Preparation method of organic silicone additive and application of organic silicone additive in water-based acrylic semi-gloss resin emulsion

A technology of organic silicon additives and water-based acrylic acid, which is applied in the field of chemical engineering, can solve the problems of affecting the matting effect, the precipitation and flocculation of matting agents, etc., and achieve the effect of simple post-processing, simplified production process, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

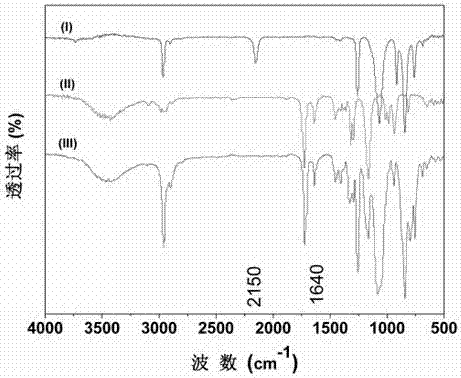

[0033] (1) In a 50ml three-neck flask equipped with a stirrer, a thermometer, a nitrogen pipe and a condensing reflux device, add 0.1g of 2,6-di-tert-butyl-p-cresol, 10ml of allyl methacrylate, and 30ul of platinum. 0.008g / ml chloroplatinic acid isopropanol solution, blow dry nitrogen, stir, heat up to 75°C, add 23ml 1,1,1,3,5,5,5-heptamethyltrisiloxane dropwise, 35min Drop left and right, cool down to room temperature, and filter through a 0.45um nylon filter membrane to obtain silicone additives. The conversion rate of 1,1,1,3,5,5,5-heptamethyltrisiloxane is 77.04%. .

[0034] (2) The polyacrylate emulsion is synthesized according to the formula shown in Table 1. The process is as follows: dissolve 3 / 5 of the emulsifier in deionized water, add all the monomers, and emulsify it into a uniform pre-emulsion under strong stirring . Add deionized water, sodium bicarbonate and the remaining emulsifier into a four-neck flask equipped with a stirrer, thermometer, condenser tube an...

Embodiment 2

[0043] (1) In a 50ml three-neck flask equipped with a stirrer, a thermometer, a nitrogen pipe and a condensing reflux device, add 0.1g of 2,6-di-tert-butyl-p-cresol, 10ml of allyl methacrylate, and 30ul of platinum. 0.008g / ml chloroplatinic acid isopropanol solution, blow dry nitrogen, stir, heat up to 85°C, add 23ml 1,1,1,3,5,5,5-heptamethyltrisiloxane dropwise, 35min Drop left and right, cool down to room temperature, and filter through a 0.22um nylon filter membrane to obtain silicone additives. The conversion rate of 1,1,1,3,5,5,5-heptamethyltrisiloxane is 81.77% .

[0044] (2) The polyacrylate emulsion is synthesized according to the formula shown in Table 1. The process is as follows: dissolve 3 / 5 of the emulsifier in deionized water, add all the monomers, and emulsify it into a uniform pre-emulsion under strong stirring . Add deionized water, sodium bicarbonate and the remaining emulsifier into a four-neck flask equipped with a stirrer, thermometer, condenser tube and...

Embodiment 3

[0046] (1) In a 50ml three-neck flask equipped with a stirrer, a thermometer, a nitrogen pipe and a condensing reflux device, add 0.1g of 2,6-di-tert-butyl-p-cresol, 10ml of allyl methacrylate, and 30ul of platinum. 0.008g / ml chloroplatinic acid isopropanol solution, blow dry nitrogen, stir, heat up to 85°C, add 20ml 1,1,1,3,5,5,5-heptamethyltrisiloxane dropwise, 35min Drop left and right, cool down to room temperature, and filter through a 0.22um nylon filter membrane to obtain silicone additives. The conversion rate of 1,1,1,3,5,5,5-heptamethyltrisiloxane is 81.94%. .

[0047] (2) The polyacrylate emulsion is synthesized according to the formula shown in Table 1. The process is as follows: dissolve 3 / 5 of the emulsifier in deionized water, add all the monomers, and emulsify it into a uniform pre-emulsion under strong stirring . Add deionized water, sodium bicarbonate and the remaining emulsifier into a four-neck flask equipped with a stirrer, thermometer, condenser tube an...

PUM

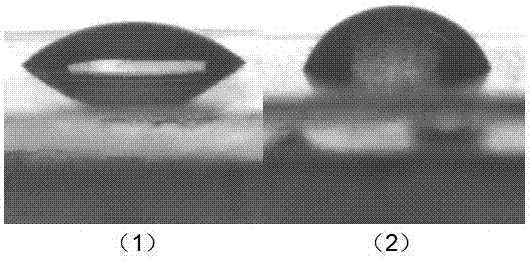

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com