Lead-titanium-silicon-carbon composite and preparation method thereof

A technology of silicon-carbon composite materials and composite materials, applied in the direction of lead-acid batteries, electrical components, electrochemical generators, etc., to achieve the effect of inhibiting salinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

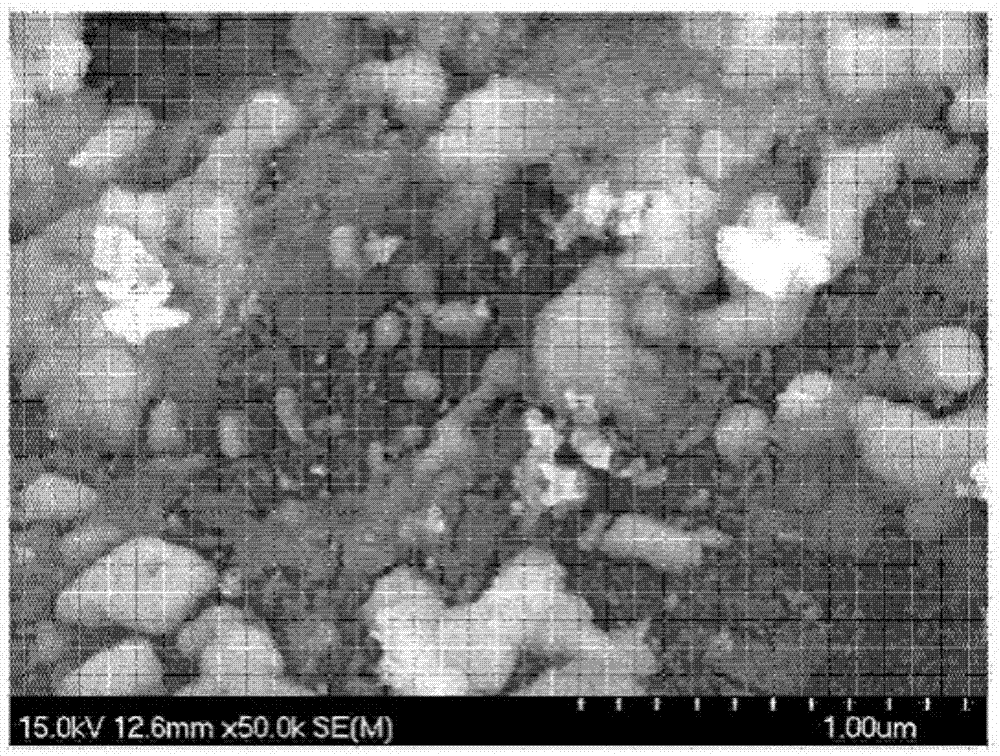

Image

Examples

preparation example Construction

[0057] An embodiment of the present invention also provides a method for preparing a lead-titanium-silicon-carbon composite material, the steps of which at least include:

[0058] S1. Preparation of silicon-carbon composite material. 80-90 parts of carbon material and 10-20 parts of silicon dioxide are evenly mixed for 2 hours to obtain a silicon-carbon composite material. The carbon material includes at least one of flake graphite, expandable graphite, colloidal graphite, acetylene black, superconducting carbon black, mesocarbon microspheres, spherical graphite, capacitor grade activated carbon, carbon fiber, carbon nanotube and graphene. In one specific embodiment, the carbon material is obtained by mixing 20-30 parts of spherical graphite, 15-40 parts of acetylene black, 15-50 parts of activated carbon and 15-40 parts of carbon fiber. In the second specific embodiment, the carbon material is obtained by mixing 20-30 parts of spherical graphite, 20-30 parts of acetylene bla...

