3D printing method and device for hierarchical porous material

A porous material and 3D printing technology, applied in the direction of additive processing of mixtures of solid materials and liquid materials, manufacturing auxiliary devices, 3D object support structures, etc., can solve problems such as difficult to meet performance requirements, and achieve general-purpose strong, method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

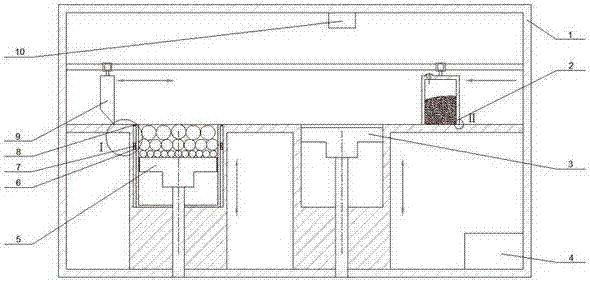

[0029] In this embodiment, iodine particles with a sublimation temperature of 77° C. are used as pore-forming particles, a photosensitive resin with a viscosity of 2000 CPS (20° C.) is used as a matrix material, the diameter of the printing hole is 50 μm-400 μm, and the height of the printed part is 10 mm.

[0030] Step 1: Use 3D modeling software (such as SolidWorks) to establish a solid model, export the STL file to the slicing software, and after data analysis of the system, generate the movement data of the scraper 9, the material box 2 along the X axis, and the feeding platform 5. The platform 3 moves data along the Z axis, the image information of the digital mask photocuring system 10, and the exposure time t.

[0031] Step 2: Add iodine particles with a relatively uniform particle size distribution gradient to the feeding platform 5, apply external vibration at a certain amplitude and frequency for 30 minutes, so that the particles are layered in an orderly manner in the hei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com