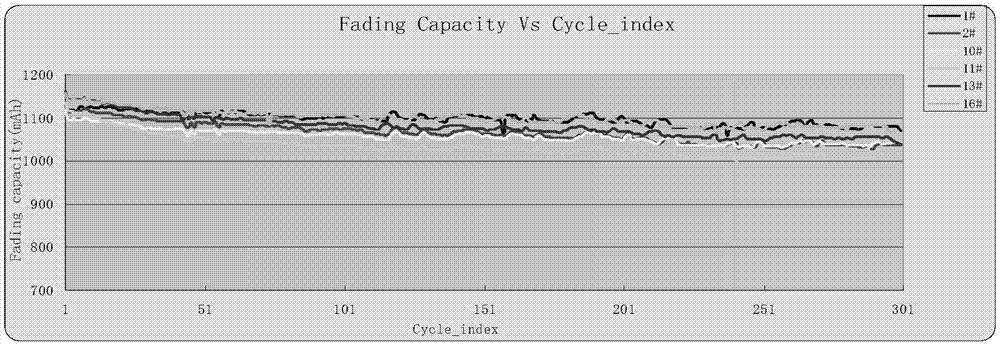

Embodiment 1

[0024] (1) Take 5000 grams of waste nickel-cobalt-lithium-manganese-oxide positive electrode material, pulverize the positive electrode material, then dissolve it with 4mol / L sulfuric acid at a temperature of 60° C., and filter it. The obtained filtrate is nickel, cobalt, manganese, and lithium containing impurities. 36L of mixed metal solution;

[0025] (2) the mixed solution in the step (1) is delivered to the extractant di(2-ethylhexyl) phosphoric acid and phosphonic acid monoester extraction tank containing sulfonated kerosene, so that the calcium, magnesium, iron, copper and zinc in the mixed solution Impurities such as lead and aluminum enter the organic phase of the acidic extractant, and the organic phase loaded with impurities is subjected to multi-stage countercurrent, and the organic phase is back-extracted with acid, so that the organic phase can be regenerated and reused, and impurities such as calcium, magnesium, iron, copper, zinc, lead, and aluminum are removed ...

Embodiment 2

[0029] (1) Get 10,000 grams of waste lithium-ion batteries, disassemble the batteries, take out the positive electrode material and pulverize it, then dissolve it with 6mol / L sulfuric acid at a temperature of 60°C, filter, and the obtained filtrate is nickel, cobalt, manganese, Lithium mixed metal solution 48L;

[0030] (2) the mixed solution in the step (1) is delivered to the extractant di(2-ethylhexyl) phosphoric acid and dialkylphosphonic acid diester extraction tank containing sulfonated kerosene, so that the calcium and magnesium in the mixed solution Impurities such as iron, copper, zinc, lead, and aluminum enter the organic phase of the acidic extractant, and the organic phase loaded with impurities undergoes multi-stage countercurrent, and the organic phase is back-extracted with acid, so that the organic phase can be regenerated and reused, and impurities such as calcium, magnesium, iron, copper, zinc, lead, and aluminum are removed. Removal results in an impurity-fr...

Embodiment 3

[0034] (1) Take 2000 grams of waste nickel-cobalt-lithium-manganese-oxide positive material, pulverize the positive material, then dissolve it with 2mol / L sulfuric acid at a temperature of 60°C, filter, and the obtained filtrate is nickel, cobalt, manganese, lithium containing impurities 16L of mixed solution;

[0035](2) the mixed solution in the step (1) is delivered to the extractant mono(2-ethylhexyl) phosphoric acid and phosphonic acid diester extraction tank containing sulfonated kerosene, so that the calcium, magnesium, iron, copper and zinc in the mixed solution Impurities such as lead and aluminum enter the organic phase of the acidic extractant, and the organic phase loaded with impurities is subjected to multi-stage countercurrent, and the organic phase is back-extracted with acid, so that the organic phase can be regenerated and reused, and impurities such as calcium, magnesium, iron, copper, zinc, lead, and aluminum are removed to obtain Mixed metal solution free ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com