Measuring device and method for free-form surface based on metallic silver enhanced fluorescence

A technology for enhancing fluorescence and measuring devices, applied in measuring devices, adopting optical devices, instruments, etc., can solve the problems of uneven fluorescent interlayer and large surface height error, so as to reduce measurement cost, small surface height error, The effect of simple light path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

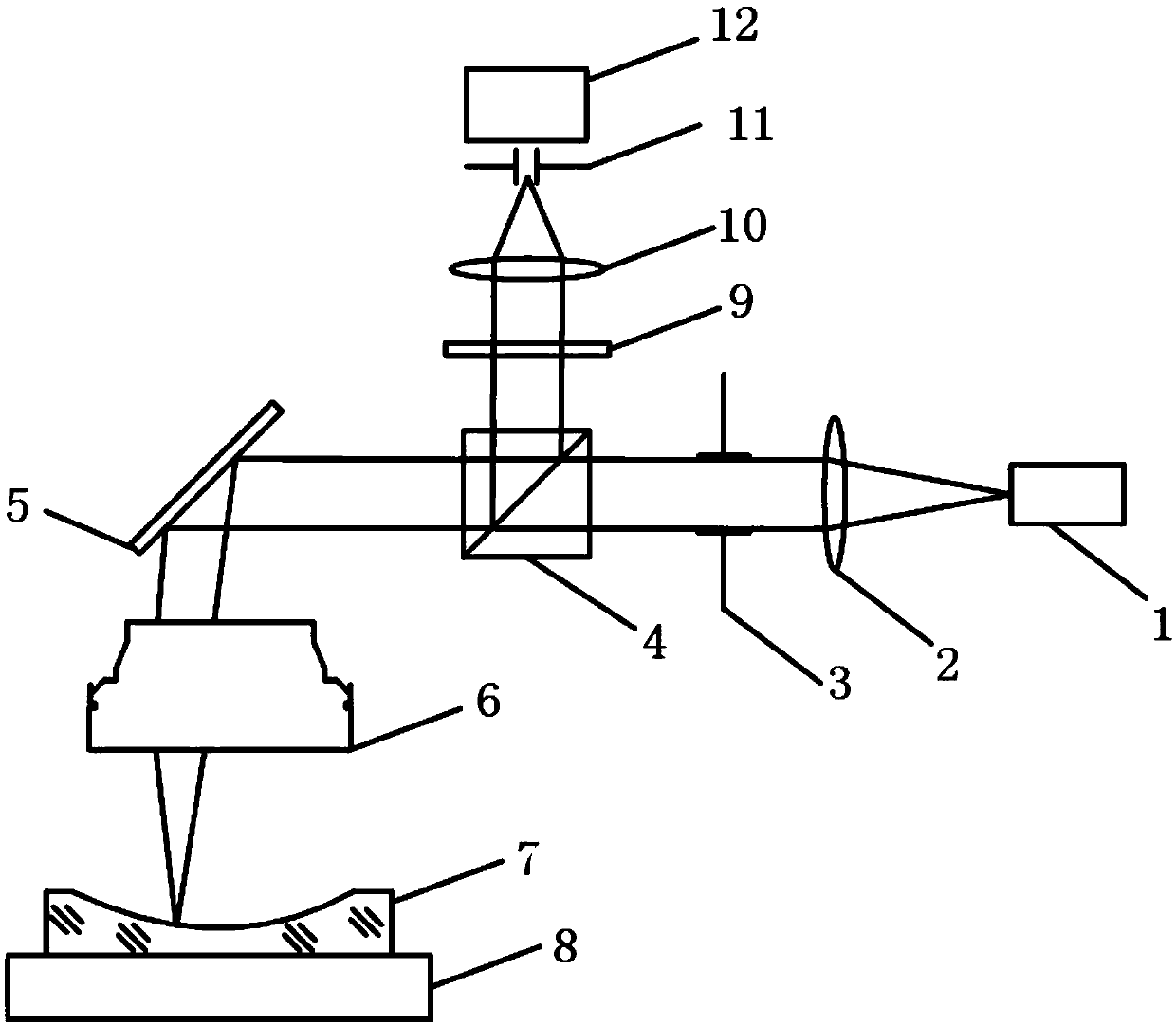

[0018] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the free-form surface measurement device based on metallic silver enhanced fluorescence described in this embodiment, the measurement device includes an illumination module, a detection module and a sample module;

[0019] According to the propagation direction of the illumination light, the illumination module is as follows: laser 1, collimator 2, aperture 3, polarization beam splitter prism 4, scanning galvanometer 5 and scanning lens 6;

[0020] According to the signal light propagation direction, the detection module is as follows: scanning lens 6, scanning galvanometer 5, polarization beam splitter prism 4, optical filter 9, collecting lens 10, pinhole 11 and photodetector 12;

[0021] The sample module includes a sample to be tested 7 and a three-dimensional micro-displacement stage 8 for placing the sample to be tested 7;

[0022] The surface of the sample to be tested...

specific Embodiment approach 2

[0024] Specific implementation mode two: the following combination figure 1 This embodiment will be described. This embodiment will further describe the first embodiment. The scan lens 6 is used as an illumination and imaging lens, and has a field of view of 50 mm×50 mm.

specific Embodiment approach 3

[0025] Specific implementation mode three: the following combination figure 1 This embodiment will be described. This embodiment will further describe Embodiment 1. The wavelength of the laser beam emitted by the laser 1 is 532nm, and the optical power of the illumination light after passing through the scanning lens 6 is less than 1w.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com