Self-healing polymeric water-treatment membrane and preparation method thereof

A water treatment membrane and polymer technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as rupture, achieve the effects of repairing membrane cracks, improving mechanical strength, and avoiding further damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the self-healing polymer water treatment membrane comprises the following steps:

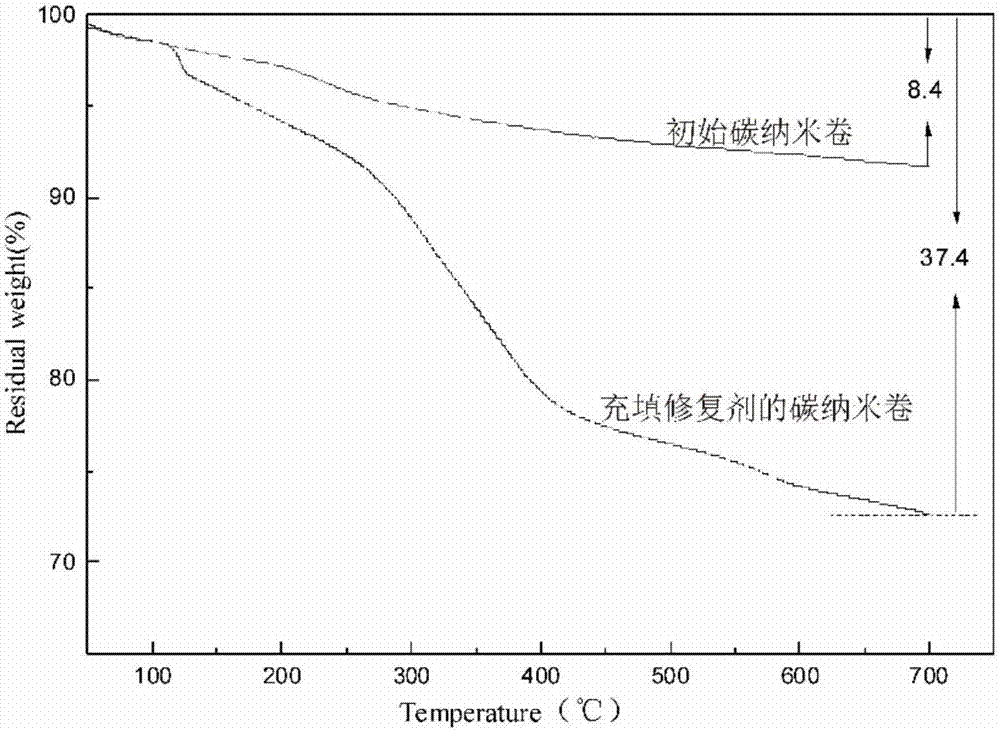

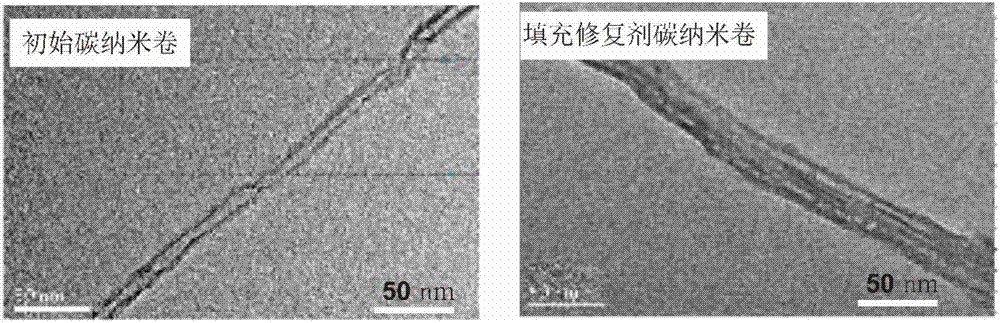

[0027] (1) Preparation of dispersion: by pretreating carbon nanoscrolls at high temperature under argon flow, toluene diisocyanate (TDI) and diphenylmethane diisocyanate-diethylene glycol (MDI) (volume ratio 1:1) Stir at room temperature in a nitrogen atmosphere for 1-2 hours, slowly add carbon nanocoils with a diameter of 0.1 μm and a length of 100 μm after high-temperature pretreatment, and the mass ratio of carbon nanocoils to repairing agent is 1:49. Ultrasonic dispersion of nanoscrolls at -5°C low temperature, after filtration, add 5 g of the carbon nanoscrolls containing repairing agent to 50 g of acetone containing 0.2% sodium dodecylbenzene sulfate, and mix the acetone solution with N,N-dimethyl formaldehyde Amides were ultrasonically mixed at a volume ratio of 10:100 to prepare a carbon nanoscroll dispersion with a mass percentage of carbon nanoscrolls o...

Embodiment 2

[0031] The preparation method of the self-healing polymer water treatment membrane comprises the following steps:

[0032] (1) Preparation of dispersion: by pretreating carbon nanoscrolls at high temperature under argon flow, toluene diisocyanate (TDI) and diphenylmethane diisocyanate-diethylene glycol (MDI) (volume ratio 1:1) Stir at room temperature in a nitrogen atmosphere for 1-2 hours, slowly add high-temperature pretreated carbon nanoscrolls with a diameter of 0.1 μm and a length of 100 μm, the mass ratio of carbon nanoscrolls and repairing agent is 5:95, and the repairing agent and carbon Ultrasonic dispersion of nanoscrolls at low temperature -5°C, after filtration, add 5 g of the carbon nanoscrolls to 50 g of acetone containing 0.1% Tween-85, and mix the acetone solution with N,N-dimethylformamide at a volume ratio of 20:100 A carbon nanoscroll dispersion liquid with a carbon nanoscroll mass percentage of 1.6% was prepared by ultrasonic mixing.

[0033] (2) Preparati...

Embodiment 3

[0036](1) Preparation of dispersion: by pretreating carbon nanoscrolls at high temperature under argon flow, toluene diisocyanate (TDI) and diphenylmethane diisocyanate-diethylene glycol (MDI) (volume ratio 1:1) Stir at room temperature for 1-2 hours in a nitrogen atmosphere, slowly add carbon nanoscrolls with a diameter of 0.1 μm and a length of 100 μm, the mass ratio of carbon nanoscrolls and repairing agent is 10:90, and the repairing agent and carbon nanoscrolls at low temperature -5 ℃ Ultrasonic dispersion, after filtration, add 10g of the carbon nanoscrolls to 50g of acetone containing 0.5% sodium dodecylbenzene sulfate, and ultrasonically mix the acetone solution with N,N-dimethylformamide at a volume ratio of 10:100 A carbon nanoscroll dispersion liquid with a mass percentage of carbon nanoscrolls of 1.8% was obtained.

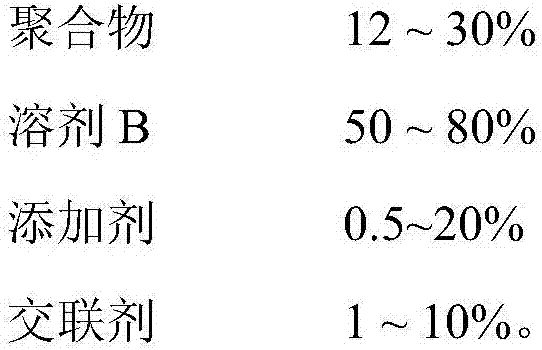

[0037] (2) Preparation of casting solution: dissolve polyvinylidene fluoride at 60°C in a mixed solvent composed of acetone and dimethylacetamide (the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com