A method for preparing low-fired composite cement by using waste concrete cement stone phase

A technology for waste concrete and composite cement, applied in cement production, clinker production and other directions, can solve the problems of low strength of dewatered cement stone cementing system, unable to form mechanical properties, affecting cementing ability, etc., achieving low cost of raw materials, eliminating the need for The problem of sticky ball sticking and grinding, the effect of high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of low-fired composite cement

[0029] Use waste concrete cement stone phase to prepare low-fired composite cement. The composition and mass percentage of the cement raw materials are as follows: dehydrated cement stone powder 57%, dihydrate gypsum 3%, dihydrate gypsum 2%, mineral powder 28%, fly ash 10% .

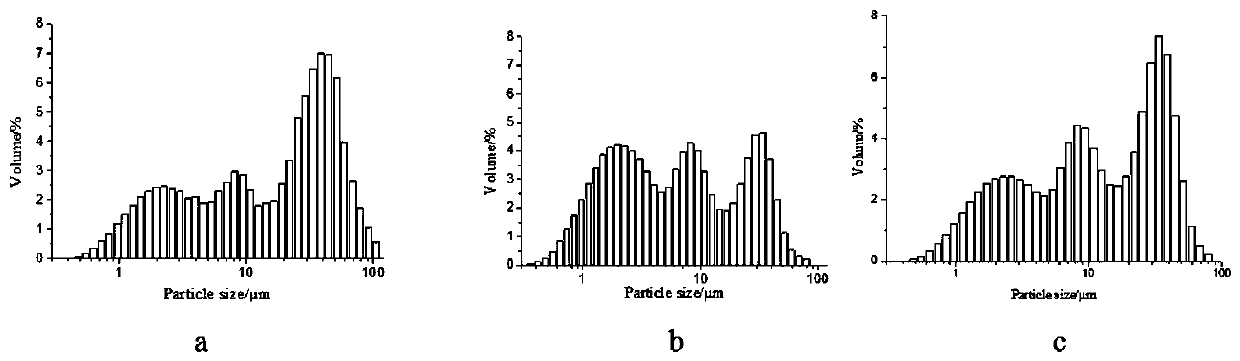

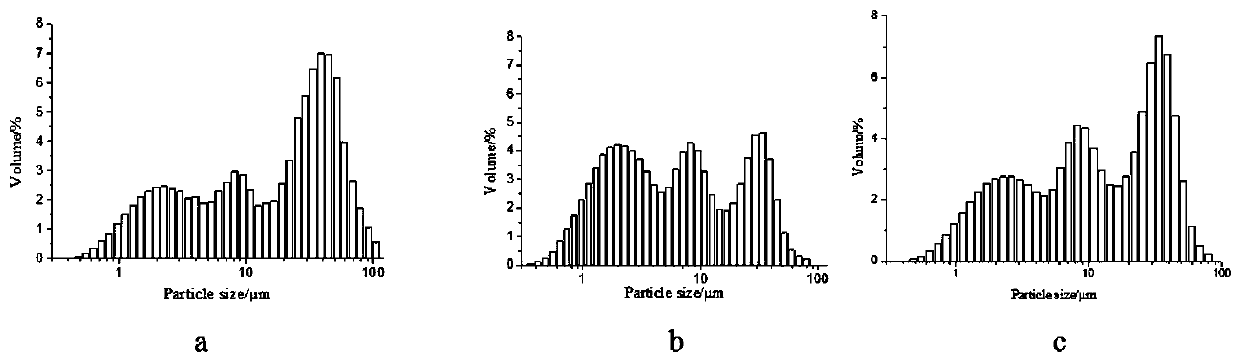

[0030] The preparation process: the hardened cement stone powder separated from the waste concrete is calcined at a low temperature of 700 ° C for 1 hour to obtain dehydrated cement stone powder; the dehydrated cement stone powder is mixed with the above-mentioned raw materials according to the formula ratio and ground until the particle size exceeds 0.08 mm square hole sieve not more than 2%, specific surface area not less than 400m 2 / kg, that is, the low-fired composite cement. It is measured that the cement passes through a 0.08mm square hole sieve with a residue of 1.6% and a specific surface area of 410m 2 / kg. At the same time, the pure d...

Embodiment 2

[0041] Example 2 is basically the same as Example 1, except that the composition of cement raw materials and their mass percentages are: 50% of dehydrated cement stone powder, 5% of dihydrate gypsum, 3% of sodium sulfate, 40% of mineral powder, and 2% of red mud. %. The calcination time is 30min, and the calcination temperature is 800℃

Embodiment 3

[0042] Example 3 is basically the same as Example 1, except that the cement raw material composition and its mass percentage are: 70% of dehydrated cement stone powder, 2% of dihydrate gypsum, 1.5% of sodium sulfate, 25% of mineral powder, tailings sand or Coal gangue or quarry crushed stone chips 1.5%. The calcination time is 1.5h, and the calcination temperature is 600°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com