Air Conditioning Compressor Drive Using Engine Waste Heat

A technology for air-conditioning compressors and driving devices, which is applied to machines that use waste heat, engine components, combustion engines, etc., and can solve problems such as increased fuel consumption, worsened engine emissions, and economic decline, and achieves reduced losses, reduced impacts, and savings energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

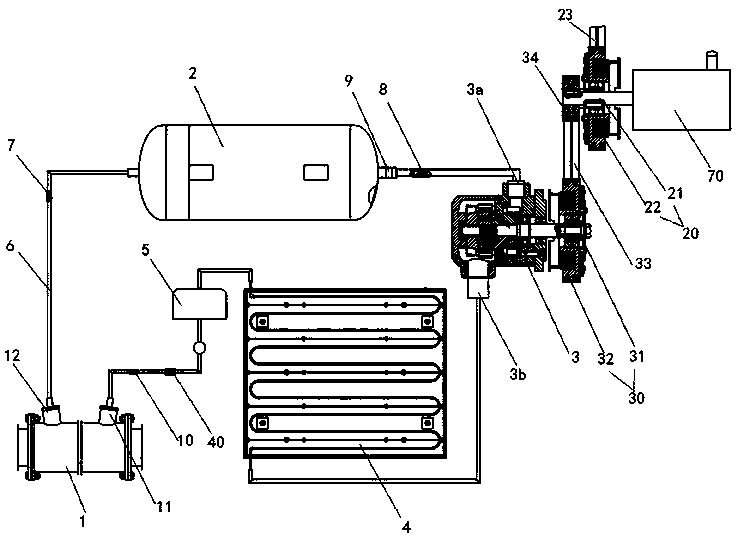

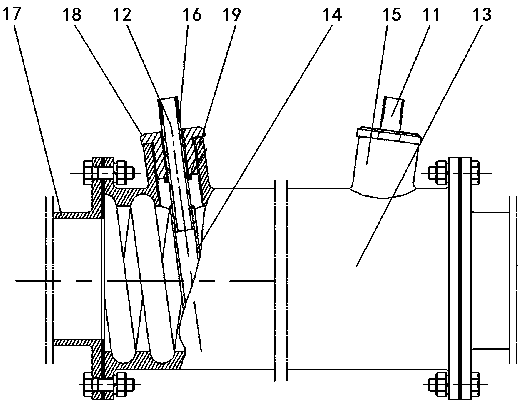

[0019] Please combine figure 1 with figure 2 As shown, the air conditioner compressor driving device using engine waste heat includes a carburetor 1, an air storage tank 2, an air motor 3, a condenser 4, a liquid storage tank 5 and working fluid. The vaporizer 1 is a key component for vaporizing the working fluid from the liquid state by absorbing the waste heat of the engine, and it includes a connecting straight pipe 13 and a spiral pipe 14 . Both ends of the connecting straight pipe 13 are fixedly connected with the original automobile exhaust pipe 17 by bolts. In order to ensure a good vaporization effect, an austenitic stainless steel tube is used to wind a helical tube 14. The inner diameter or small diameter of the helical tube 14 is the same as that of the original exhaust pipe 17, so that it does not affect the exhaust b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com