Olive enzyme beverage and production method thereof

A technology of olive enzyme and oleocanthal, which is applied in the field of fermented food, can solve the problems of low utilization rate and low added value, achieve the effects of short production cycle, increase product added value, and soft bitter taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

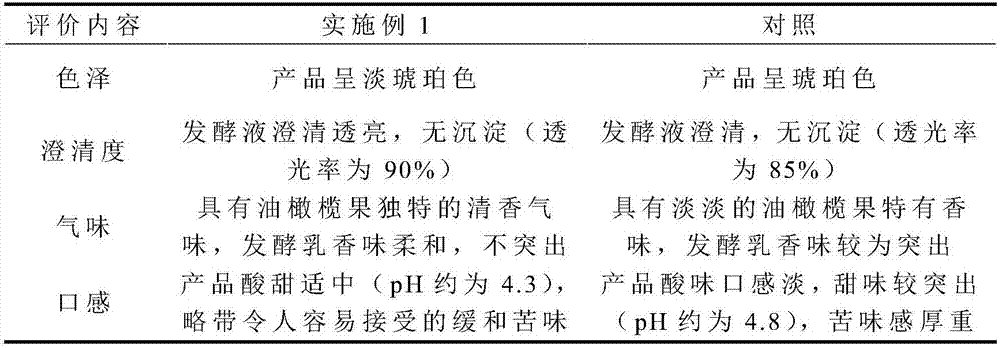

Examples

Embodiment 1

[0025] Formula: 55 parts of olive pomace, 40 parts of drinking water, 4 parts of raw linden honey, 0.2 parts of lactobacillus starter, 15 parts of fructose syrup.

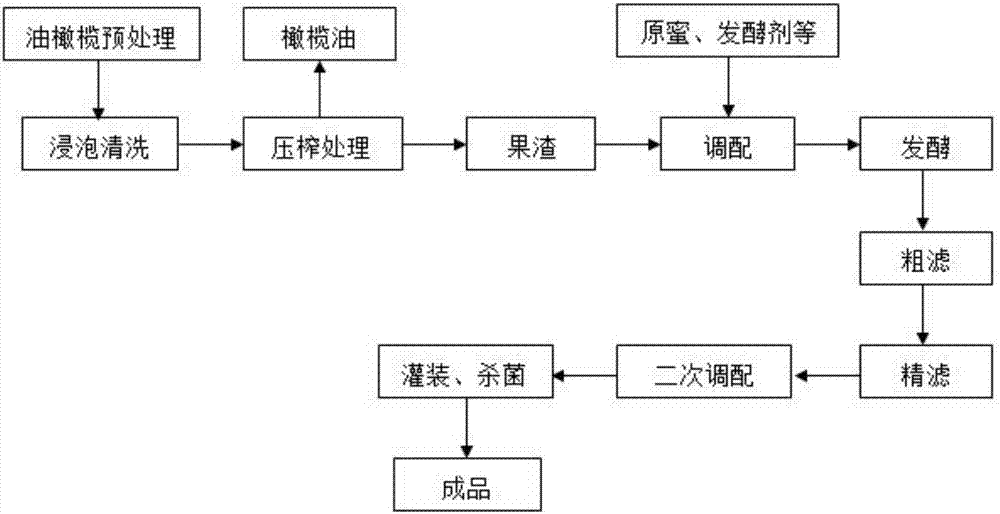

[0026] Method for making oleocanthal enzyme drink (according to the above-mentioned added mass parts), such as figure 1 As shown, the specific steps are:

[0027] 1) Olive pretreatment: remove rotten fruit and moldy fruit in olive fruit, remove stems, leaves and sundries;

[0028] 2) Soak and clean the olives: first wash twice with pure water to remove surface sludge and impurities, then soak with 0.9% normal saline for 20-30 minutes, finally rinse twice with clean water, and drain the water.

[0029] 3) Olive oil processing and pomace acquisition: the olive oil is prepared by low-temperature screw pressing, and the olive pomace is obtained for later use.

[0030] 4) Lactobacillus starter: Lactobacillus starter is obtained by mixing Lactobacillus casei, Lactobacillus acidophilus and Lactobacillus rhamnosus. The ...

Embodiment 2

[0047] Prepare oleocanthal enzyme beverage by the method for embodiment 1, difference is, formula is: 50 parts of olive pomace, 45 parts of drinking water, 2 parts of linden raw honey, 0.2 part of lactobacillus starter, 10 parts of fructose syrup (according to fermentation filtrate percent weight).

Embodiment 3

[0049] Prepare the olive enzyme beverage by the method of embodiment 1, difference is, formula is: 60 parts of olive pomace, 36 parts of drinking water, 3 parts of linden raw honey, 0.15 part of lactobacillus starter, 10 parts of fructose syrup (according to fermentation filtrate percent weight).

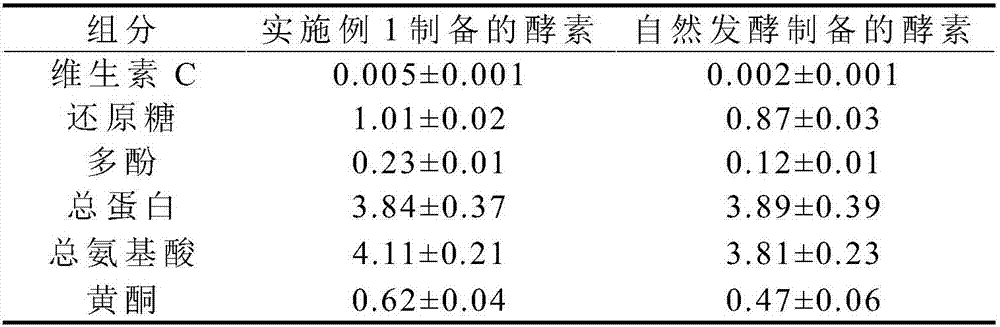

[0050] The content of basic components and functional factors in the enzyme drinks prepared in Examples 2 and 3 were tested, and the results showed that more than 95% of the indicators could reach the level of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com