Slot waveguide theory-based electromagnetic radiation suppression structure and application thereof

A technology of electromagnetic radiation and slot waveguide, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve problems affecting the working performance of integrated circuits, heat dissipation, high price, and deterioration of high-frequency electromagnetic radiation, etc., to achieve miniaturization, electromagnetic Radiation suppression, reducing the effect of electromagnetic radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

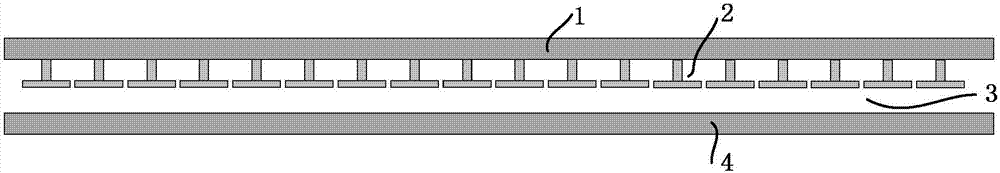

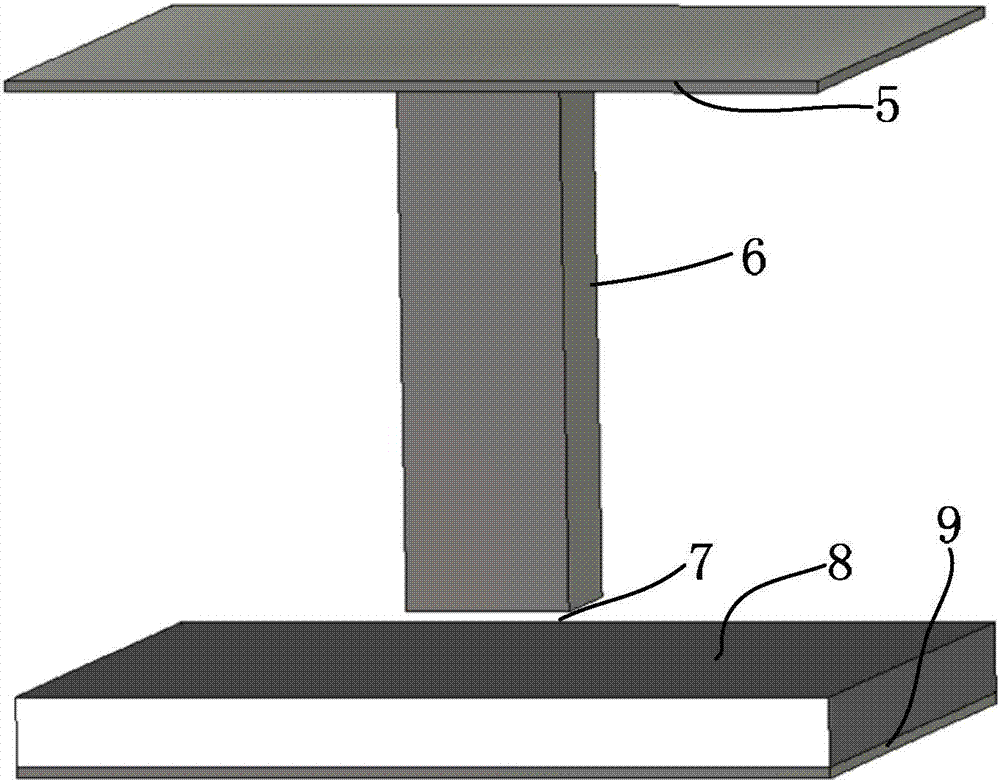

[0040] Such as Figure 4 As shown, a periodic electromagnetic bandgap EBG structure 2 is provided on the lower surface of the heat dissipation package cover 1 between the package substrate 4 and the heat dissipation package cover 1, and the periodic electromagnetic bandgap structure 2 is a pin-shaped structure uniformly distributed in a spaced array. Dimensional metal EBG structure, including a metal pin 6, the upper end of the metal pin 6 is fixed on the lower surface of the top metal plate 5 of the heat dissipation package cover or radiator, the package substrate 4 includes a dielectric layer 8 and a bottom metal plate 9, and the bottom metal plate of the package substrate 4 The board 9 serves as a metal ground plane, and there is an air gap 7 between the lower end of the metal pin 6 and the dielectric layer 8 of the packaging substrate 4 . Specific implementation According to the design requirements, adjust the period of the unit structure, the length and width of the metal...

