A kind of photochromic composite nano-powder and its preparation method and application

A photochromic and nano-powder technology, applied in color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of large particle size, complicated operation, neglecting the performance of molybdenum trioxide, etc. The effect of color changing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Regarding the preparation of the precursor solution, specifically, molybdates such as ammonium molybdate or sodium molybdate can be dissolved in an acid solution with a concentration greater than 2mol / L to obtain a molybdic acid solution with a concentration of 0.0083-1.588g / ml. At room temperature, stir The obtained molybdic acid solution is added with a titanium source having the same acid radical as the acid solution, such as titanium tetrachloride or titanium sulfate, to obtain a precursor solution. It is also possible to directly select a molybdenum acid solution with a concentration of 0.0083-1.588g / ml as the molybdenum source. At room temperature, stir the obtained molybdenum acid solution and add a titanium source with the same acid radical as the acid solution, such as titanium tetrachloride or titanium sulfate. Obtain the precursor solution. Regarding the concentration of the acid solution, it is preferably greater than 2 mol / L and less than 3 mol / L, so as to ...

Embodiment 1

[0035] This example describes a method for preparing molybdenum trioxide-coated titanium dioxide nanoparticles, including:

[0036] S1: Add 0.1576g ammonium paramolybdate into 10ml, 2mol / L hydrochloric acid solution to obtain soluble molybdic acid solution;

[0037] S2: Add 1ml of titanium tetrachloride to the soluble molybdic acid solution under stirring at room temperature to obtain a precursor solution;

[0038] S3: adding an appropriate amount of ammonia water dropwise to the precursor solution to make the solution pH>7, and alkalization to obtain a molybdenum-titanium sol;

[0039] S4: In the molybdenum-titanium sol, add 0.5g of hydrogen peroxide for every 1mL of titanium source, put it into a reaction kettle, react at a temperature of 150°C for 6 hours, and obtain a dispersion after the reaction is completed;

[0040] S5: Cool the dispersion to room temperature, wash with deionized water and absolute ethanol in turn, and dry to obtain molybdenum trioxide-coated titanium...

Embodiment 2

[0042] Preparation of pure titanium oxide: refer to the preparation steps of molybdenum trioxide-coated titanium dioxide nanoparticles described in Example 1, step S1 hydrochloric acid solution in Example 1 does not add ammonium paramolybdate, and all the other steps are the same as in Example 1. Prepare pure titanium oxide.

