Sectional membrane filamentation friction composite spinning method

A composite spinning and friction spinning technology, applied in the field of textiles, can solve the problems of difficulty in uniform mixing and fully cohesion and twisting, difficulty in fully transferring and cohesion, etc., and achieves improved molecular orientation and crystallization, consistent and efficient output, and increased strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

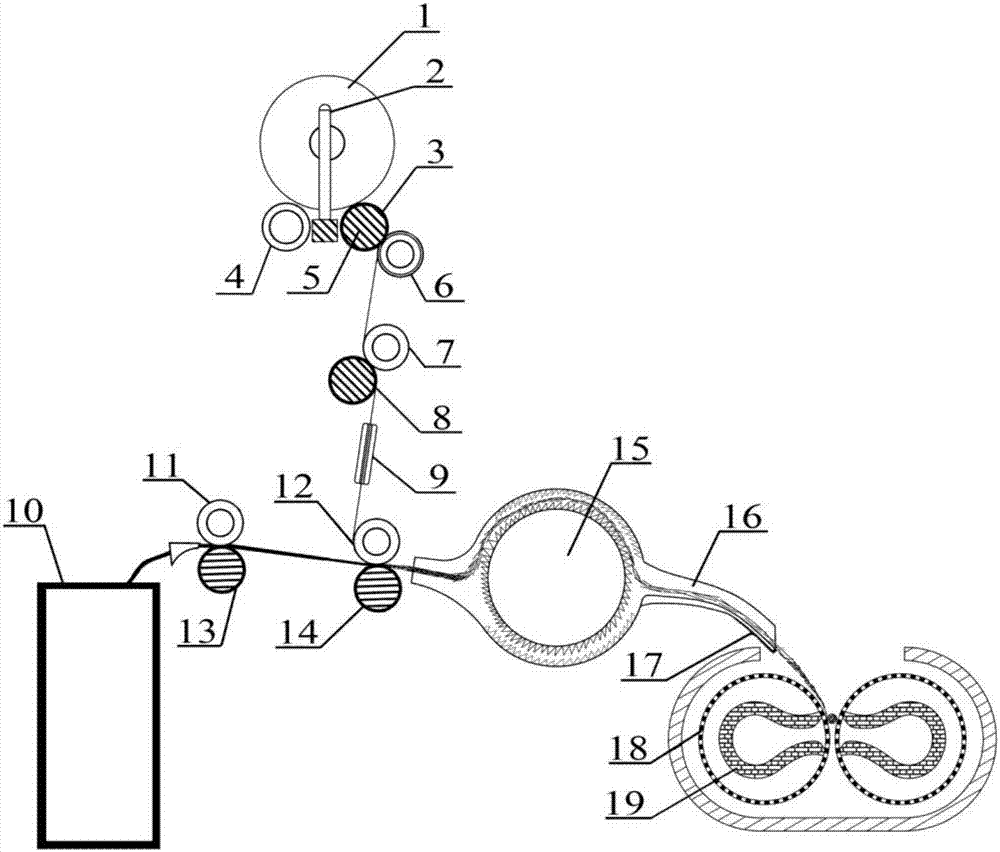

[0020] Using polyamide (nylon) mesh membrane fibrillation and cotton fiber friction composite twisting into yarn.

[0021]The molded membrane material is a polyamide mesh membrane with a width of 15 mm and a thickness of 0.1 mm; the cutting-resistant ring 3 is a high-strength polyethylene cutting-resistant material; the cutting roller 6 is surrounded by adjacent ring cutters. The spacing between the heaters is 0.1mm; the heater 9 is externally connected to a 24-volt safety power supply through the lead wires, and the inner wall of the heating tank of the heater 9 is heated to 150°C; Between the unwinding roller 5 and the unwinding roller 5, the film material unwound from the film material package 1 enters the cutting area formed between the cut-resistant ring 3 and the cutting roller 6 through the unwinding roller 5, and cuts to form a uniformly spread strip-shaped complex. After being output from the cutting area, the silk and ribbon-shaped multifilaments enter the first draw...

Embodiment 2

[0023] Using polysulfone (PSF) nanofiber membrane silk and wool fiber friction compound twisting into yarn.

[0024] The type membrane material is polysulfone (PSF) nanofiber membrane, the nanofiber fineness in the type membrane material is 400-600 nanometers, which belongs to thermoplastic nanofiber membrane material, the width of the membrane material is 20 mm, and the thickness is 0.1 mm; The cut-resistant ring 3 is aramid fiber material; the distance between the edges of the adjacent annular cutters on the circumference of the cutting roller 6 is 3 millimeters; the heater 9 is externally connected to a 36-volt safety power supply through a lead wire, and the inner wall of the heating tank of the heater 12 is Heating to 240°C; place the formed PSF nanofiber membrane material package 1 between the bearing roller 4 and the unwinding roller 5, and the membrane material unwound from the membrane material package 1 enters through the unwinding roller 5 into the The cutting zone ...

Embodiment 3

[0026] Inorganic copper film silking and ramie fiber friction compound twisting are used to form yarn.

[0027] The molded membrane material is a copper thin film, and the molded membrane membrane material width is 10 millimeters, and the thickness is 0.06 millimeters; The cutting-resistant ring 3 is an ultra-high-strength rubber; 1 mm; the heater 9 is externally connected to a 36-volt safety power supply through a lead wire, and the inner wall of the heating tank of the heater 9 is heated to 60 ° C; In between, the film material unwound from the film material package 1 enters the cutting area formed between the cut-resistant ring 3 and the cutting roller 6 through the unwinding roller 5, and is cut to form a uniformly spread ribbon-shaped multifilament. After the silk is output from the cutting area, it enters the first drawing area and the second drawing area in turn, and is drawn once in the first drawing area, and the first drawing ratio is 1.05 times. Heat treatment at 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com