A reacting method for fluidized beds for preparing hydrocarbons from methanol

A fluidized bed reaction and fluidized bed reaction zone technology, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve problems such as increased investment and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

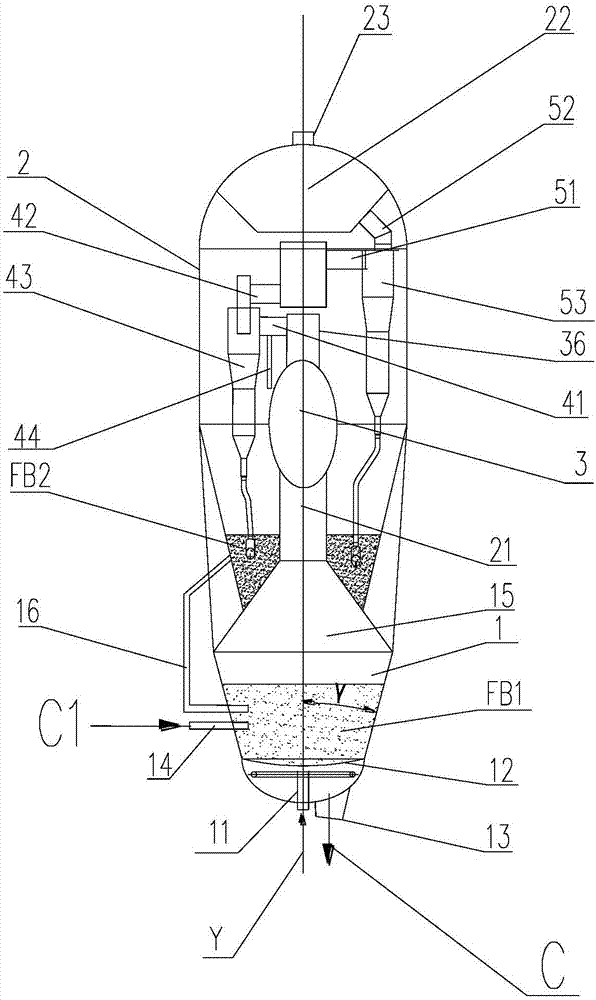

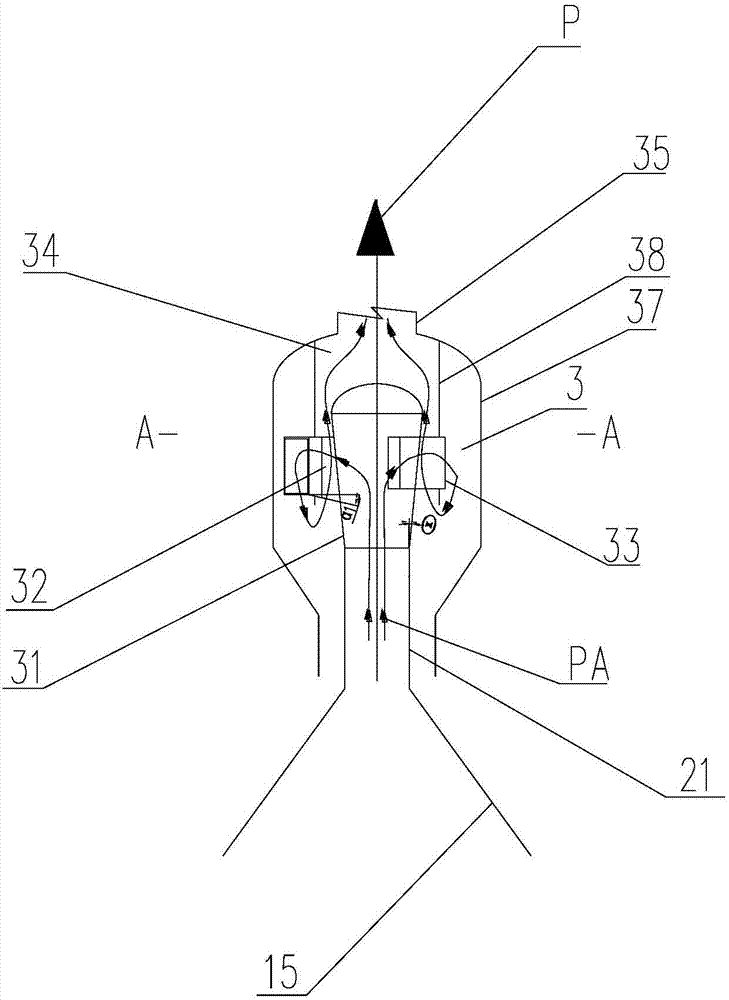

[0032] Such as figure 1 As shown, the methanol-to-hydrocarbon fluidized bed reaction method of the present invention is provided with a fluidized bed reaction zone FB1 at the bottom and a post-reaction treatment zone at the top; the post-reaction treatment zone is provided with a shell 2, a reaction gas accumulation zone 15, Reaction termination controller 3 and gas-solid separation zone;

[0033] The fluidized bed reaction zone FB1 uses a conical fluidized bed reactor 1, the catalyst forms a conical fluidized bed in the conical fluidized bed reactor 1, and the area of the conical fluidized bed reactor 1 gradually increases along the flow direction of the reaction raw material Y. Expansion, conical fluidized bed reactor 1 semi-cone angle γ is 0 ~ 30°; correspondingly reduce the velocity of gas leaving the fluidized bed, reduce the amount of catalyst carried; above the fluidized bed reaction zone FB1 react in the conical fluidized bed A tapered reaction gas accumulation area...

