Gallium-nitride-based inverter chip and forming method therefor

A gallium nitride based, inverter technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of low operating frequency, poor transmission, low frequency band, etc. On-resistance, effect of wide operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the gallium nitride-based inverter chip and its forming method provided by the present invention will be described in detail below with reference to the accompanying drawings.

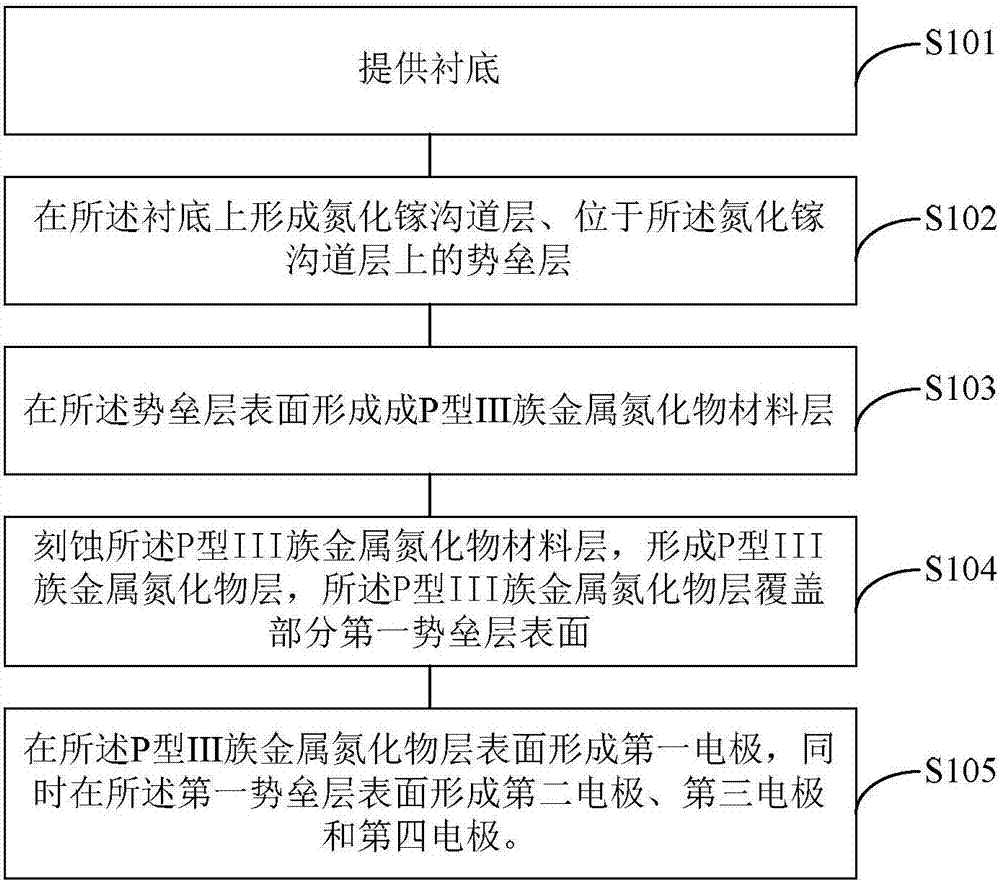

[0021] Please refer to figure 1 , is a schematic flowchart of a method for forming a GaN-based inverter chip according to a specific embodiment of the present invention.

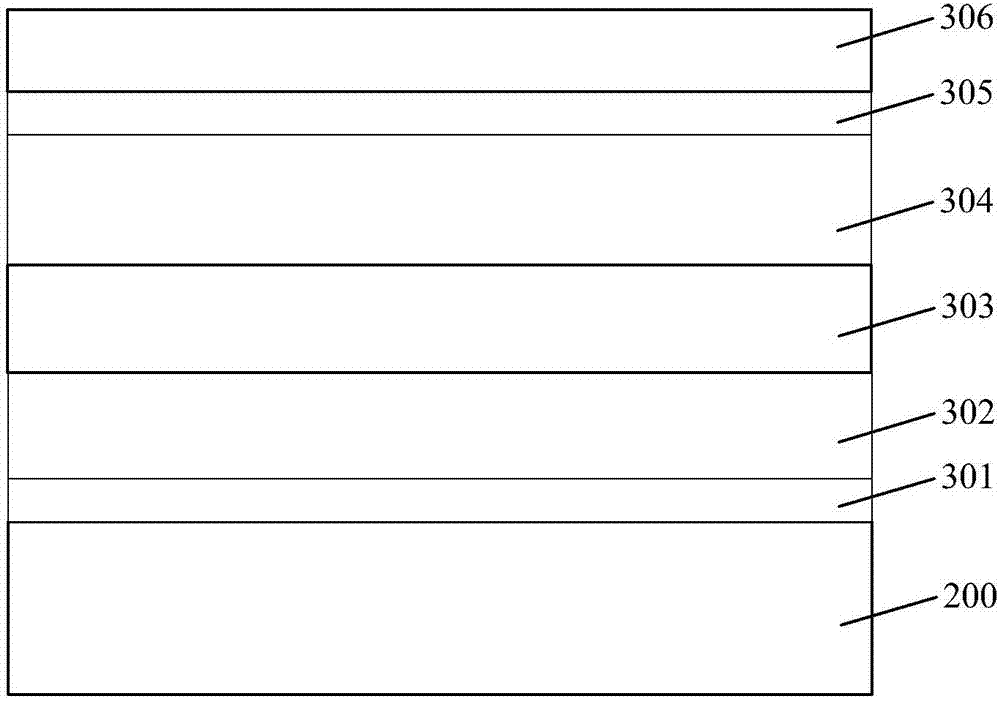

[0022] The method for forming the gallium nitride-based inverter chip includes: step S101: providing a substrate; step S102: forming a gallium nitride channel layer on the substrate, and forming a gallium nitride channel layer on the gallium nitride channel layer Barrier layer; step S103: forming a p-type group III metal nitride material layer on the surface of the barrier layer; step S104: etching the p-type group III metal nitride material layer to form a p-type group III metal nitride material layer layer, the P-type Group III metal nitride layer covers part of the surface of the barrier laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com