A lithium-ion battery cell baking and drying production line

A lithium-ion battery and cell baking technology, which is applied in drying, dryers, progressive dryers, etc., can solve the problem of ineffective removal of water vapor, air and impurities, affecting the consistency of cells, and poor temperature uniformity and other issues, to achieve the effect of improving baking reliability, improving automation level, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

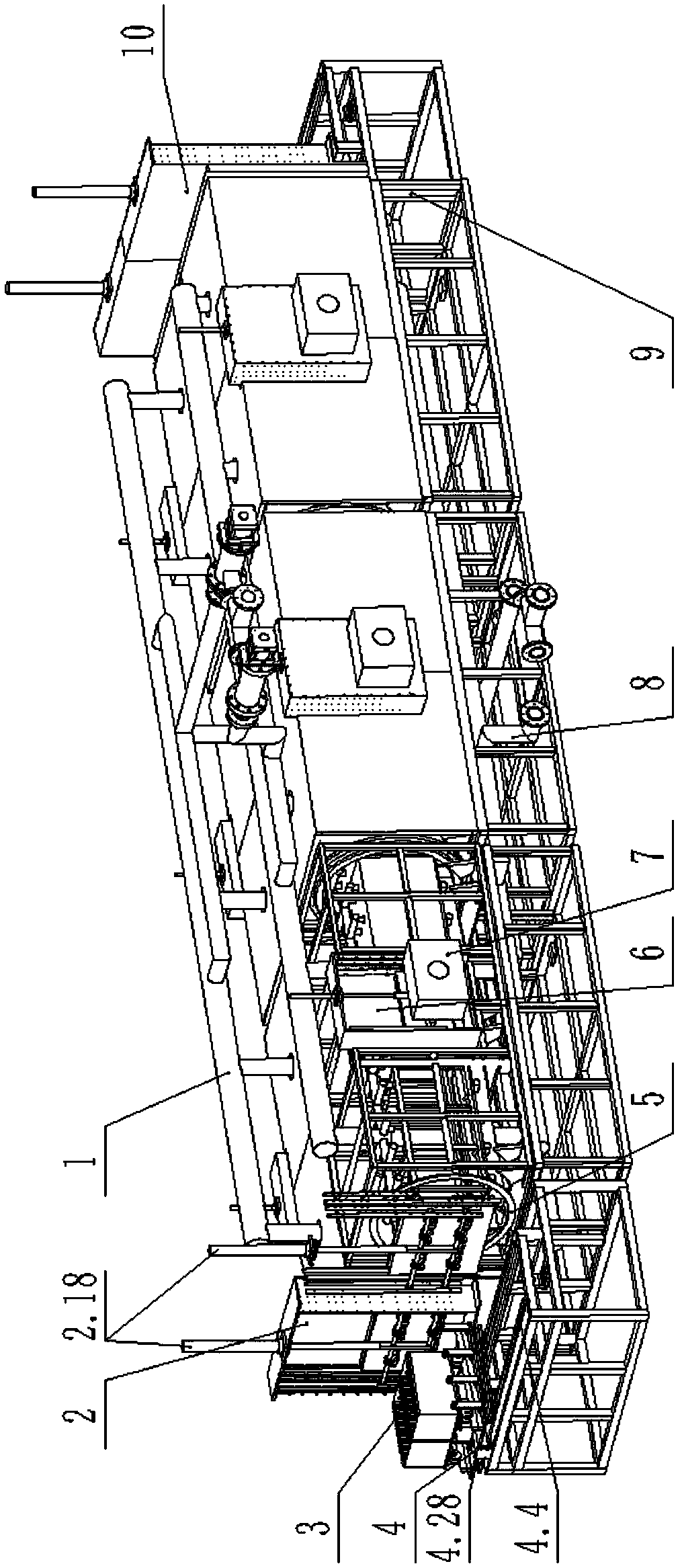

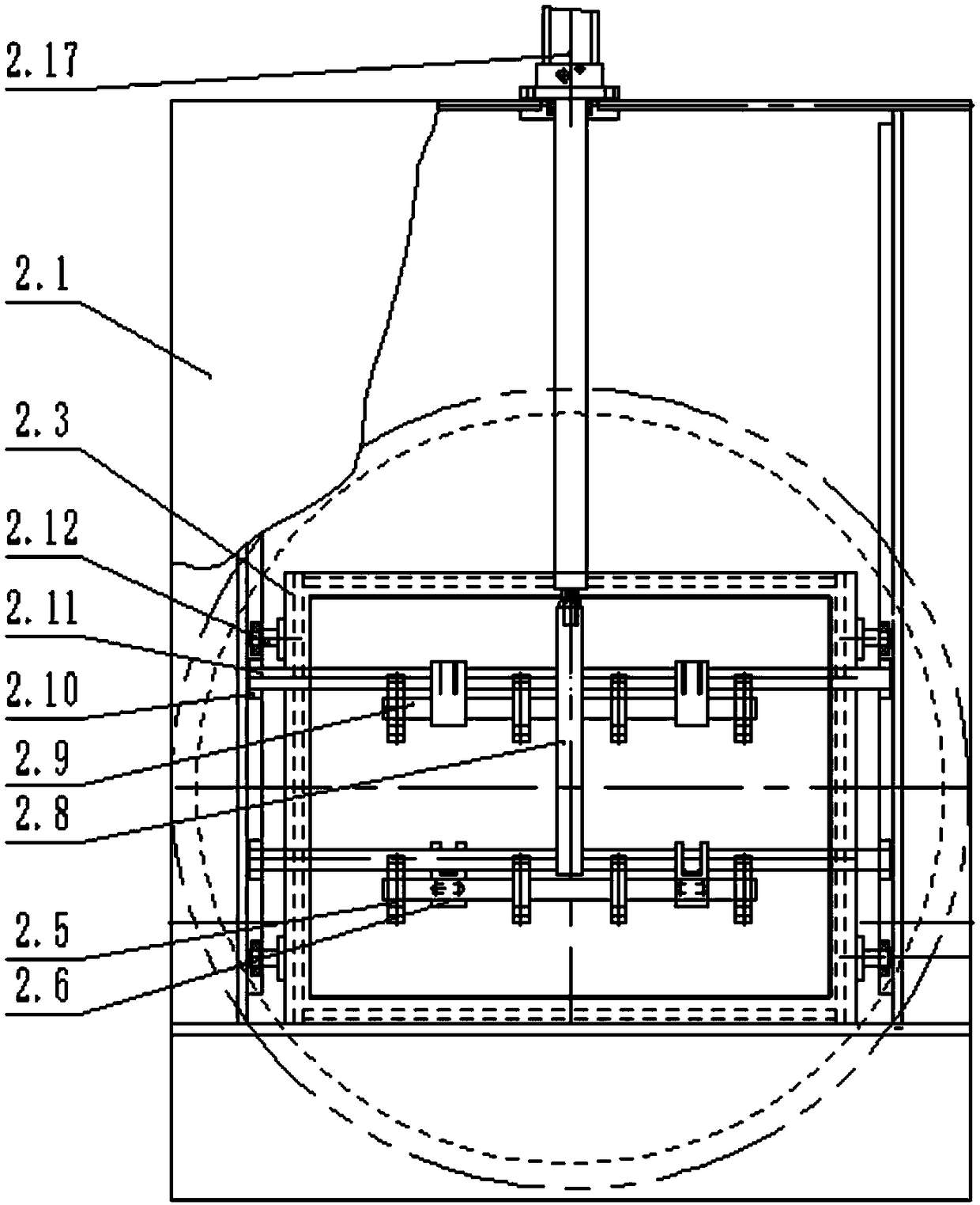

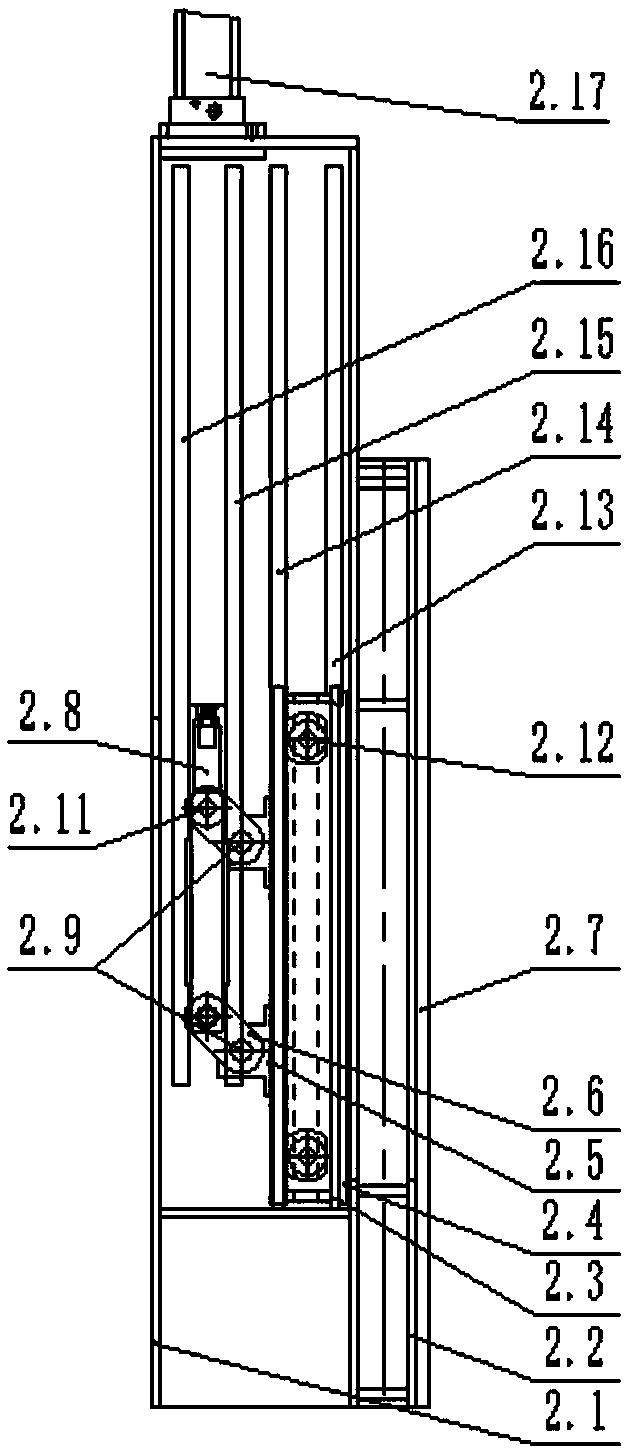

[0024]The invention provides a lithium-ion battery cell baking and drying production line (referred to as the production line, see Figure 1-6 ), including nitrogen circulation pipes 1, two sets of front doors and windows 2, at least two sets of cell trolleys 3, two sets of left and right car transport devices 4, two sets of inner linings 5, at least two sets of side doors and windows 6, at least two sets of glove boxes 7 , vacuum pipe 8, frame 9 and two groups of rear doors and windows 10; the structure of described front doors and windows 2, side doors and windows 6 and rear doors and windows 10 is identical; A group of left and right car transport devices 4 cooperate with two groups of rear doors and windows 10;

[0025] One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com