Low-temperature high-strength and high-toughness wear-resistant aluminum and bronze alloy and preparing method thereof

A high-strength, high-toughness, aluminum bronze technology, applied in the field of wear-resistant aluminum bronze alloy and its preparation, can solve the problems of low impact toughness of mechanical properties, increased brittleness of aluminum bronze alloy, and reduced service life of parts, etc., to achieve good plastic deformation ability, The effect of improving the service life of the equipment and improving the comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

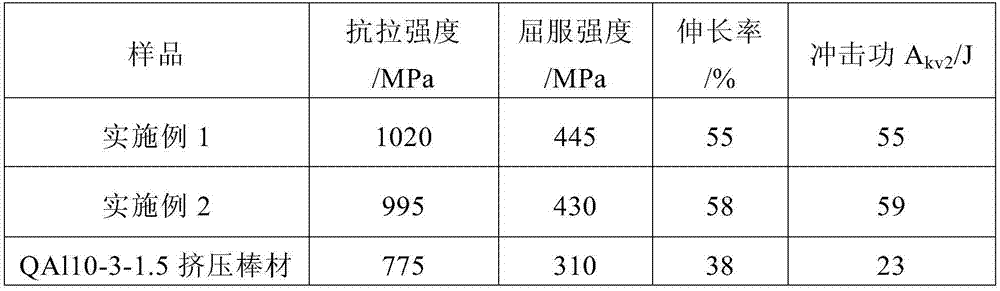

Examples

Embodiment 1

[0023] Its production process is: batching - casting - hot forging - equal channel angular extrusion - finished product

[0024] The specific process is as follows: 84.3% copper, 9.0% aluminum, 2.5% iron, 3.5% nickel, 0.5% manganese, and 0.2% titanium are made into alloy material, which is smelted by medium frequency induction melting furnace. The temperature is 1100-1200°C. The alloy material is added in one go and solvents (glass, cryolite) are added to cover and refine the molten alloy. After standing still and removing slag, it is poured into a Φ200mm ingot. After the ingot wagon is cut to size, it is forged and deformed at a temperature of 850°C. First, it is forged in one direction, with a reduction of 25-30% per pass; then the billet is turned 90°, and the same as the previous one Forging; according to this method, a total of 3 forgings are carried out, with a total reduction of 80%, and finally air-cooled to room temperature to make a copper alloy forging.

[0025] ...

Embodiment 2

[0027] Its production process is: batching - casting - hot forging - equal channel angular extrusion - finished product

[0028] The specific process is as follows: 82.8% copper, 11.0% aluminum, 3.0% iron, 2.5% nickel, 0.5% manganese, and 0.2% titanium are made into alloy material, which is smelted by medium frequency induction melting furnace. The temperature is 1100-1200°C. The alloy material is added in one go and solvents (glass, cryolite) are added to cover and refine the molten alloy. After standing still and removing slag, it is poured into a Φ200mm ingot. After the ingot wagon is cut to size, it is forged and deformed at a temperature of 800°C. First, it is forged in one direction, with a reduction of 20-25% per pass; then the billet is turned 90°, and the same as the previous one Forging; according to this method, a total of 4 forgings are carried out, with a total reduction of 85%, and finally air-cooled to room temperature to make a copper alloy forging.

[0029]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com