Embodiment 2

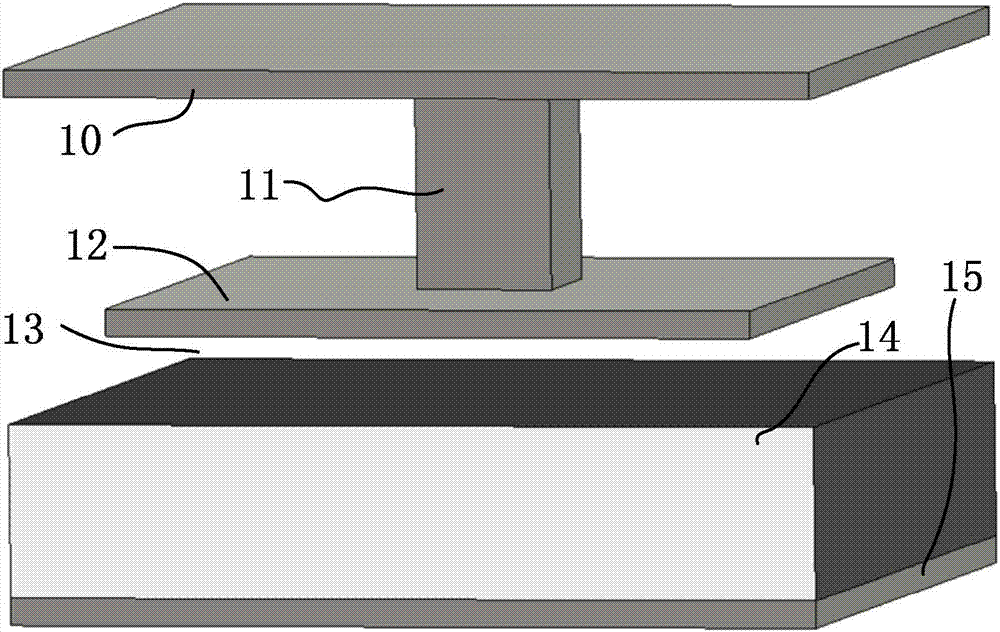

[0042] Such as Figure 5As shown, a periodic electromagnetic bandgap EBG structure 2 is provided on the lower surface of the heat dissipation package cover 1 between the package substrate 4 and the heat dissipation package cover 1, and the periodic electromagnetic bandgap structure 2 is a mushroom-shaped two-dimensional array uniformly distributed at intervals. Dimensional metal EBG structure, including metal pin 11 and metal patch 12, the upper end of metal pin 11 is fixed on the lower surface of the top metal plate 10 of the heat dissipation package cover or radiator, the lower end of metal pin 11 is connected to the center of the upper end of metal patch 12, and the metal The patch 12 is square, and there is an air gap 13 between the lower end of the metal patch 12 and the dielectric layer 14 of the package substrate 4. The package substrate 4 includes a dielectric layer 14 and a bottom metal plate 15, and the bottom metal plate 9 of the package substrate 4 serves as a metal...

Embodiment 3

[0046] Such as Figure 6 As shown, the lower surface of the heat sink 1 between the package substrate 4 and the heat sink 1 is provided with a periodic electromagnetic bandgap EBG structure 2, and the periodic electromagnetic bandgap structure 2 is a mushroom-shaped two-dimensional metal with an evenly spaced array. EBG structure.

[0047] Such as Figure 6 As shown, 19 is an inter-board heat sink commonly used in chip packaging. Its upper part is a heat dissipation tooth for heat dissipation, and its lower surface is a smooth metal surface. Thin colloidal connections. Considering the actual application scenario, a smooth metal surface is reserved in the middle part of the lower surface of the heat sink to provide enough space for the package cover and the package substrate, so the mushroom-shaped two-dimensional metal EBG structure is arranged in the ring area around the package cover, and the periodic structure The arrangement and quantity can be adjusted accordingly acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com