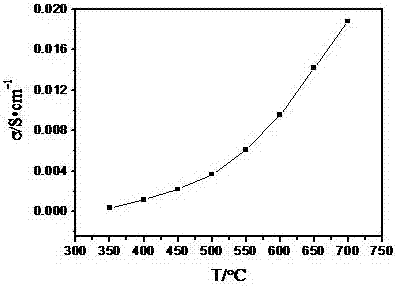

Oxygen ion conduction medium temperature solid oxide fuel cell electrolyte

A solid oxide, oxygen ion conduction technology, used in fuel cells, electrolytes, circuits, etc., can solve problems such as high requirements for connector materials, limited commercial development, and poor battery sealing performance, and achieve high conductivity and high power. The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Ce 0.87 La 0.11 Ni 0.02 o 2-α The preparation method of (CLNO)

[0028] 1. Ce 0.87 La 0.11 Ni 0.02 o 1.9 Preparation

[0029] 1) Accurately weigh the raw material Ce(NO 3 ) 3 ·6H 2 O, La(NO 3 ) 3 ·nH 2 O, Ni(NO 3 ) 3 ·6H 2 O, the complexing agent citric acid is weighed according to [n(CA):n(metal cation)=1.5:1].

[0030] 2) Ce(NO 3 ) 3 ·6H 2 O,La(NO 3 ) 3 ·nH 2 O, Ni(NO 3 ) 3 ·6H 2 O and citric acid were dissolved in deionized water respectively;

[0031] 3) Mix the above solutions and stir well

[0032] 4) Put the mixed solution obtained in step 3) into a stirrer and heat to 45°C, stir continuously at 45°C, and keep the pH value of the solution at 7 by adding ammonia water during the stirring process until a gel is formed;

[0033] 5) Move the gel into an evaporating dish and heat it on an electric furnace until self-propagating combustion occurs to form a fluffy oxide powder;

[0034] 6) Calcining at 600°C±10°C for 30±5 minutes to remove o...

Embodiment 2

[0058] Preparation of discs: Put the CLNO-LSB powder prepared in Example 1 into a mold, and under a pressure of 300 MPa, make discs with a diameter of 13 mm ± 0.1 mm and a thickness of 0.5 mm ± 0.1 mm. Heating at a heating rate of 3°C per minute to 1200°C±10°C for 4±0.1 hours to obtain the required electrolyte disc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com