Scratch-resistant super-hydrophobic and oleophylic cellulose oil and water adsorption/separation film and preparation method thereof

A cellulose membrane, scratch-resistant technology, applied in separation methods, grease/oily substance/float removal devices, liquid separation, etc., can solve problems such as lack of mechanical scratch stability, modifier waste, methanol discharge, etc. , to achieve the effect of low price, short time consumption and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

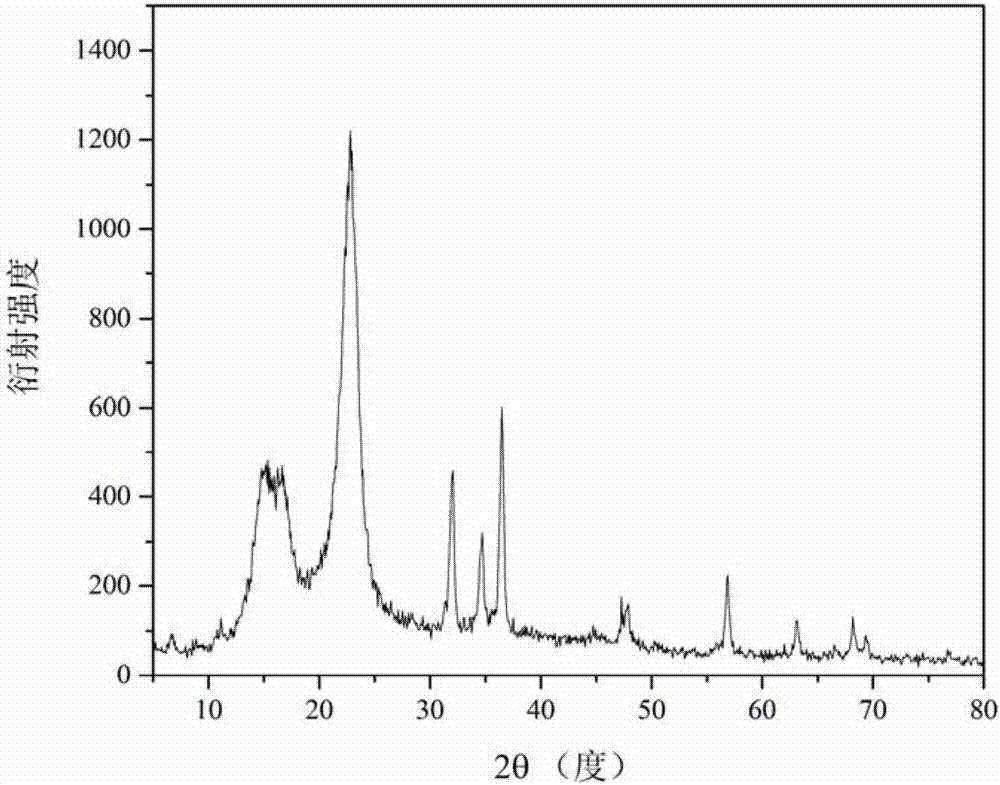

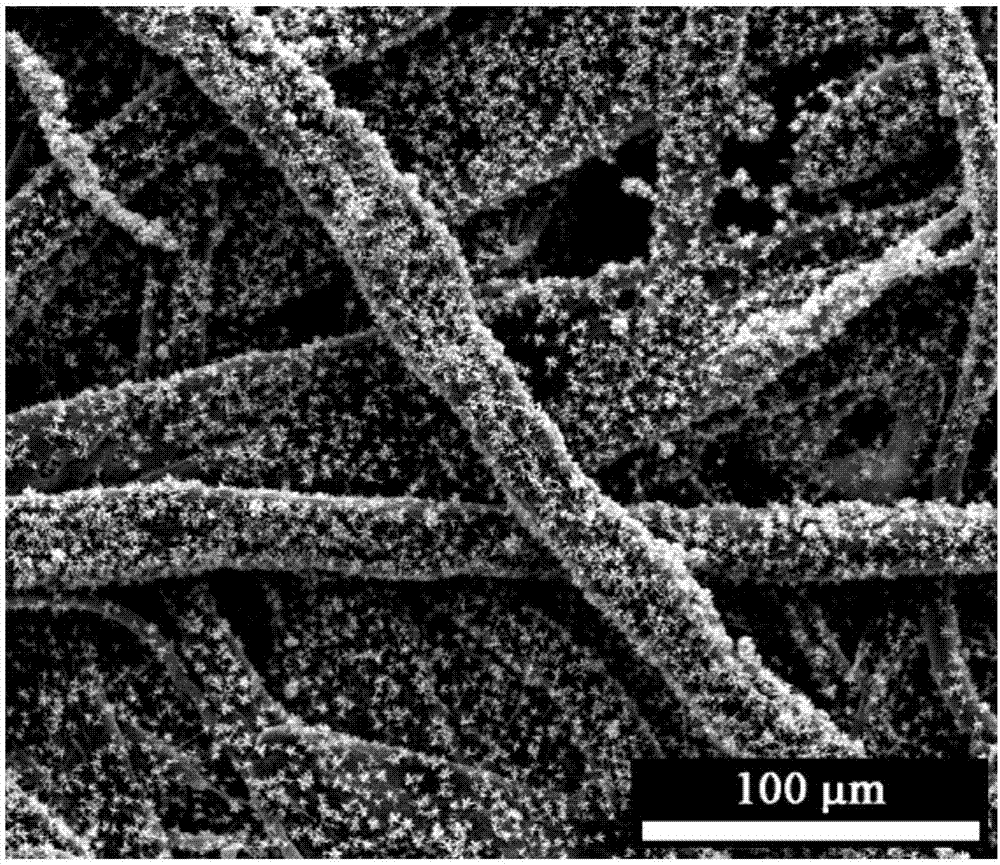

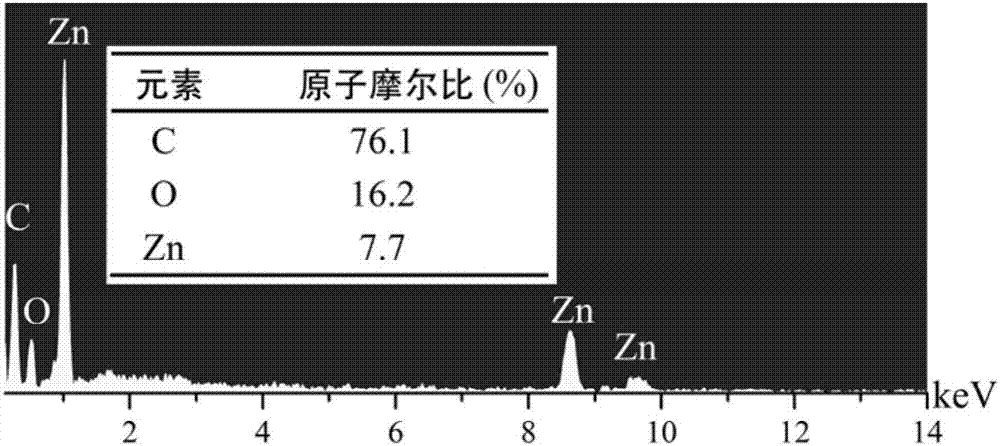

[0034] Add ammonia solution with a mass fraction of 20% to 0.05mol / L zinc nitrate solution and stir to form a mixed solution, so that the molar ratio of zinc atoms to nitrogen atoms is 1:4, then put it into a cellulose membrane and react at 80°C for 4 hours, and the reaction is over Finally, take out the cellulose film and rinse it with deionized water, and dry it under vacuum at 40°C; soak the obtained cellulose film in 0.01mol / L stearic acid ethanol solution at 25°C for 6h, wash it with ethanol after the reaction, and dry it at 40°C °C and vacuum dried.

[0035] The contact angle of the prepared film with water in air is greater than 150°, the water rolling angle is less than 10°, and the contact angle of the prepared film with oil in air is 0°, showing super lipophilicity. After the film is scraped ten times by the blade, its water contact angle is greater than 150°, and its water rolling angle is less than 10°.

Embodiment 2