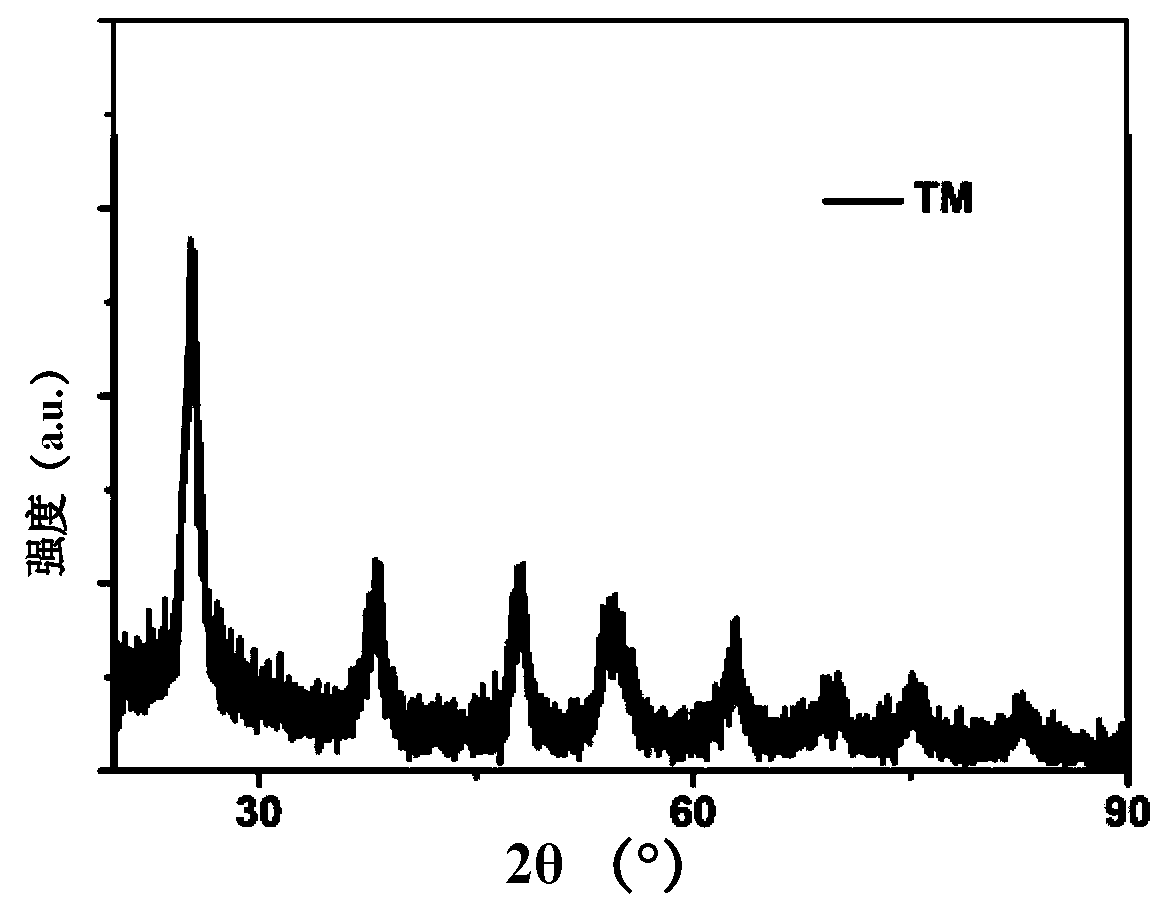

[0043] figure 1 Be the X-ray diffraction (XRD) collection of patterns of the molybdenum trioxide coated titanium dioxide nanoparticles prepared in embodiment 1, figure 2 It is the XRD pattern of the pure titanium oxide prepared in Example 2. Compared figure 1 and figure 2 It can be seen that the characteristic peak of the molybdenum trioxide-coated titanium dioxide nanoparticles prepared in Example 1 is TiO 2 , figure 1 There are no other impurity peaks appearing, indicating that the TiO in molybdenum trioxide-coated titanium dioxide nanoparticles 2 In crystalline state, MoO 3 is indefinite form.

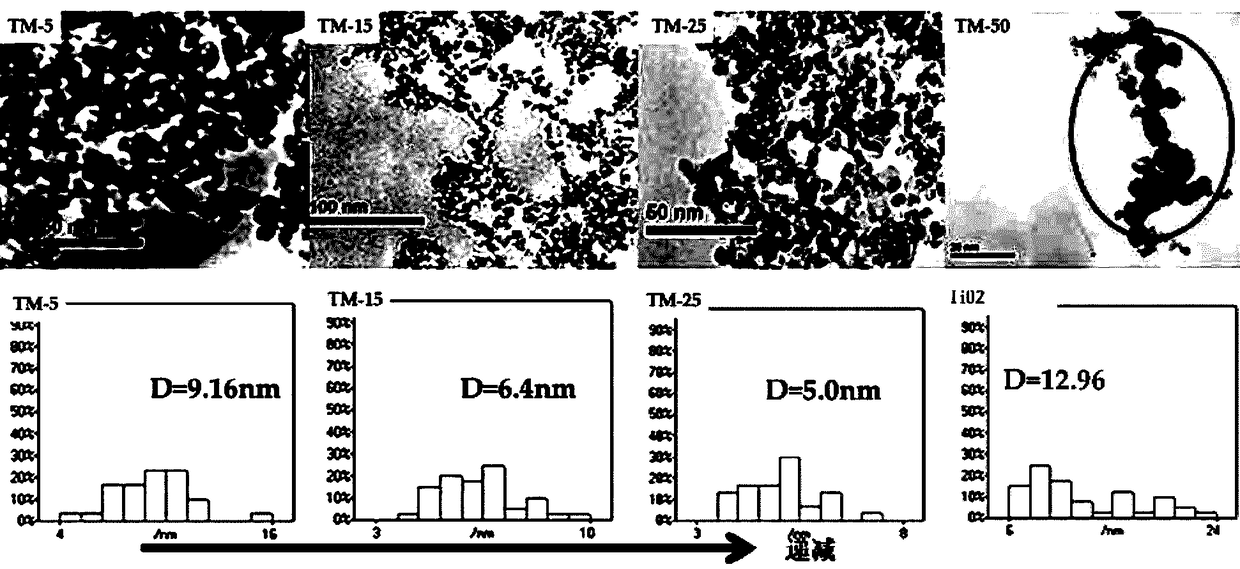

[0044] see image 3 : image 3 It is a trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com