Composite potassium hydrogen persulfate disinfectant and preparation method thereof

A technology of potassium hydrogen persulfate and disinfectant, applied in the directions of disinfectants, botanical equipment and methods, biocides, etc., can solve the problems of narrow antibacterial spectrum, strong irritation, high corrosiveness, etc. The effect of strong dirt and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

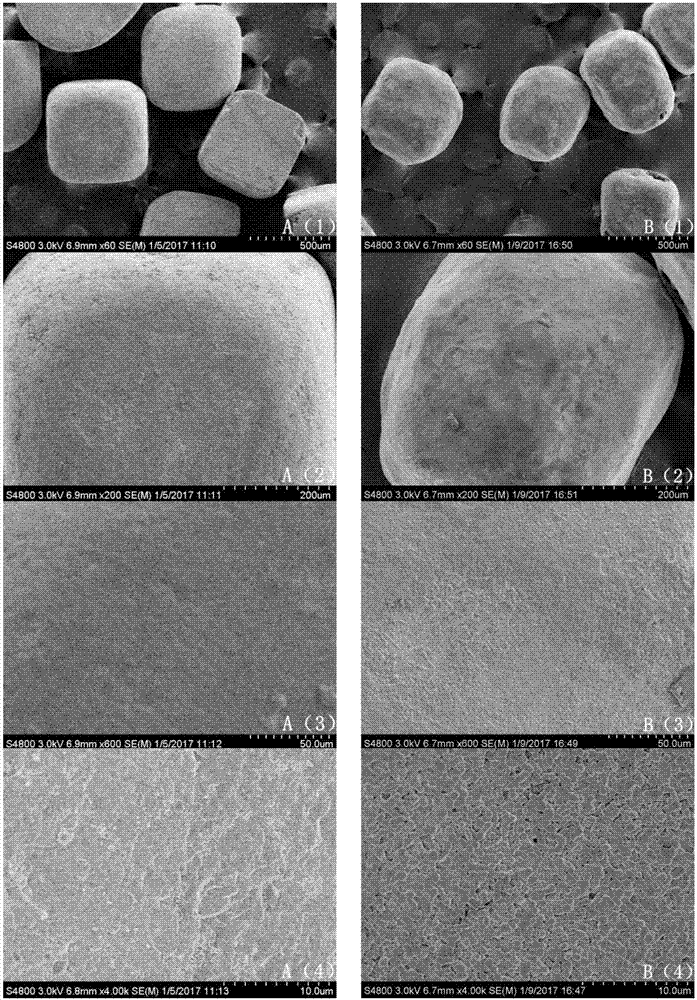

[0045] Embodiment 1 sodium chloride wrapping 100Kg

[0046] The sodium chloride wrapper in this embodiment is composed of a wrapped core material and a film-forming agent for wrapping. The wrapped core material is granular sodium chloride salt with a particle size of 250 μm to 550 μm. The film agent is sodium alginate.

[0047]The preparation of the sodium chloride wrapper of the present embodiment adopts the fluidized bed coating method, and the specific steps are as follows:

[0048] (1) The film-forming agent sodium alginate is mixed with water according to the mass ratio of 0.02:1 to form a film-forming solution with a certain viscosity;

[0049] (2) The film-forming solution and sodium chloride are sprayed into the sodium chloride placed in the bottom spray of the fluidized bed according to the mass ratio of 4:1 by the film-forming solution, and coated to make a sodium chloride wrapping, Among them, the parameters of the fluidized bed are set as follows: air inlet tempe...

Embodiment 2

[0051] Embodiment 2 sodium chloride wrapping 50Kg

[0052] The sodium chloride wrapping in this embodiment is composed of a wrapped core material and a film-forming agent for wrapping. The wrapped core material is granular sodium chloride salt with a particle size of 380 μm to 550 μm. The film agent is sodium alginate.

[0053] The sodium chloride wrapping of this embodiment is prepared by fluidized bed coating method, and the specific steps are as follows:

[0054] (1) The film-forming agent sodium alginate is mixed with water according to the mass ratio of 0.02:1 to form a film-forming solution with a certain viscosity;

[0055] (2) The film-forming solution and sodium chloride are sprayed into the sodium chloride placed in the bottom spray of the fluidized bed according to the mass ratio of 4:1 by the film-forming solution, and coated to make a sodium chloride wrapping, Among them, the fluidized bed parameters are set as follows: air inlet temperature 45°C; fan frequency ...

Embodiment 3

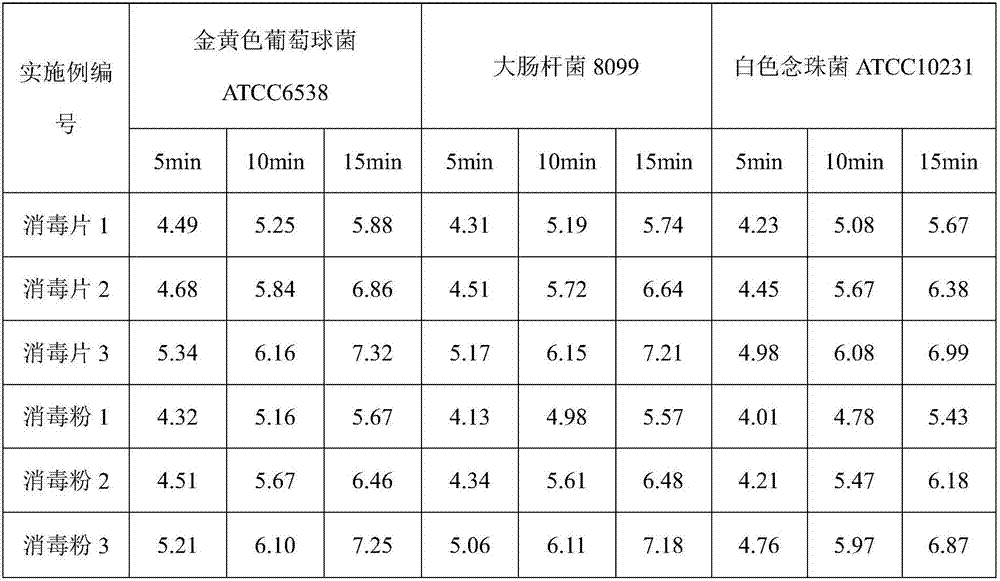

[0056] Embodiment 3 compound potassium hydrogen persulfate disinfectant

[0057] The components of this embodiment are calculated by weight percent: potassium persulfate 50%, sodium chloride wrapping 3% (from embodiment 1), alkyl glycoside powder 5%, solid acidic agent 19%, effervescent agent 8 %, lubricant 1.24%, metal chelating agent 5%, anti-caking agent 8.62%, flavoring agent 0.06%, pigment 0.08%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com