Embodiment approach 2

[0044] Such as Figure 6 As shown, the methanol-to-hydrocarbon fluidized bed reaction method of the present invention is provided with a fluidized bed reaction zone at the bottom and an upper post-reaction treatment zone; the post-reaction treatment zone is provided with a shell, a reaction gas accumulation zone, and a reaction termination control Device 3 and gas-solid separation zone;

[0045] A catalyst controller integrating catalyst heat extraction and circulating catalyst stripping is arranged on the pipeline at the outlet of the catalyst to be used. The circulating catalyst stripper 62 and the catalyst heat extractor 61 are arranged in series up and down; the catalyst heat extractor 61 uses water or methanol raw material as Take the heat medium, this embodiment uses water as the heat take medium to generate medium-pressure saturated steam, and the water vapor separator 63 is connected with the catalyst heat taker 61 as a whole;

[0046] In the fluidized bed reaction zo...

Embodiment

[0051] Methanol to olefins reaction. The methanol feed is 1.8 million tons / year, and the products are ethylene and propylene.

[0052] Reaction condition parameters:

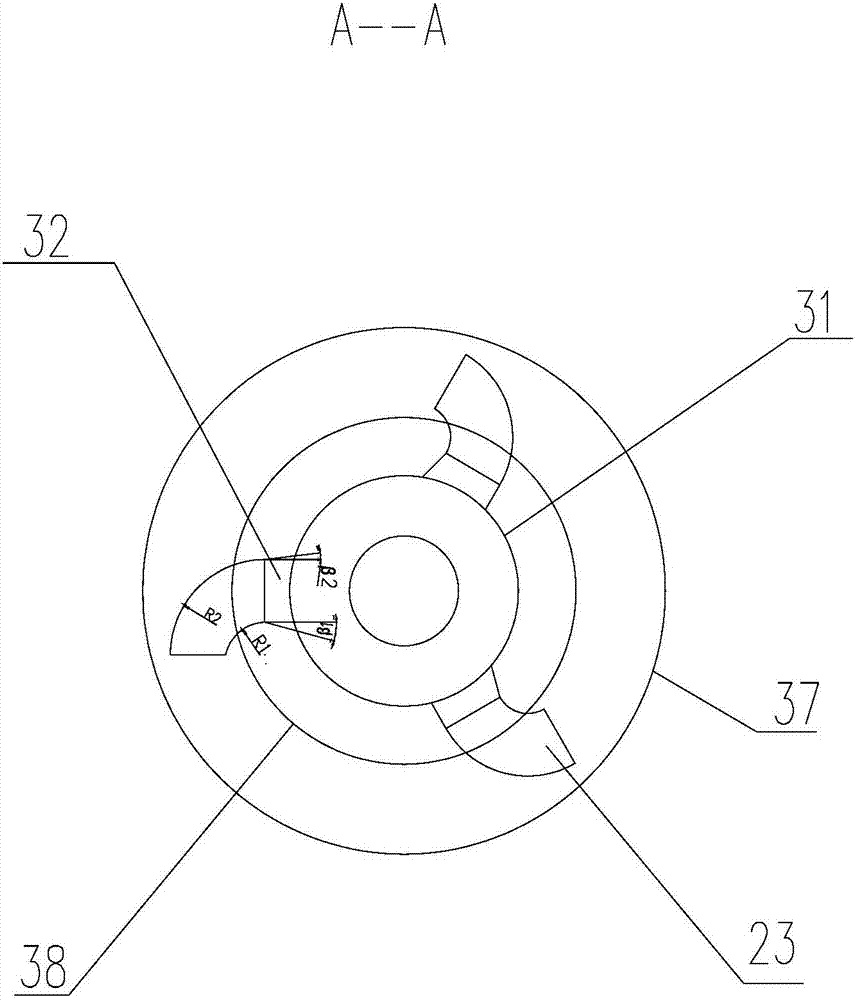

[0053] The reaction time is 2.5 seconds, the reaction temperature is 495°C, the reaction pressure is 0.13MPaG, the superficial flow velocity of the conical fluidized bed gas is 0.8 m / s, and the gas residence time from the conical fluidized bed layer to the center of the cyclone inlet is 4 seconds, Catalyst in and out is 80 tons / hour, and the catalyst bed height of the conical fluidized bed is set at 2 meters above the reaction raw material feed distributor; the cone angle of the conical fluidized bed reactor is 12°, and the reaction raw material feed distribution The height above the device is 4 meters, the lower edge of the cone of the reaction gas accumulation area is 4 meters away from the reaction raw material feed distributor, the flow rate of the delivery pipe is 12 m / s; the central pipe cone angle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com