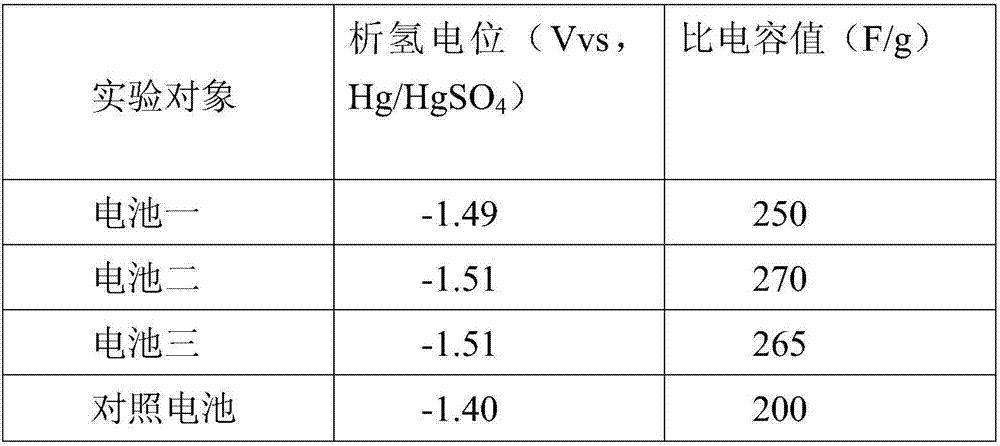

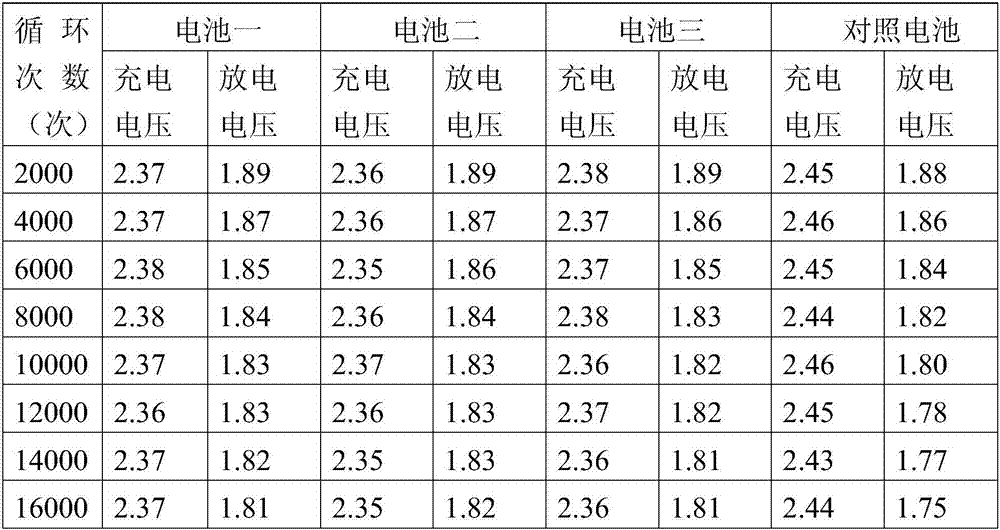

Embodiment 1

[0064] This embodiment discloses a method for preparing a lead-titanium-silicon-carbon composite material, and the specific steps include:

[0065] S10, preparing a silicon-carbon composite material. Mix carbon materials according to the following mass ratios:

[0066] Spherical graphite is 25%, its carbon content is greater than 99%, the particle size D50 is 15-20um, and the specific surface area is 4-6.5m 2 / g;

[0067] Acetylene black is 25%, its average particle size is 25-30nm, and its specific surface area is 250-300m 2 / g;

[0068] Activated carbon is 25%, its pore size is 2-2.2nm, and its pore volume is 1-1.2cm 3 / g, the specific surface area is 2000m 2 / g or more, the inorganic mass specific capacitance is 280F / g;

[0069] Carbon fiber is 25%, and its specific surface area is 15-20m 2 / g, the length is 5-8um, the diameter is 150nm, the conductivity is 1*10 -4 Ω / cm;

[0070] A mixed material is obtained after uniform stirring, and silicon dioxide is added to t...

Embodiment 2

[0075] In the preparation method disclosed in this embodiment, the difference from the first embodiment lies in the steps of preparing the silicon-carbon composite material, and the rest of the specific steps are the same.

[0076] S11, preparing a silicon-carbon composite material. Mix carbon materials according to the following mass ratios:

[0077] Spherical graphite is 25%, its carbon content is greater than 99%, the particle size D50 is 15-20um, and the specific surface area is 4-6.5m 2 / g;

[0078] Acetylene black is 35%, its average particle size is 25-30nm, and its specific surface area is 250-300m 2 / g;

[0079] Activated carbon is 20%, its pore size is 2-2.2nm, and its pore volume is 1-1.2cm 3 / g, the specific surface area is 2000m 2 / g or more, the inorganic mass specific capacitance is 280F / g;

[0080] Carbon fiber is 35%, and its specific surface area is 15-20m 2 / g, the length is 5-8um, the diameter is 150nm, the conductivity is 1*10 -4 Ω / cm;

[0081] A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com