[0037] Add ammonia solution with a mass fraction of 35% to 0.1mol / L zinc acetate solution and stir to form a mixed solution, so that the molar ratio of zinc atoms to nitrogen atoms is 1:1, then put it into a cellulose film and react at 100°C for 2 hours, and the reaction is over. Finally, take out the cellulose film and rinse it with deionized water, and dry it in vacuum at 40°C; soak the obtained cellulose film in 0.25mol / L stearic acid ethanol solution at 50°C for 1h, wash it with ethanol after the reaction, and dry it at 40°C °C and vacuum dried.

[0038] The contact angle of the prepared film with water in air is greater than 150°, the water rolling angle is less than 10°, and the contact angle of the prepared film with oil in air is 0°, showing super lipophilicity. After the film is scraped ten times by the blade, its water contact angle is greater than 150°, and its water rolling angle is less than 10°.

Embodiment 3

[0040] Add ammonia solution with a mass fraction of 28% in 0.2mol / L zinc sulfate solution and stir to form a mixed solution, so that the molar ratio of zinc atoms to nitrogen atoms is 1:20, then put it into a cellulose film and react at 120°C for 3 hours, and the reaction is over Finally, take out the cellulose film and rinse it with deionized water, and dry it in vacuum at 40°C; soak the obtained cellulose film in 0.5mol / L stearic acid ethanol solution at 35°C for 2h, wash it with ethanol after the reaction, and dry it at 40°C °C and vacuum dried.

[0041] The contact angle of the prepared film with water in air is greater than 150°, the water rolling angle is less than 10°, and the contact angle of the prepared film with oil in air is 0°, showing super lipophilicity. After the film is scraped ten times by the blade, its water contact angle is greater than 150°, and its water rolling angle is less than 10°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com