Preparation method of nickel-cobalt CNT (carbon nano tube) aerogel zinc-air battery catalyst

A carbon nanotube and zinc-air battery technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve problems such as high price, hidden safety hazards in lithium cobalt oxide batteries, and lack of cobalt resources, etc., to achieve Good stability, ultra-fine particles, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

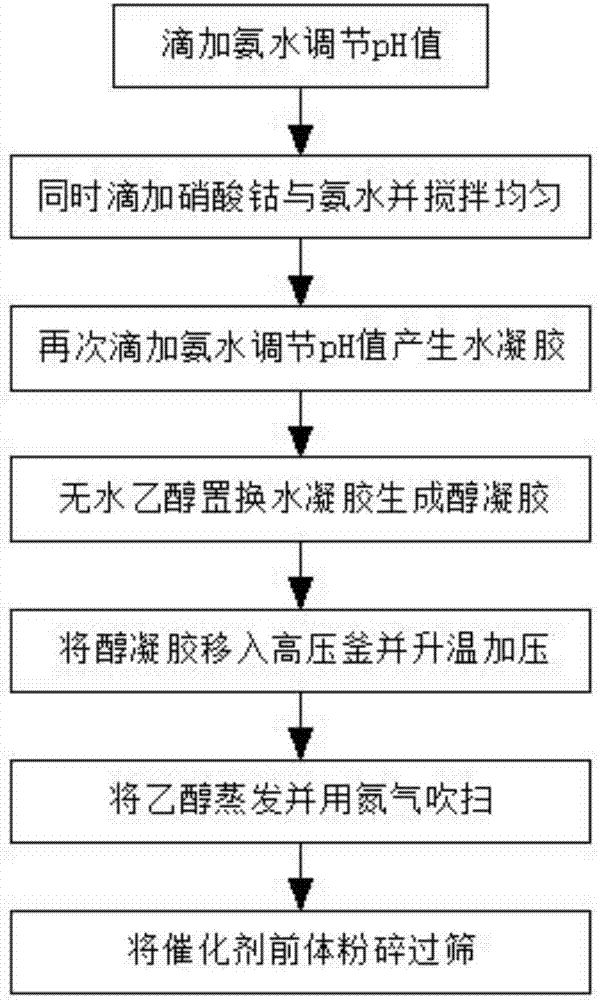

[0020] A method for preparing a nickel-cobalt carbon nanotube airgel zinc-air battery catalyst, the specific steps of the preparation method of the nickel-cobalt / carbon nanotube airgel zinc-air battery catalyst are as follows:

[0021] S1: Add ammonia water dropwise to the 0.2mol / l metal nickel solution under strong stirring at room temperature, stop adding ammonia water when the pH value of the mixed solution is 7.5, and use the displacement precipitation method to dissolve the metal nickel solution into the solution before the reaction. filter out impurities;

[0022] S2: Add dropwise 0.2mol / l cobalt nitrate solution and ammonia water to the mixed solution at the same time, and stir for 15 minutes;

[0023] S3: adding ammonia water dropwise to maintain the pH value of the mixed solution at 8.5, and stirring and standing still, a hydrogel is formed in the mixed solution, and the stirring and standing time are each 3 hours;

[0024] S4: Use absolute ethanol to replace the wat...

Embodiment 2

[0029] A method for preparing a nickel-cobalt carbon nanotube airgel zinc-air battery catalyst, the specific steps of the preparation method of the nickel-cobalt / carbon nanotube airgel zinc-air battery catalyst are as follows:

[0030] S1: Add ammonia water dropwise to the 0.4mol / l metal nickel solution under strong stirring at room temperature, and stop adding ammonia water when the pH value of the mixed solution is 7.5. filter out impurities;

[0031] S2: Add 0.4mol / l cobalt nitrate solution and ammonia water dropwise to the mixed solution at the same time, and stir for 20 minutes;

[0032] S3: adding ammonia water dropwise to maintain the pH value of the mixed solution between 9, and stirring and standing still, a hydrogel is formed in the mixed solution, and the stirring and standing time are each 3 hours;

[0033] S4: Use absolute ethanol to replace the water in the hydrogel until the water content in the filtrate is detected by gas chromatography to be lower than 5%, an...

Embodiment 3

[0038] A method for preparing a nickel-cobalt carbon nanotube airgel zinc-air battery catalyst, the specific steps of the preparation method of the nickel-cobalt / carbon nanotube airgel zinc-air battery catalyst are as follows:

[0039] S1: Add ammonia water dropwise to the 0.3mol / l metal nickel solution under strong stirring at room temperature, stop adding ammonia water when the pH value of the mixed solution is 7.5, and use the displacement precipitation method to dissolve the metal nickel solution into the solution before the reaction. filter out impurities;

[0040] S2: Add 0.3 mol / l cobalt nitrate solution and ammonia water dropwise to the mixed solution at the same time, and stir for 18 minutes;

[0041] S3: adding ammonia water dropwise to maintain the pH value of the mixed solution at 8.7, and stirring and standing still, a hydrogel is formed in the mixed solution, and the stirring and standing time are each 3 hours;

[0042] S4: Use absolute ethanol to replace the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com